Organic solid waste biological fermentation drying system

A technology of biological fermentation and drying system, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, solid-phase fermentation bioreactor, etc. , Large footprint and other issues, to achieve the effect of improving the level of intensification, reducing energy consumption of drying, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

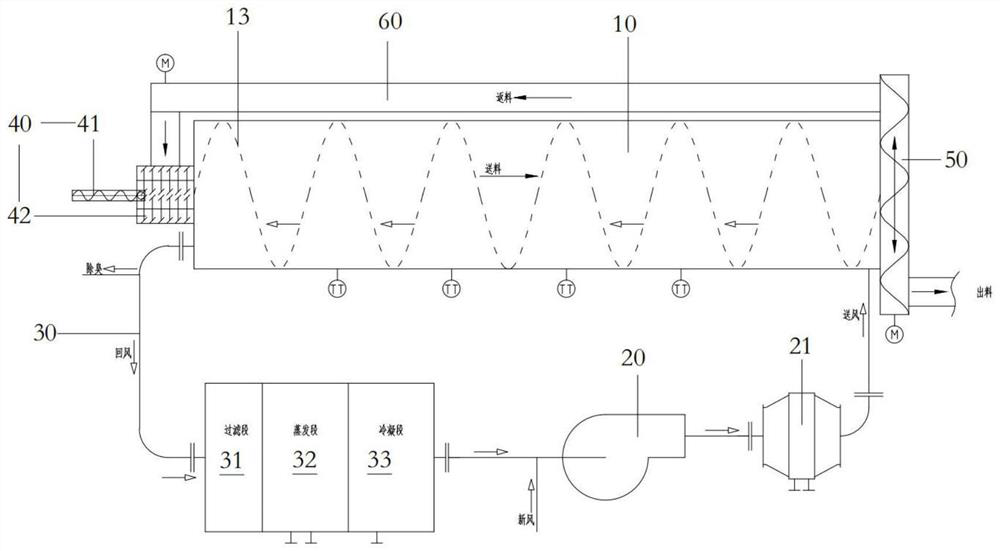

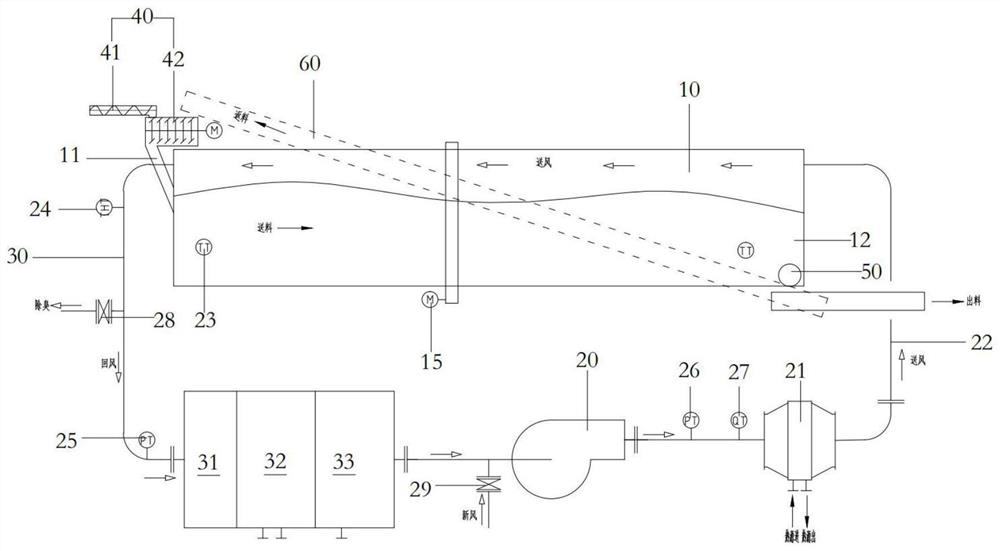

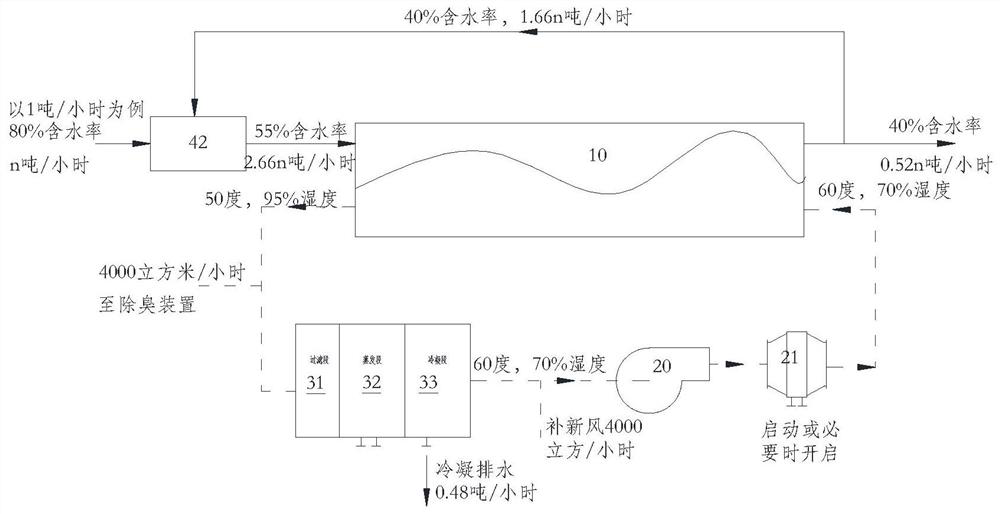

[0024] see figure 1 , and combined with figure 2 As shown, a biological fermentation and drying system for organic solid waste in the present invention includes a drum 10 and an induced draft fan 20. The two ends of the drum 10 are respectively provided with a feed port 11 and a discharge port 12, and the drum 10 is horizontal. Set and the bottom is provided with a support roller, the drum 10 is driven by a motor 15 to drive it to rotate, the inner surface of the drum 10 is provided with a spiral drain plate 13, and a plurality of stirring plates are installed on the drain plate 13 at intervals. Rod, the feed port 11 of the drum 10 is externally connected to the return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com