Layered sampling device for concrete production

A sampling device and concrete technology, which is applied in the direction of sampling devices, etc., can solve the problems of not being able to meet the needs of use well, the sampling device is inconvenient to clean, and the concrete cannot be sampled, etc., so as to achieve easy access to samples, convenient cleaning, and refinement of sampling depth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

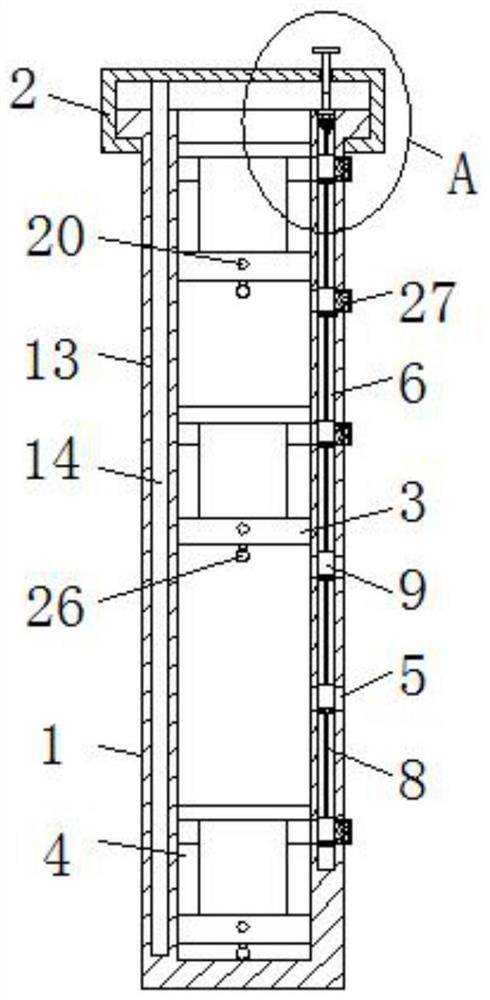

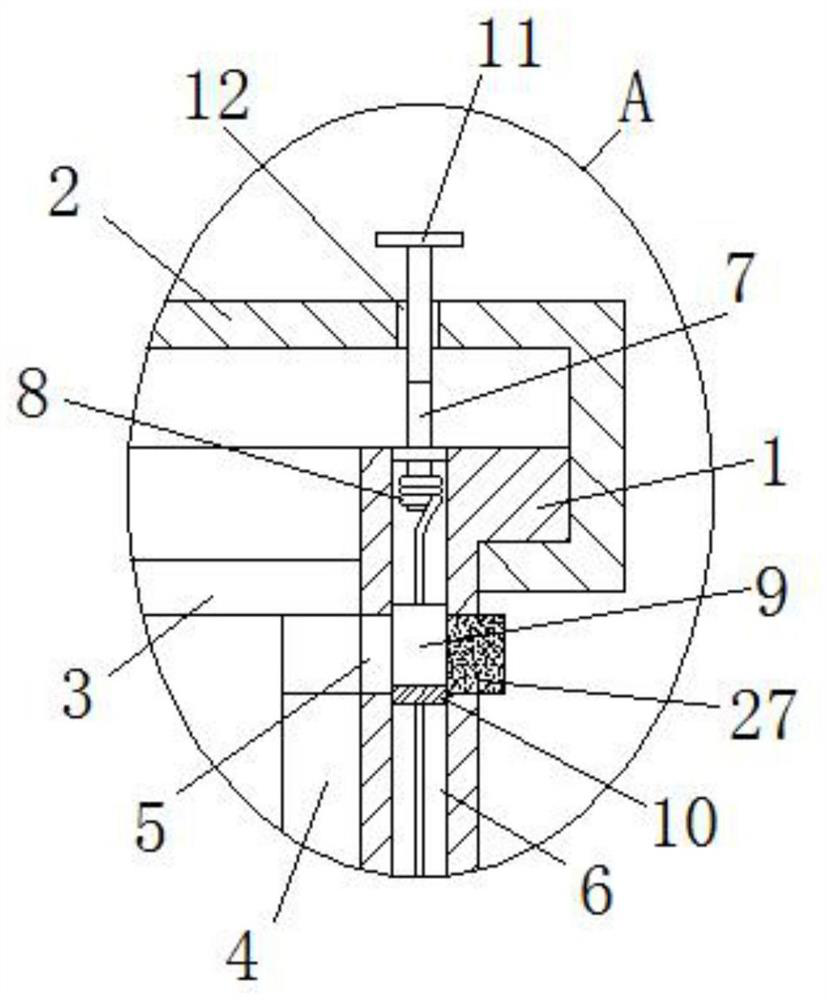

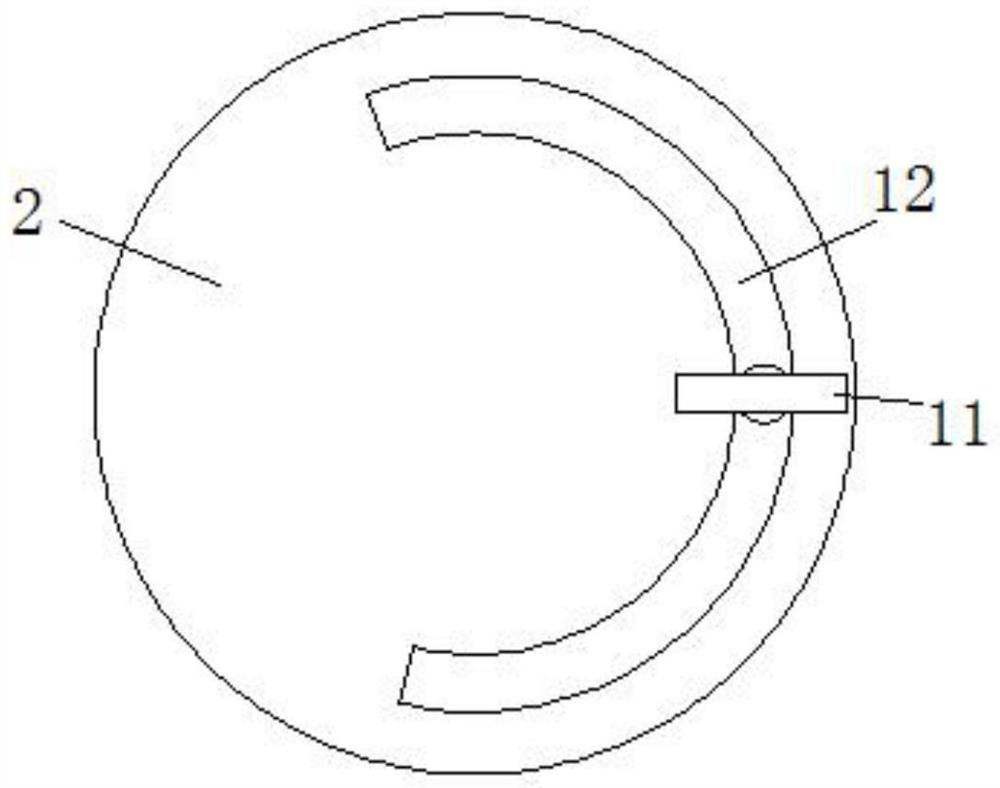

[0025] refer to Figure 1-5 , a sampling device for layered concrete production, comprising a sampling cylinder 1, the rear side of the inner wall of the sampling cylinder 1 is provided with a second cavity 13, and the inside of the second cavity 13 is movably connected with an arc-shaped partition 14, the arc-shaped The upper end of the partition 14 is fixedly connected to the cylinder cover 2, and the front side of the inner wall of the sampling cylinder 1 is provided with a slot 15 that is compatible with the arc-shaped partition 14, and the inner wall of the slot 15 is fixedly bonded with a first magnetic strip 16. The front end of the arc-shaped partition 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com