Graphene heating fabric and preparation method thereof

A heating fabric, graphene technology, applied in the direction of electric heating devices, ohmic resistance heating, textiles and papermaking, etc., to achieve good heating effect, broad market prospects, and good heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

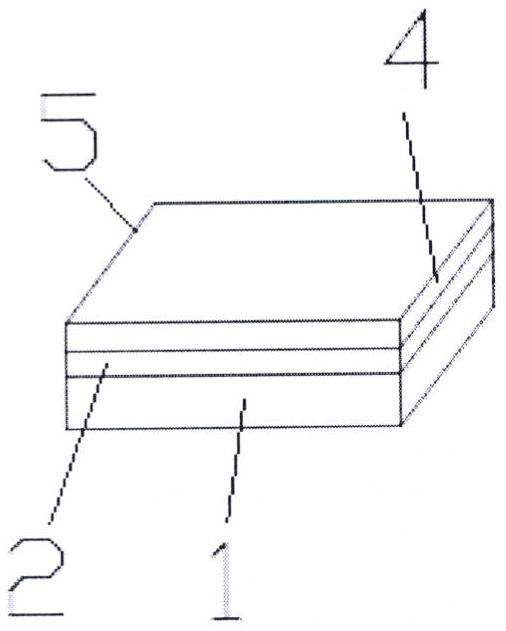

[0028] see Figure 2-3 , a graphene heating fabric, comprising: a substrate, a conductive graphene ink layer arranged on the substrate and a copper foil wire, and an insulating adhesive layer coated on the surface of the conductive graphene ink layer, the substrate is An insulating film with a thickness of 30 microns, and the conductive graphene ink layer is composed of graphene and conductive ink according to a mass ratio of 13:1.

[0029] Further, in this embodiment, the insulating glue is a kind of composite glue with good electrical insulation performance, which can be used for pouring cable joints, impregnating motors, electrical appliances, generator windings, and making transformers, capacitors or radio devices, etc. Sealing and insulation can be existing products, such as insulating glue such as polyester, epoxy, polyurethane, polybutadiene acid, silicone, polyesterimide and polyimide, which can be selected according to the specific needs, and are not specified here. ...

Embodiment 2

[0034] see Figure 2-3 , a graphene heating fabric, comprising: a substrate, a conductive graphene ink layer arranged on the substrate and a copper foil wire, and an insulating adhesive layer coated on the surface of the conductive graphene ink layer, the substrate is An insulating film with a thickness of 200 microns, and the conductive graphene ink layer is composed of graphene and conductive ink in a mass ratio of 19:1.

[0035] Further, in this embodiment, the insulating glue is a kind of composite glue with good electrical insulation performance, which can be used for pouring cable joints, impregnating motors, electrical appliances, generator windings, and making transformers, capacitors or radio devices, etc. Sealing and insulation can be existing products, such as insulating glue such as polyester, epoxy, polyurethane, polybutadiene acid, silicone, polyesterimide and polyimide, which can be selected according to the specific needs, and are not specified here. limited. ...

Embodiment 3

[0039] see Figure 1-3 , a preparation method of graphene heating fabric, the steps are as follows:

[0040] 1) Weigh graphene and conductive ink according to the ratio of 13-19:1 by mass and stir and mix them evenly to obtain conductive graphene slurry;

[0041] 2) Coating the conductive graphene slurry obtained in the copper foil wire and step 1) on the substrate at the same time, and drying at a temperature of 150° C. to obtain a substrate provided with a conductive graphene ink layer and a copper foil wire ;

[0042] 3) the base material provided with the conductive graphene ink layer and the copper foil wire obtained in step 2) is cooled to room temperature, then coated with insulating glue on the surface of the conductive graphene ink layer and dried to form an insulating glue layer, to obtain final product Graphene heating fabric.

[0043] Further, the use voltage of the graphene heating fabric is 5V-36V, so as to improve the safety performance of the graphene heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com