A high-speed filling and sealing device for soft liquid bag hose

A technology for sealing devices and hoses, applied in packaging, liquid materials, transportation and packaging, etc., can solve problems such as high-speed jets, and achieve the effects of simple structure, stable and reliable mechanism, practical and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

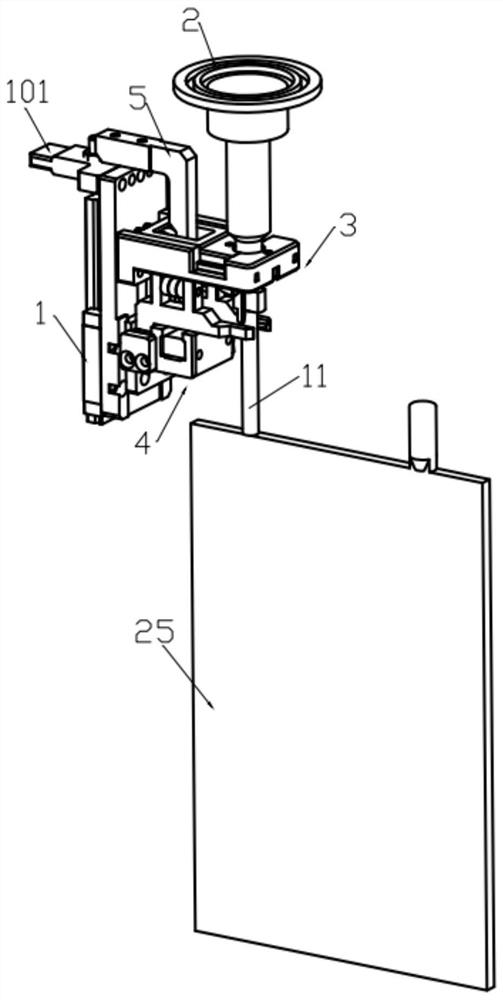

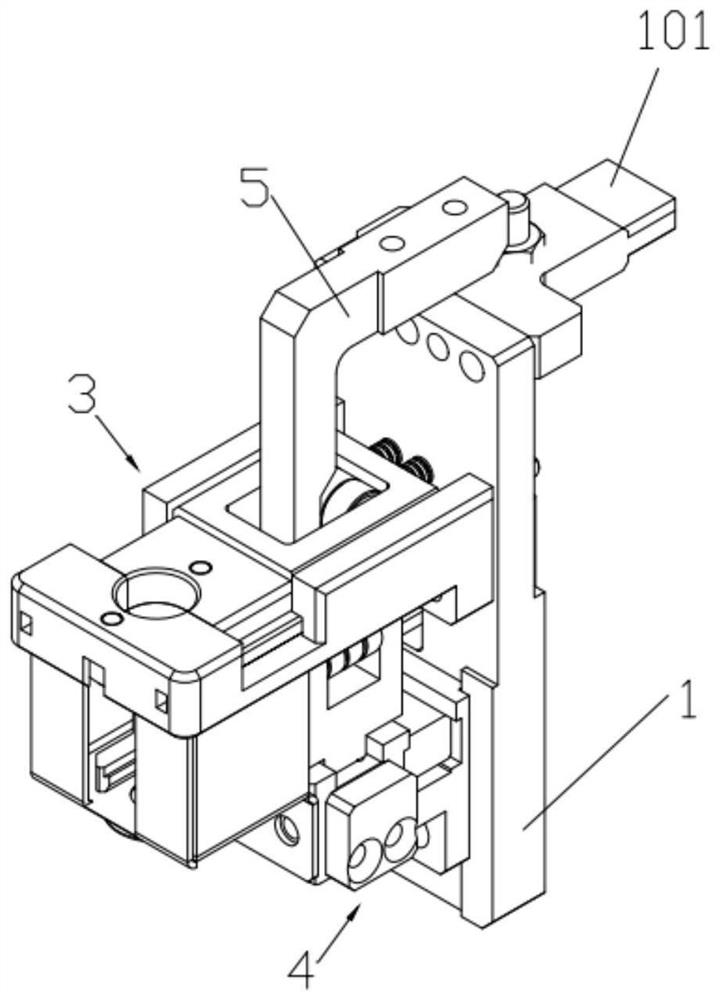

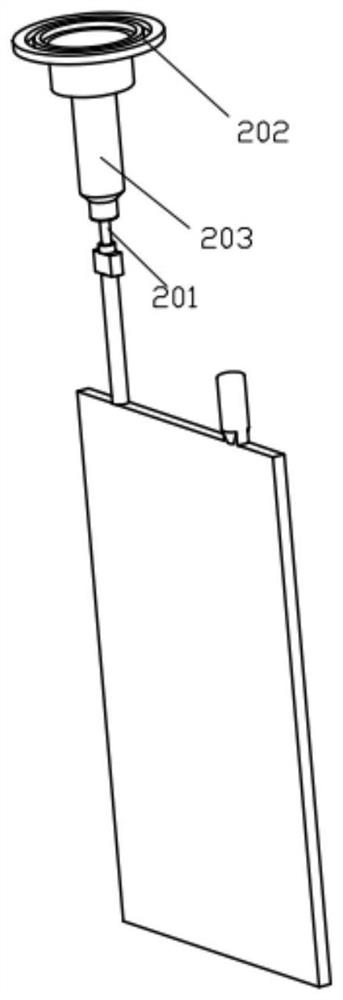

[0049] See Figure 1-10 The present invention provides a technical solution:

[0050] Please refer to Figure 1-7 , A high-speed filling sealing device for a soft liquid bag hose, including a bracket 1, a filling assembly 2, a pin carrier 3, a jaw assembly 4, and an actuator 5, the pin carrier 3 and the clamp. The claw assembly 4 is mounted on the bracket 1 and set up in the vertical direction of the bracket 1;

[0051] The pin carrier 3 includes a fixing element 6, a movable element 7, a first insertion member 8, and a second insertion member 6 mounted on the stent 1, and the active element 7 is provided. There is a window 301, the movable element 7 slides in the fixing element 6 and constitutes a carrier body having a circular passage 10 in each other, the first insertion member 8 is disposed on the bottom wall of the fixing element 6. The second dose member 9 is disposed on the bottom wall of the movable element 7, the first insertion member 8 and the second plug member 9 constit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com