Fluid control device

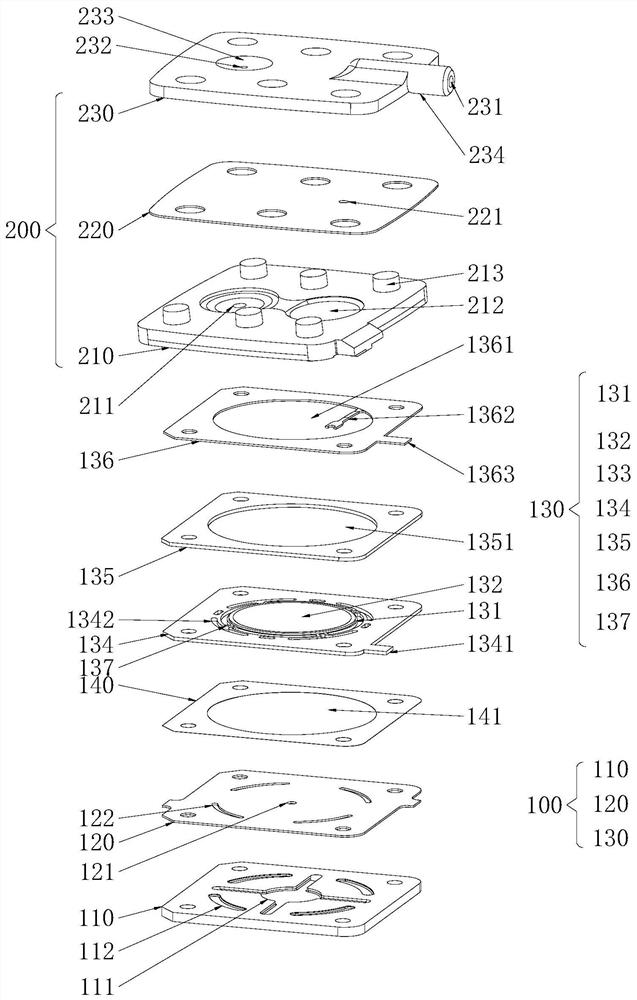

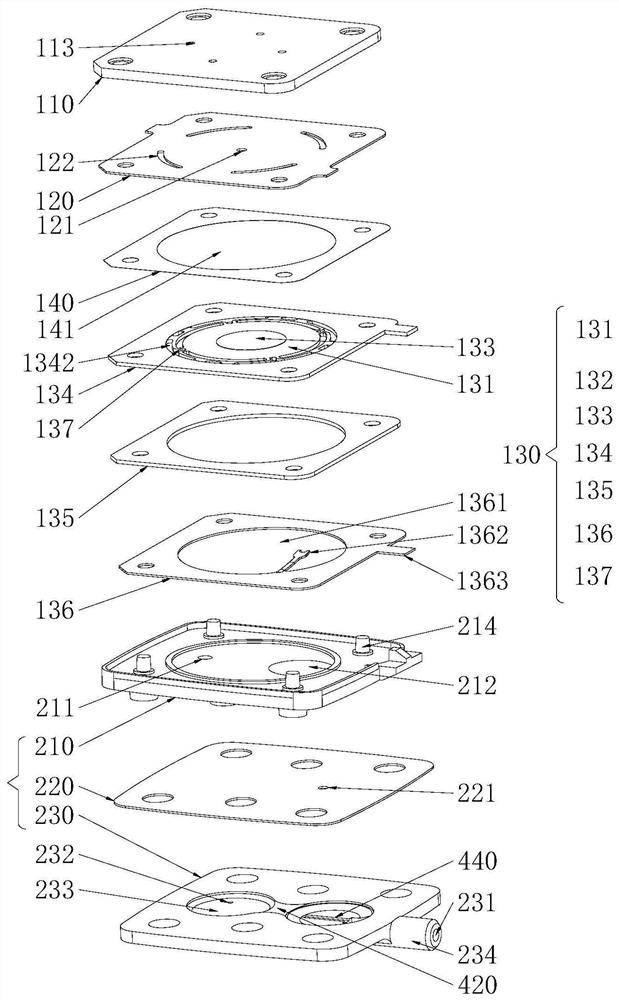

A fluid control device and control valve technology, which is used in liquid variable capacity machinery, variable capacity pump components, and pumps with flexible working elements, etc., which can solve the problems of many sealing points, insufficient compact structure, and large space occupation, etc. problems, to achieve the effect of reducing the sealing position, compact structure and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

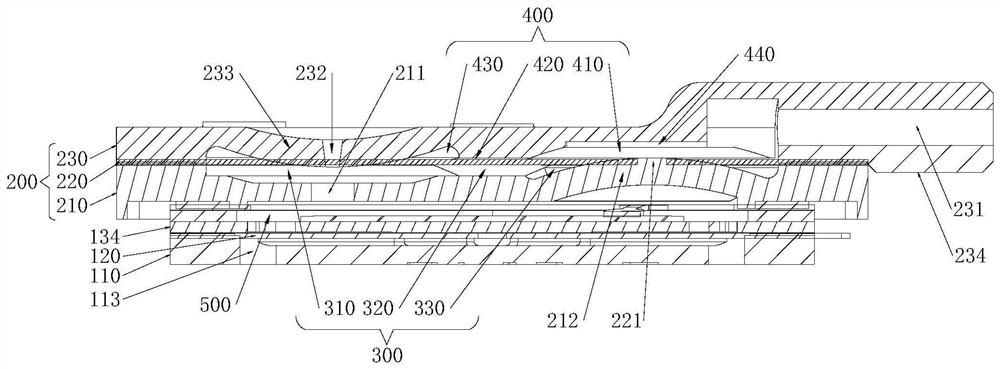

[0101] Surfaces of the first protruding portion 212 and the second protruding portion 233 are arc-shaped. Such arrangement can make the sealing connection between the diaphragm 220 and the first protruding portion 212 tighter in a natural state, and the sealing connection between the diaphragm 220 and the second protruding portion 233 is also tighter.

[0102] As a further preferred embodiment:

[0103] The air outlet hole 231 is disposed in the air outlet pipe 234 of the valve body upper shell 230, and the air outlet pipe 234 extends along the horizontal direction; thus, the air outlet pipe 234 is arranged in the horizontal direction to further compress the space of the fluid control device in the height direction. At the same time, in order to further compress the space in the height direction, the base plate 110 is provided with an air-introduction groove extending in the horizontal direction, and the two ends of the air-induction groove are respectively connected to the op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com