Process and equipment for purifying waste water containing organic pollutants by continuous homogenization and optical oxidization

A technology of organic pollutants and photo-oxidation, which is applied in oxidation water/sewage treatment, illumination water/sewage treatment, energy and waste water treatment, etc. It can solve the problem of inconvenient separation and recovery of catalysts, inconvenient continuous industrial operation, and large reactor area. and other problems, to achieve the effect of small footprint, low cost and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

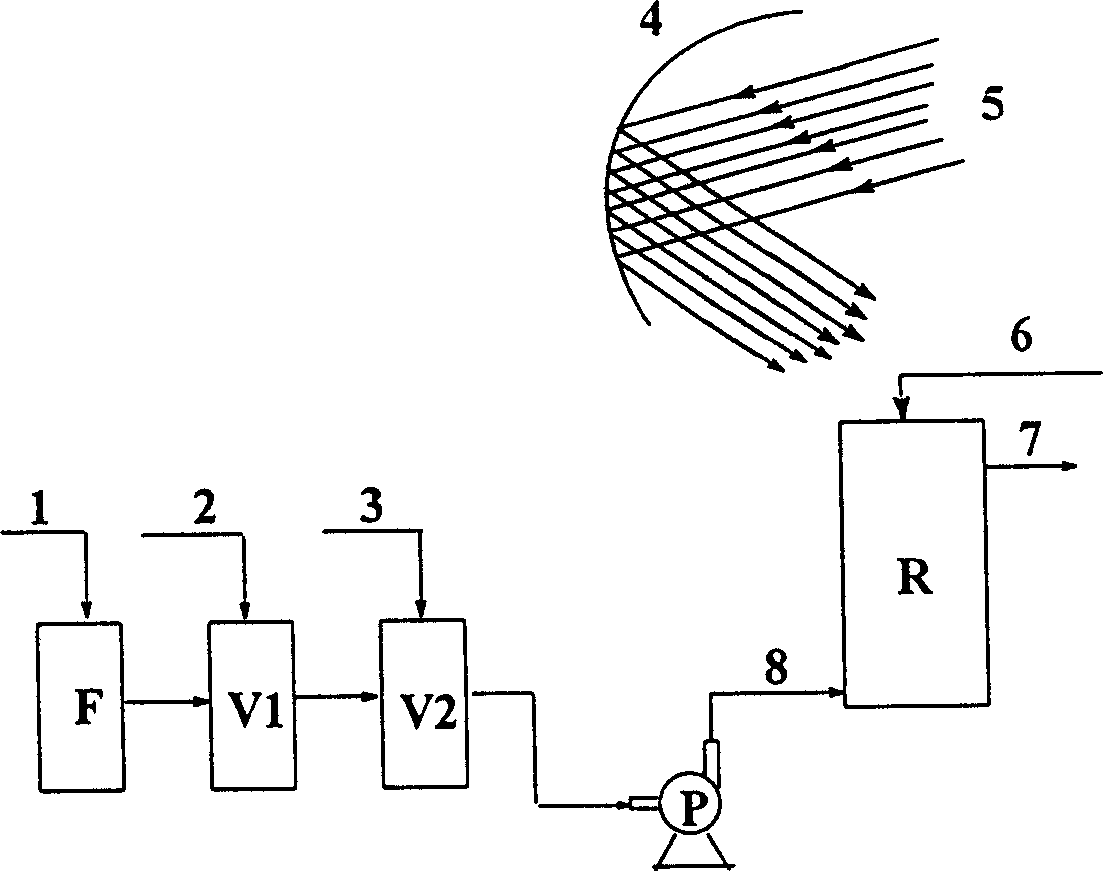

[0050] The method for continuous homogeneous photooxidative purification of waste water containing organic pollutants of the present invention is as follows:

[0051] Under normal temperature and pressure, the water to be treated is pre-filtered by the filter F to remove suspended solids, and the filtrate flows into the regulator V1, and the pH value of the water to be treated is adjusted to 2-3 by acid or alkali 2; from the regulator V1 The water to be treated enters the mixer V2 and the photocatalyst and hydrogen peroxide 3 that enter from the upper part of the mixer V2 are based on the weight of the photocatalyst: the weight of the water to be treated=10 -7 : 1~10 -2 : 1 and hydrogen peroxide weight: water weight to be treated=10 -6 : 1~10 -1 : 1 ratio mixing. After mixing, the water to be treated containing photocatalyst and hydrogen peroxide enters the combined photoreactor R from the feed port 8 at the lower left side of the combined photoreactor R through the deliver...

