A high-efficiency window-breaking hammer for new energy buses

A bus and new energy technology, applied in vehicle components, vehicle safety arrangements, pedestrian/occupant safety arrangements, etc., can solve the problem of difficulty in breaking windows, and achieve the effects of improving safety performance, improving adsorption force, and convenient and labor-saving use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

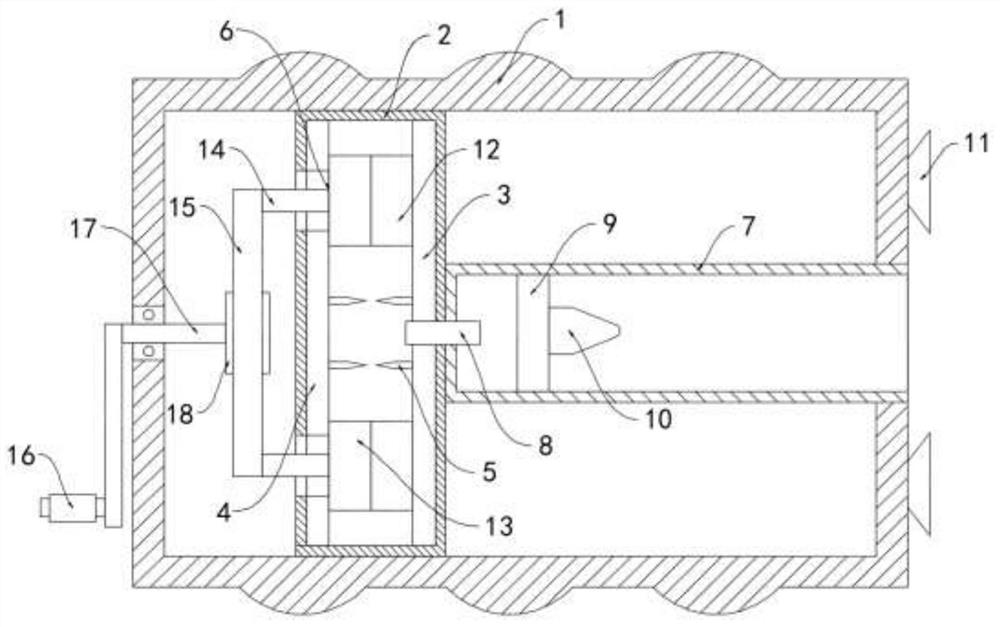

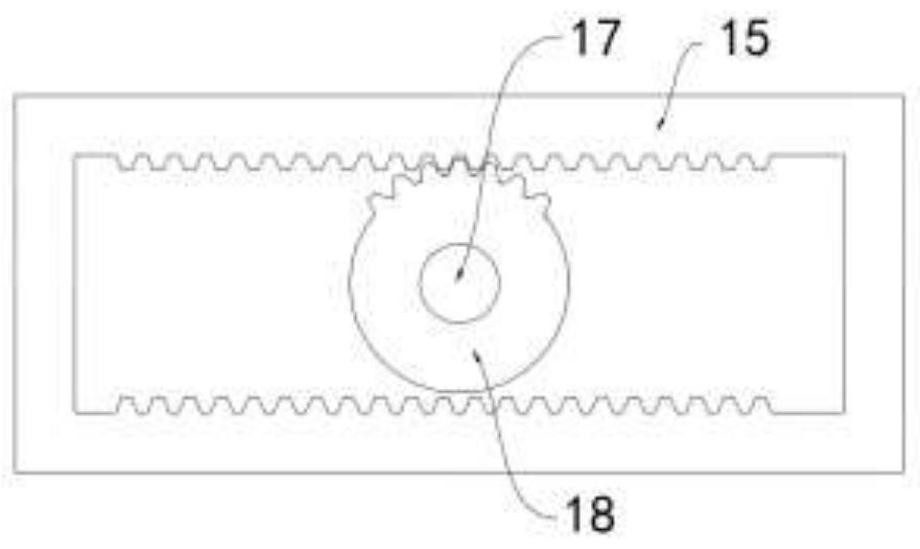

[0020] Such as Figure 1-2 As shown, a high-efficiency window breaking hammer for a new energy bus includes a housing 1, a plurality of suction cups 11 are installed on the side wall of the housing 1, an insulating cylinder 2 is fixedly installed in the housing 1, and the insulating cylinder 2 is filled with There is a mixed gas of methane and air, and the side walls on both sides of the insulating cylinder 2 are respectively fixedly connected with the first induction plate 3 and the second induction plate 4, and the discharge needle 5 is installed on the first induction plate 3 and the second induction plate 4 , a plurality of discharge needles 5 facing each other in pairs and not touching each other, an electrostatic generating mechanism 6 is provided on the insulating cylinder 2, a sliding cylinder 7 is fixedly connected to the side wall of the insulating cylinder 2, and the other end of the sliding cylinder 7 runs through the housing 1 The side wall of the sliding cylinder...

Embodiment 2

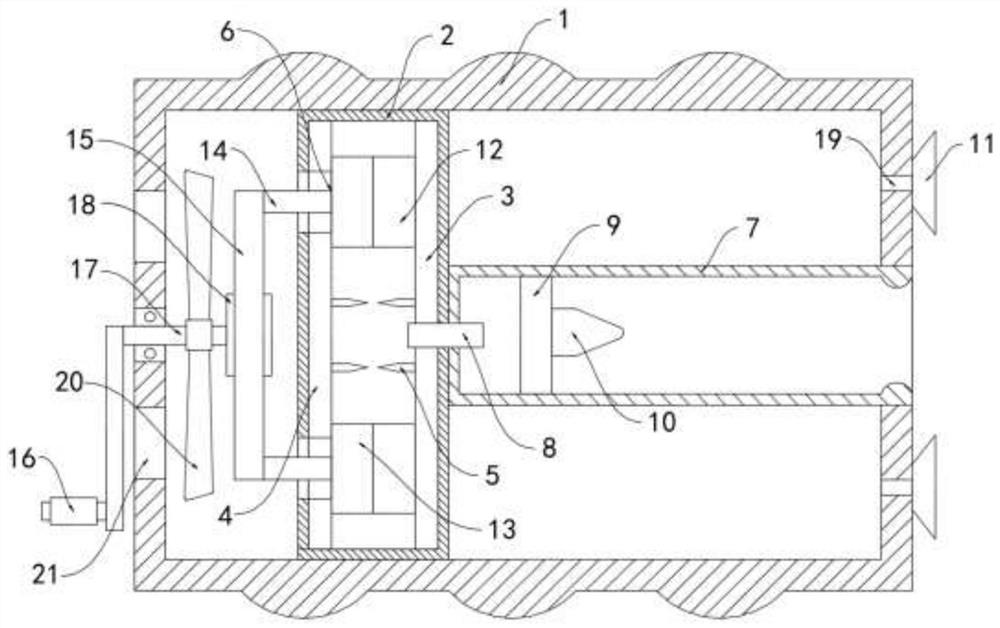

[0024] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the suction cup 11 communicates with the inside of the housing 1 through the one-way communication pipe 19, and the fan 20 is coaxially fixedly sleeved outside the rotating shaft 17, and the housing 1 is close to the fan 20 to blow air. Vent holes 21 are opened on the side wall of the surface.

[0025] In this embodiment, the fan 20 can rotate synchronously with the rotating shaft 17, and discharge the air in the casing 1 through the exhaust hole 21, so that a negative pressure is formed in the casing 1 and the suction cup 11, and the adsorption between the suction cup 11 and the surface of the glass to be broken is improved. to further enhance its safety performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com