Miniaturized full-cloth copilot airbag box body

An airbag and box body technology, which is applied in vehicle safety arrangement, pedestrian/passenger safety arrangement, transportation and packaging, etc., can solve the problem of difficult control of the mass production quality of airbags, failure to meet the body and space, and difficulty in ensuring the consistency of the box body and other issues, to achieve the effect of shortening the research and development cycle, good product consistency, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

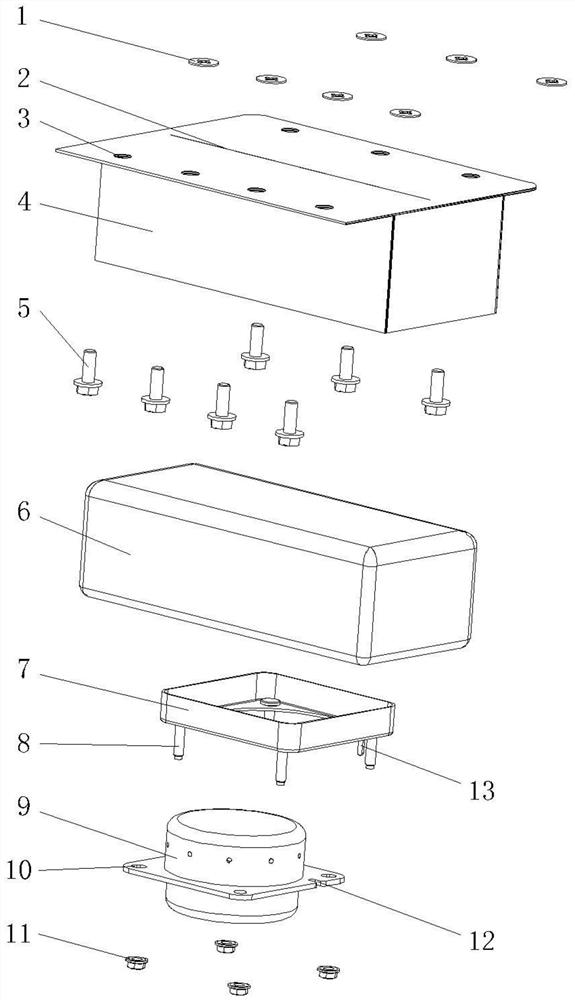

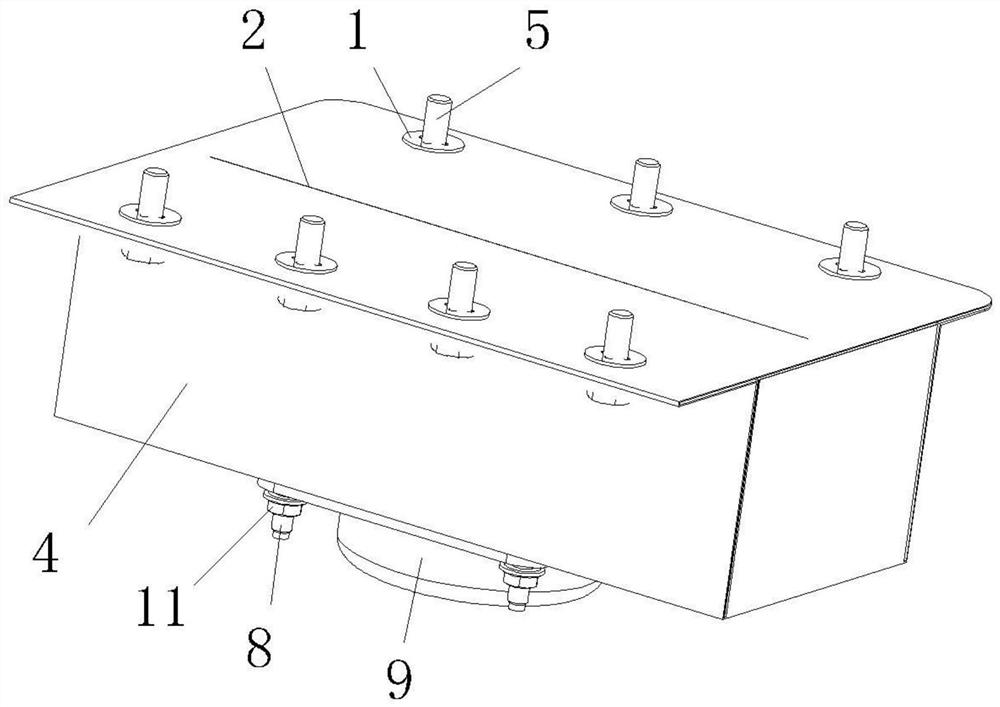

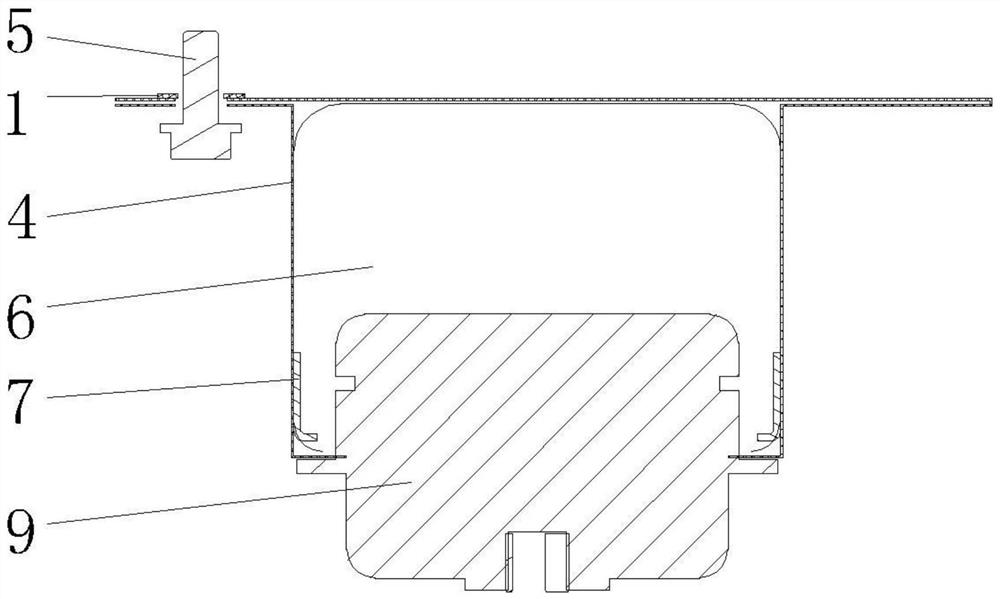

[0020] Such as Figure 4 As shown, the present invention includes an airbag box body 4, which is made of PA66 material, and the airbag box body 4 is fixed and formed by sewing thread 14. The airbag box body 4 is in the shape of a quadrangular prism. The central position of the top of the airbag box body 4 is provided with a tear weakening line 2 , and the length of the tear weakening line 2 is less than the length of the airbag box body 4 . Such as figure 1 and figure 2 As shown, the top of the airbag box body 4 is provided with folded edges near the two sides. A first installation hole 3 is provided on the folded edge. There are two flanges, one flange has four first installation holes 3, and the other flange has three first installation holes 3. A bolt 5 is arranged in the first installation hole 3 , and a paper spacer 1 , a metal hanger bracket and a nut 11 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com