Semi-flexible component carrier and manufacturing method thereof

A component-carrying, semi-flexible technology, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, circuit bendable/stretchable components, etc., can solve problems such as easy damage, to overcome significant defects, The effect of reducing the bend radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

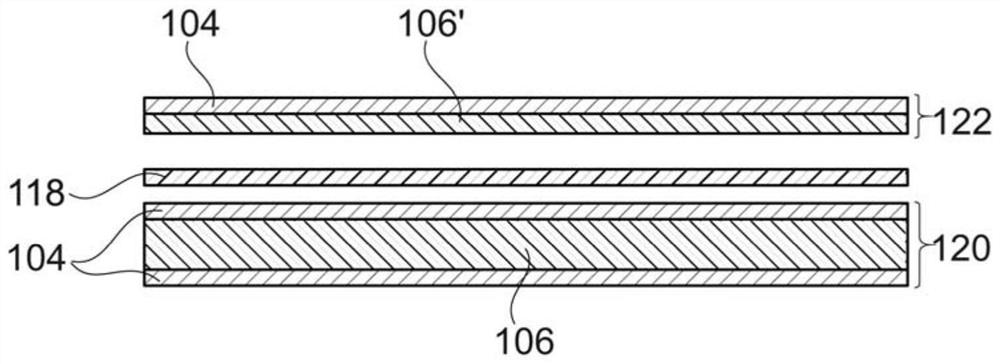

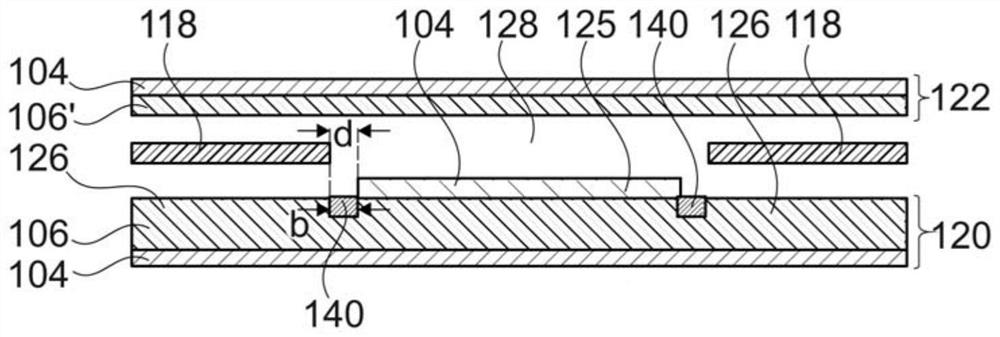

[0064]According to an exemplary embodiment of the present invention, a dielectric low modulus and high elongation material can be applied to a semi-flexible part of a semi-flexible component carrier (especially a printed circuit board, PCB). This can allow small bending radii to be resolved and dynamic bending angles can be achieved on semi-flexible component carriers. In particular, this can be achieved by arranging a dielectric material in at least the semi-flexible part so as to have a low Young's modulus lower than 5 GPa and a high elongation higher than 3%. Therefore, the dielectric material in the semi-flexible portion can be elastic and malleable.

[0065]According to an exemplary embodiment of the present invention, a semi-flexible PCB is provided with a semi-flexible portion of a dielectric material, which has a low Young's modulus lower than 5 GPa and a high elongation higher than 3%. Traditionally, PCBs are only used for high bend radius applications with estimated radii gre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com