Energy-intensive timber frame structural system

A wood frame and high energy consumption technology, which is applied in the field of high energy consumption wood frame structure system, can solve the problems of cumbersome processing procedures, influence of normal use of buildings, and small rigidity of wooden beams, so as to achieve clear force, simple strength verification, and improved Seismic performance and practicality, the effect of solving deflection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with accompanying drawing.

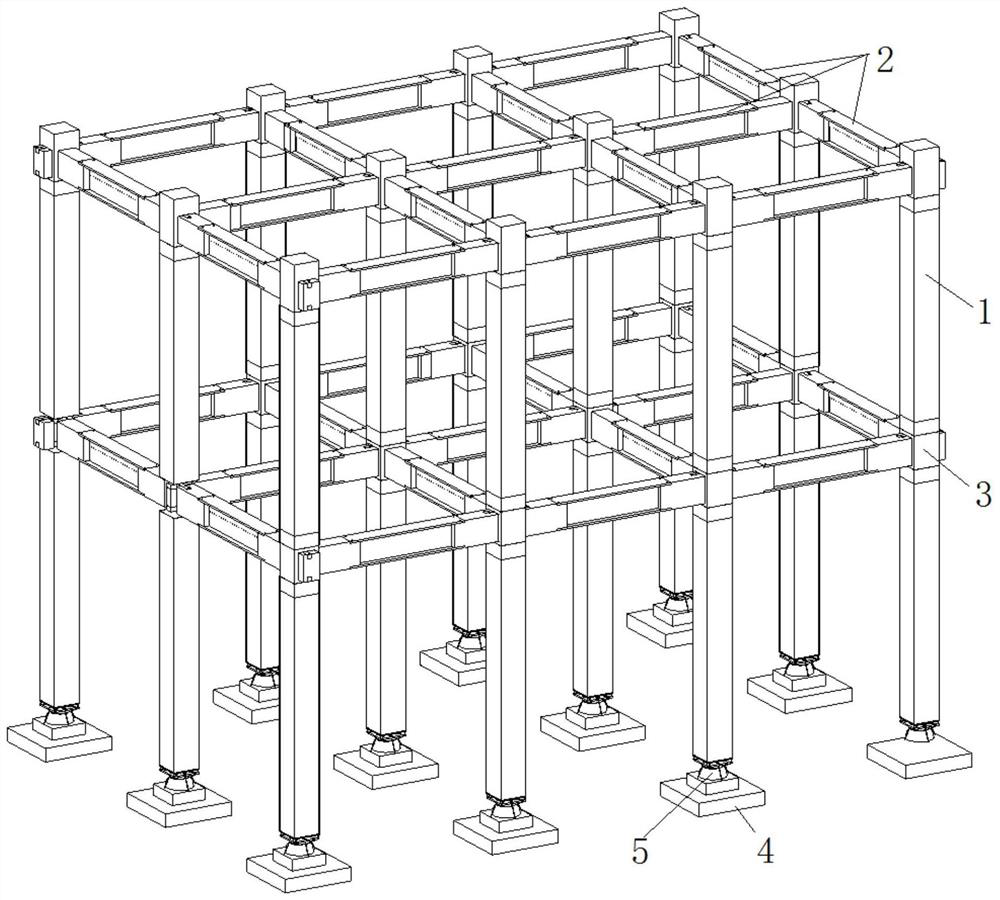

[0055] Such as figure 1 As shown, the high energy-consuming wood frame structure system of the present invention includes a composite column 1, a composite beam 2, a node connection assembly 3, a foundation 4 and a foundation connector 5, and between the upper and lower adjacent composite columns 1 and the composite column 1 The composite beams 2 arranged horizontally are all connected by node connection components 3 , and the composite wooden column 1 at the lowest end is installed on the foundation 4 through the foundation connector 5 .

