Workshop dust treatment device and treatment method thereof

A dust treatment and workshop technology, applied in separation methods, chemical instruments and methods, heating methods, etc., can solve problems such as limited space for action, inability to clean large workshops, no dust reduction, cleaning, and purification devices, etc., to improve the utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

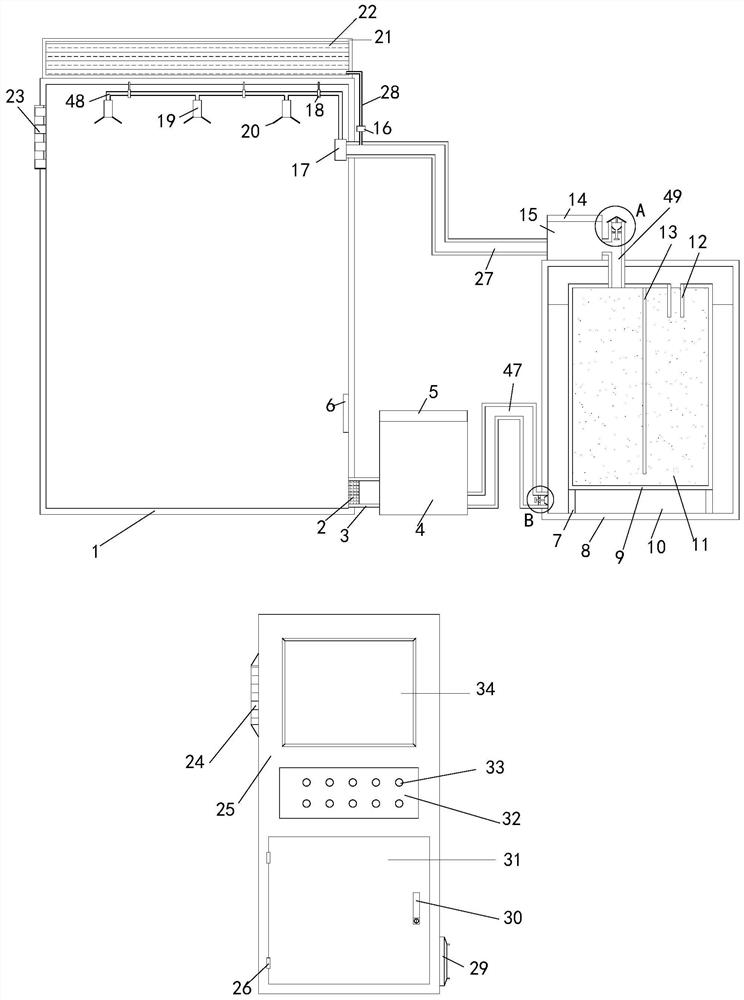

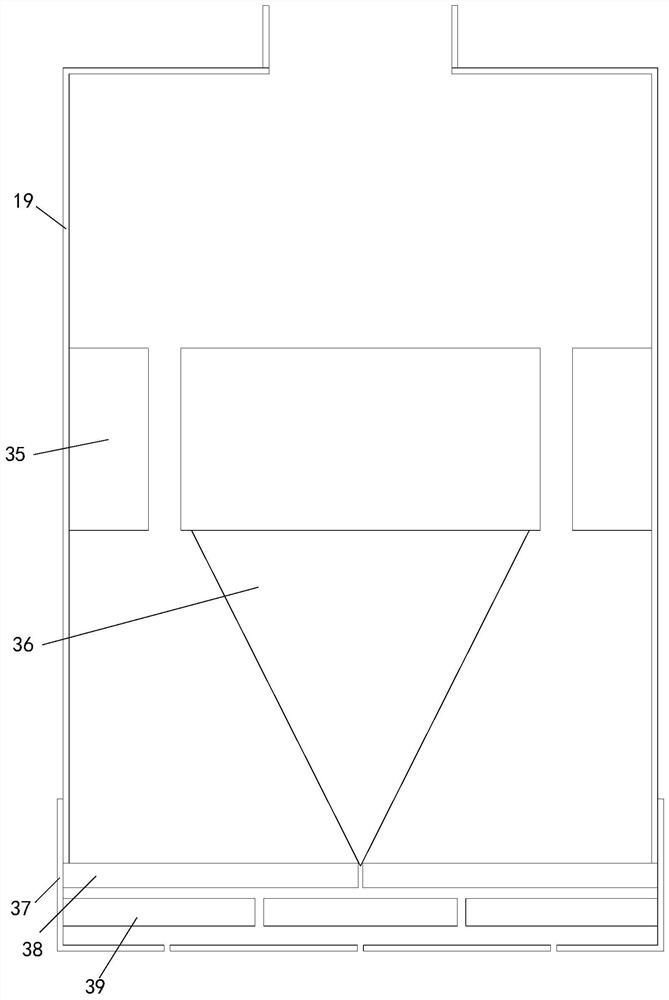

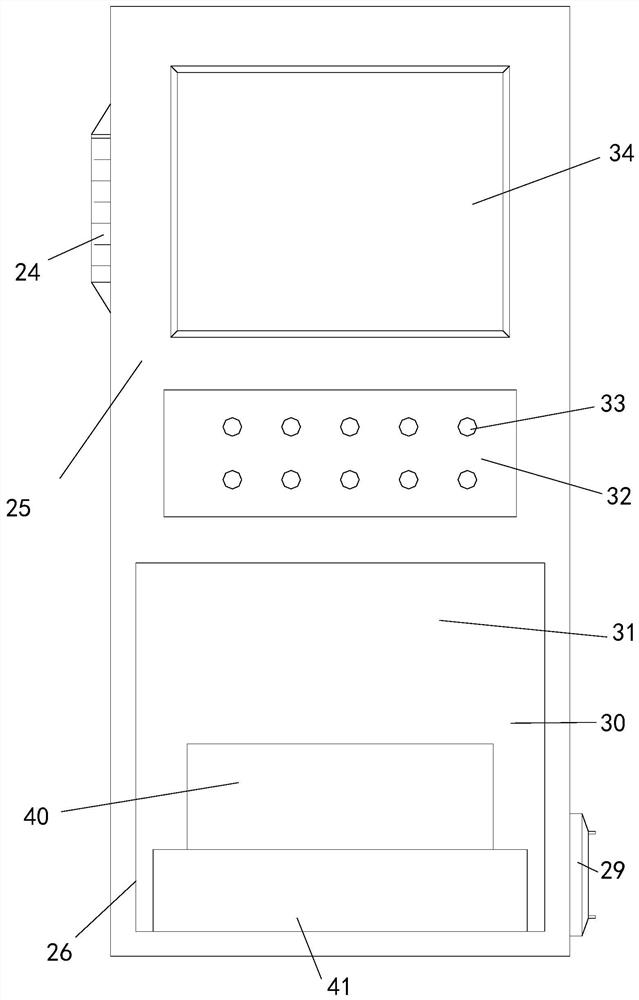

[0029] see Figure 1-5, the present invention provides a technical solution: a plant dust treatment device and its treatment method, including a workshop body 1, a processing part and a control part, characterized in that a first round hole is opened in the upper left end of the workshop body 1, and A ventilation window 23 is arranged in the first round hole, and a water tank 21 is arranged on the top of the workshop body 1, and the pure water 22 is filled in the water tank 21. The bottom end of the shower head 19 is provided with a plurality of shower heads 19, the inside of the shower head 19 is provided with a first chamber, and the inner sidewall of the first chamber is provided with a first refinement net 35, and the bottom end of the first refinement net 35 is provided with a Cone body 36, the bottom end of vertebral body 36 is provided with the second refinement net 38, the bottom end of the second refinement net 38 is provided with the 3rd refinement net 39, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com