Embodiment 2

[0054] The device used in the method for continuous homogeneous photocatalytic purification of wastewater containing organic pollutants of the present invention

[0055] prepare, such as figure 1 , figure 2 shown, including

[0056] A filter F is a general filter device;

[0057] A regulator V1, for the general storage tank;

[0058] a mixer V2, which is equipped with a mechanical stirring device;

[0059] A transfer pump P, which transfers the material in the mixer to the combination photoreactor R.

[0060] The filter F, the regulator V1, the mixer V2, and the delivery pump P are connected by pipelines, and their positional relationship can ensure smooth fluid flow.

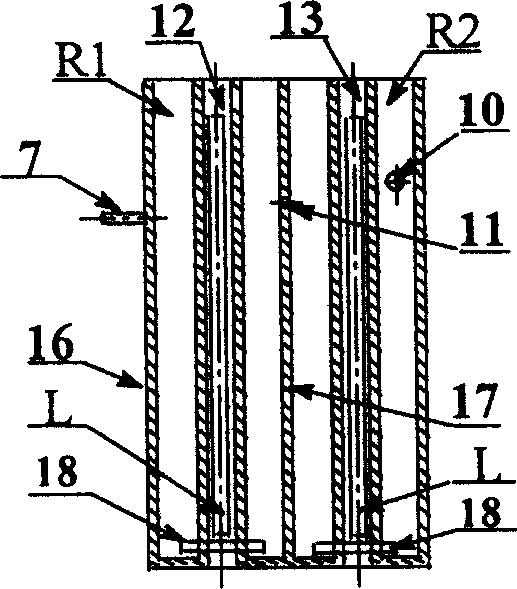

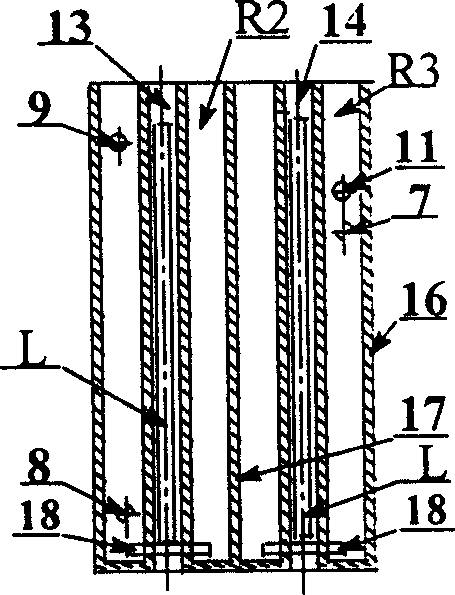

[0061] A combined photoreactor R is square in shape and upright, with a height / width ratio of 1:10 to 10:1. The combined photoreactor R is divided into four parts by the partition plate 17 to form four independent single photoreactors, respectively R1, R2, R3, R4. Each single photoreactor R1, R2, R3, R4 i...

Embodiment 3

[0070] The combined photocatalytic reactor (R) has a total volume of 30 liters and a square appearance. The interior is divided into four single reactors called R1, R2, R3, and R4, and their effective volumes are 9, 8, 7, 6 liters. Wastewater containing acid red G dye was selected as the water to be treated. Which contains acid red G concentration of 10 -3 M, the chemical oxygen demand CODcr before degradation is 1900mg / L, and the total organic carbon TOC is 374.5mg / L. The water to be treated is pre-filtered by the filter (F) to remove larger suspended solids, the filtrate flows into the regulator (V1), and sulfuric acid is added to adjust the pH value of the water to be treated to 2.5; the to-be-treated water from the regulator (V1) The treated water enters the mixer (V2) and is mixed with the photocatalyst and hydrogen peroxide (3) entering from the upper part of the mixer (V2). -4 : 1, the weight ratio of hydrogen peroxide (weight percentage concentration is 30%) and was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com