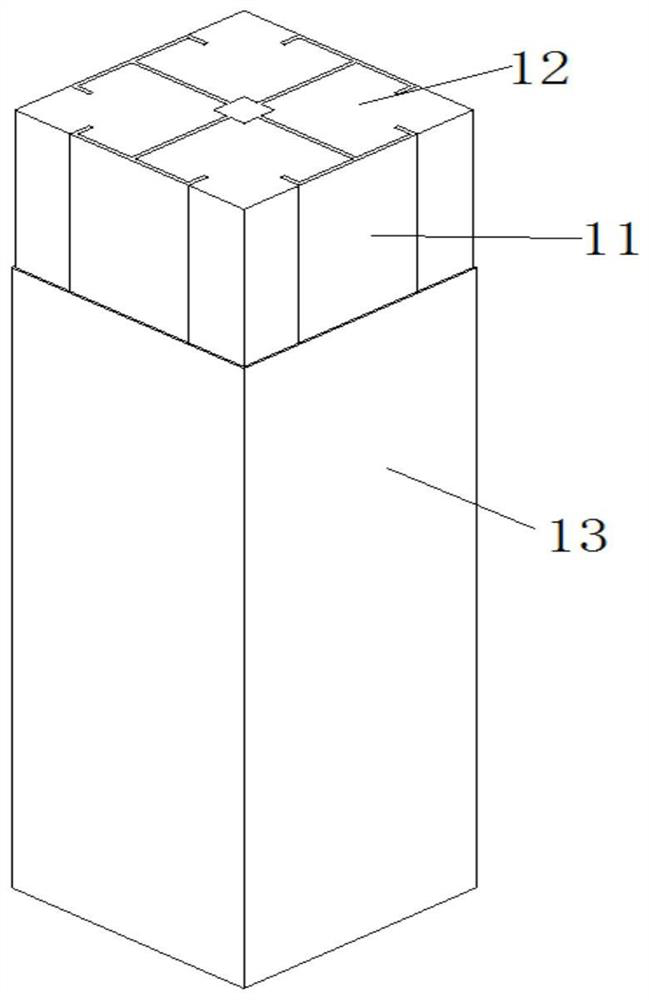

[0056] Such as figure 2 As shown, the composite column 1 includes steel inserts 11 and filler wood blocks 12 , and the periphery of the composite column 1 is also covered with FRP fiber cloth 13 .

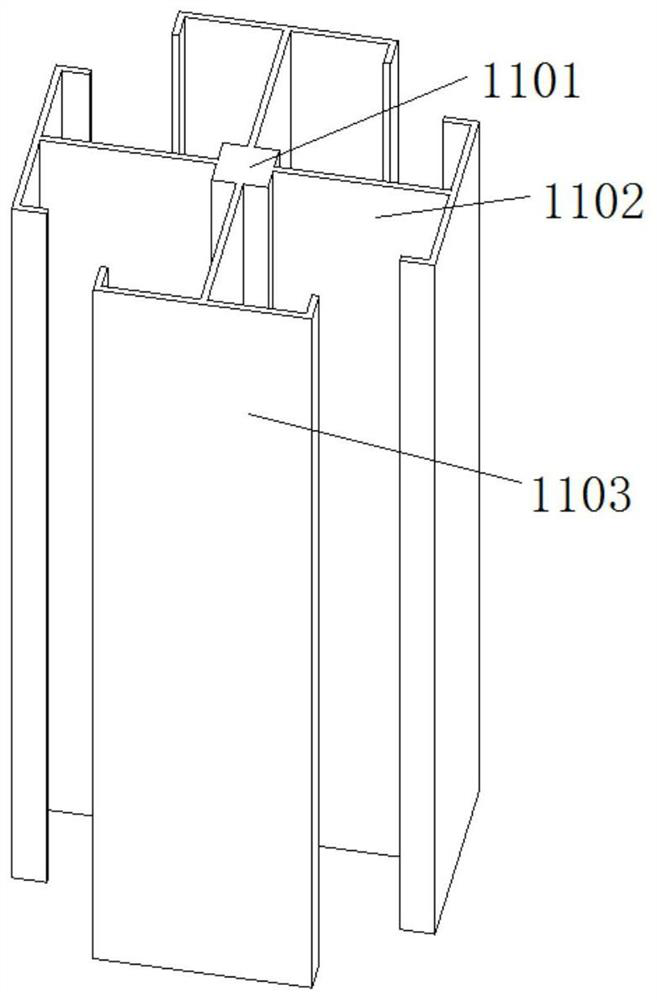

[0057] Such as Figure 3-4 As shown, the steel insert 11 includes a central connecting column 1101, a connecting plate 1102 and a surrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com