Gluing-free environment-friendly odorless damping plate and preparation method thereof

A damping board, odorless technology, applied in the field of damping boards, can solve problems such as low production efficiency, lack of lamination performance, complex product process, etc., to reduce the process of glue coating, excellent weather resistance, and improve adhesion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

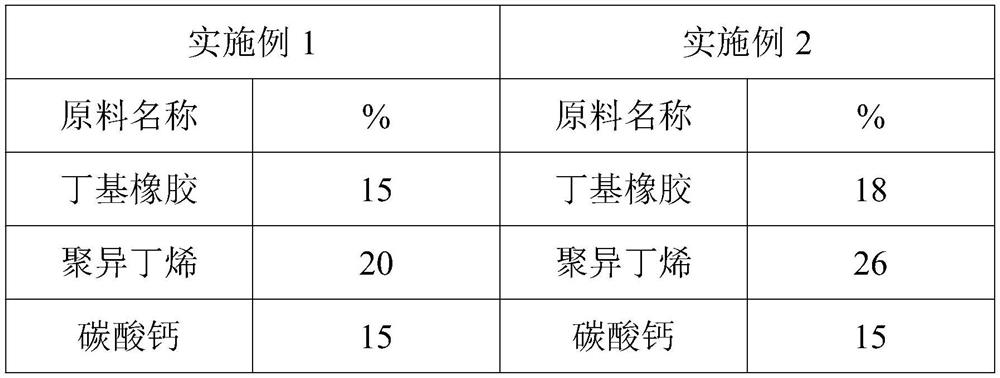

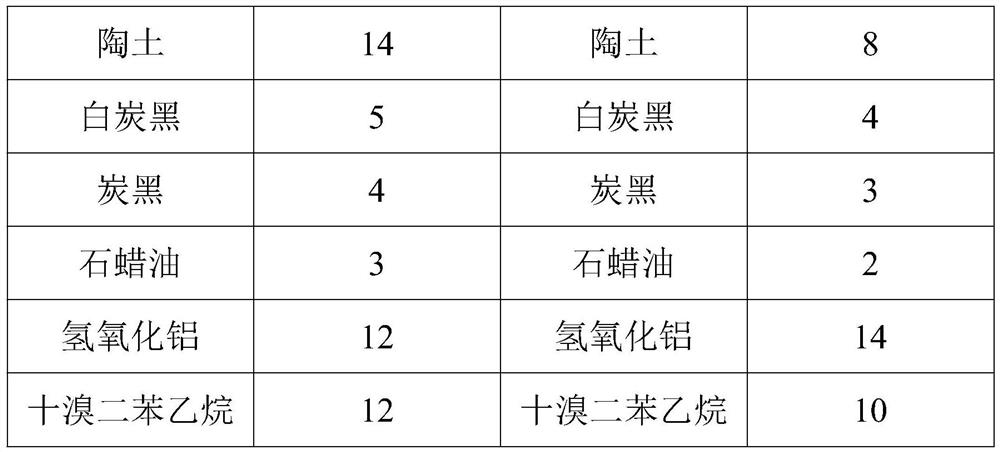

Embodiment 1

[0017] An environmentally friendly and odorless damping plate free of glue coating, the damping plate is composed of 15% butyl rubber, 20% polyisobutylene, 15% calcium carbonate, 14% clay, and 5% white carbon black in terms of mass percentage. %, carbon black 4%, paraffin oil 3%, aluminum hydroxide 12%, decabromodiphenylethane 12%.

[0018] The preparation method of above-mentioned embodiment 1 is:

[0019] S1: Heat and stir the formulated amount of butyl rubber, paraffin oil, aluminum hydroxide, and decabromodiphenylethane. When the temperature reaches 50-120°C, add the formulated amount of polyisobutylene, and mix well;

[0020] S2: Then add the filler in the formula amount, continue to stir until it is completely absorbed and mixed, and the temperature of the material is cooled to room temperature;

[0021] S3: Mix the product obtained in S2 with paraffin oil and aluminum hydroxide according to the formula ratio, and stir at room temperature for 3-5 hours to obtain the dam...

Embodiment 2

[0023] An environmentally friendly and odorless damping plate free of glue coating, the damping plate is composed of 18% butyl rubber, 26% polyisobutylene, 15% calcium carbonate, 8% clay, and 4% white carbon black in terms of mass percentage. %, carbon black 3%, paraffin oil 2%, aluminum hydroxide 14%, decabromodiphenylethane 10%.

[0024] The preparation method of above-mentioned embodiment 2 is:

[0025] S1: Heat and stir the formulated amount of butyl rubber, paraffin oil, aluminum hydroxide, and decabromodiphenylethane. When the temperature reaches 50-120°C, add the formulated amount of polyisobutylene, and mix well;

[0026] S2: Then add the filler in the formula amount, continue to stir until it is completely absorbed and mixed, and the temperature of the material is cooled to room temperature;

[0027] S3: Mix the product obtained in S2 with paraffin oil and aluminum hydroxide according to the formula ratio, and stir at room temperature for 3-5 hours to obtain a dampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com