Shaftless hollow brushless motor

A brushless motor and hollow technology, which is applied in the field of electric laser head and laser radar, can solve the problems of low space utilization, large volume, low efficiency, etc., and achieve the effect of saving laser dust and overall space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below by means of the accompanying drawings and examples.

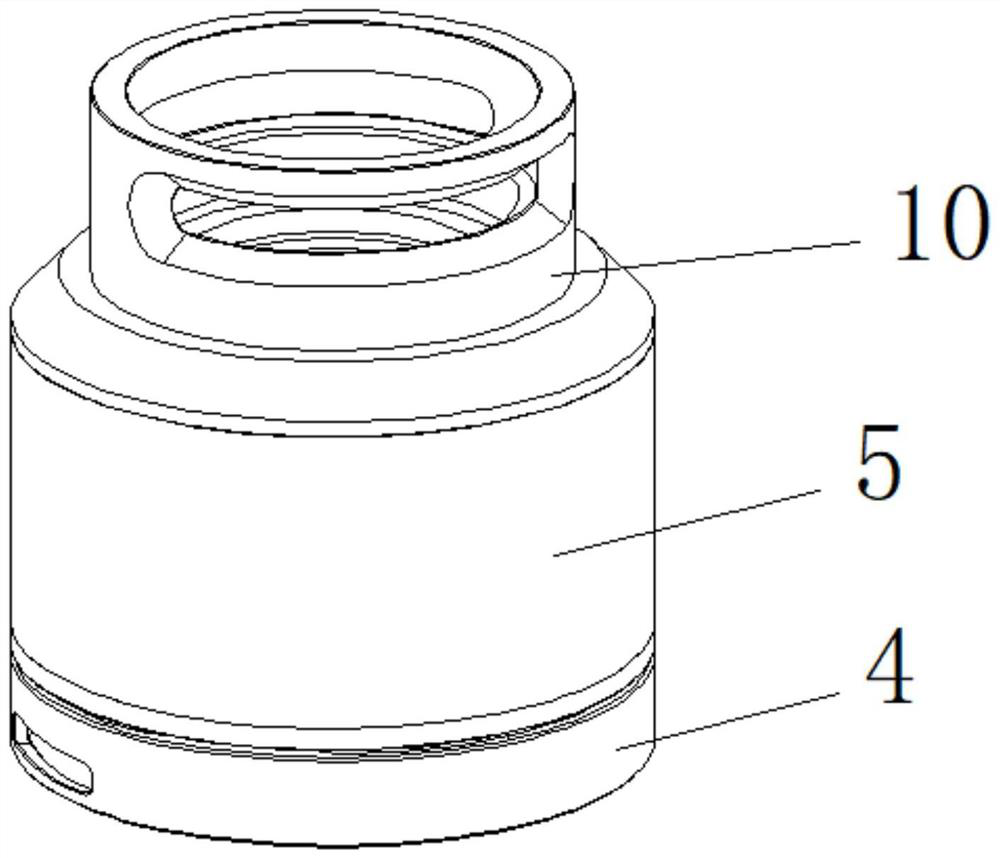

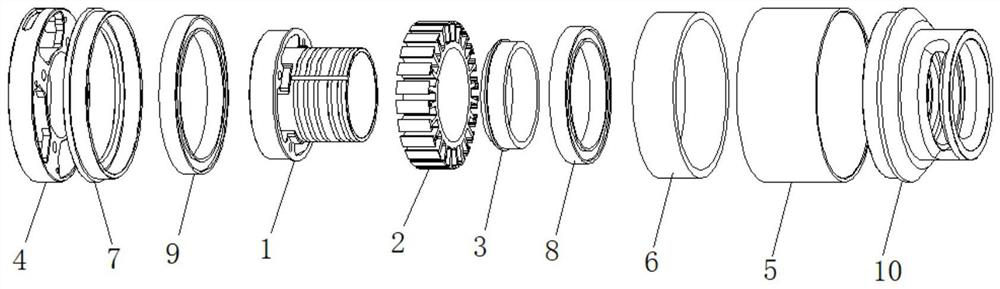

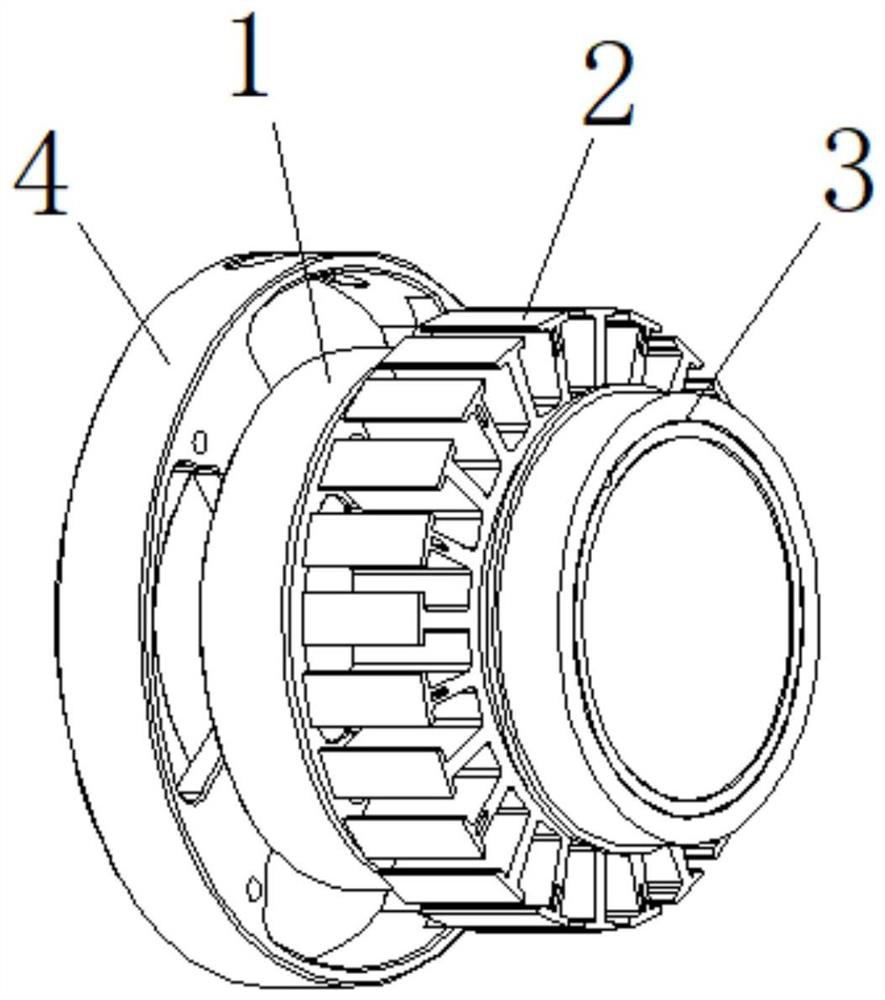

[0027] An embodiment of the present invention provides a shaftless hollow brushless motor, such as Figure 1-8 As shown, the steel ring 5 is included, the top of the steel ring 5 is provided with an integrated upper cover 10, the bottom of the steel ring 5 is provided with a drive base 4, and a lower cover 7 is installed on one side of the drive base 4, and the inner side of the lower cover 7 A second bearing 9 is installed, a stator fixing seat 1 is installed on one side of the driving base 4, a stator core 2 is set on the outer side of the stator fixing seat 1, a fixed ring seat 3 is arranged on the outer side of the stator fixing seat 1, and a steel ring 5 A magnetic ring 6 is sheathed inside, and a first bearing 8 is provided between the magnetic ring 6 and the integral upper cover 10 .

[0028] In this embodiment, by adopting the three-phase brushless motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com