Die-pressing cap making machine and cap making die thereof

A mold and bottle cap technology, applied in other household appliances, household appliances, household components, etc., can solve the problems of poor cooling effect, shortened life of parts, weakened strength of parts, etc., to shorten the cooling and setting time, improve efficiency and quality , the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

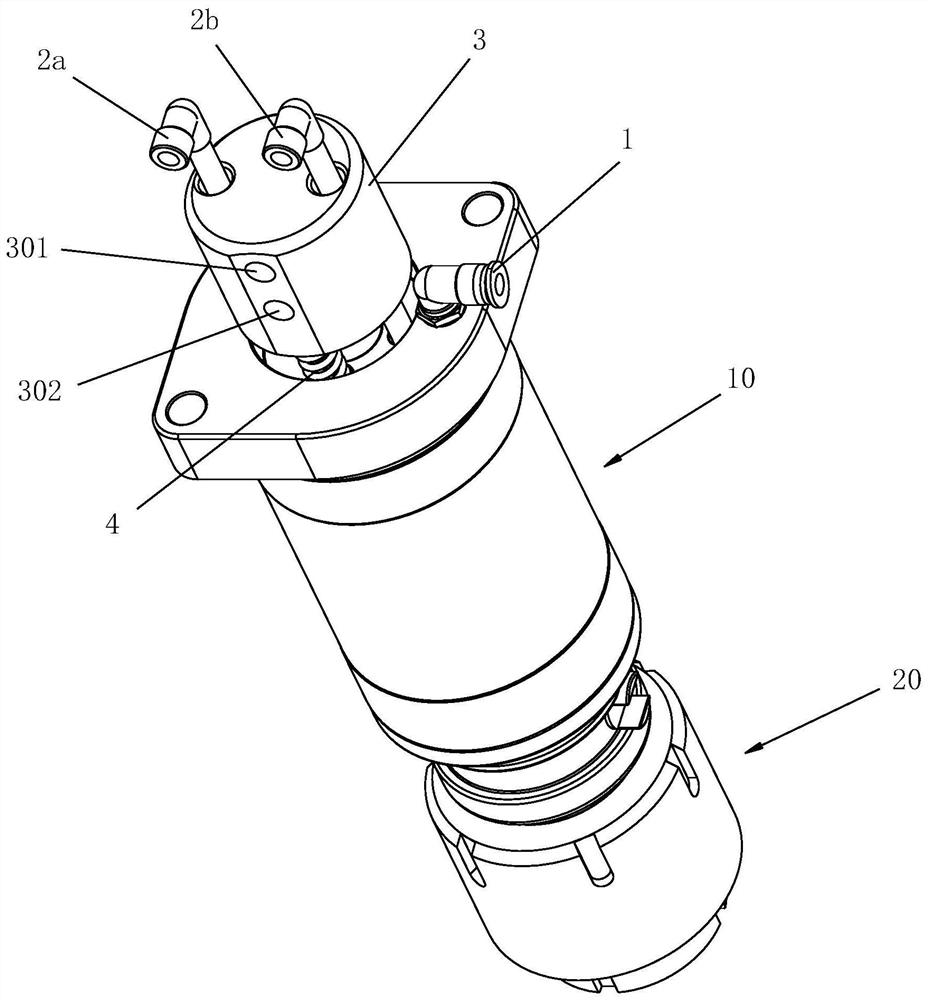

[0029] See attached figure 2 and Figure 5 , a cap making mold provided in this embodiment is used for the preparation of a bottle cap 30. The bottle cap 30 includes an inner side and an outer side opposite to the inner side, and the inner side includes a bottom and surrounding the bottom. A threaded side wall formed in its circumferential direction, the cap making mold includes: a patrix 10 and a lower die 20, an upper mold surface of the upper mold 10 and a lower mold surface of the lower mold 20 cooperate to form a A mold cavity (not shown) for forming the bottle cap 30 is formed.

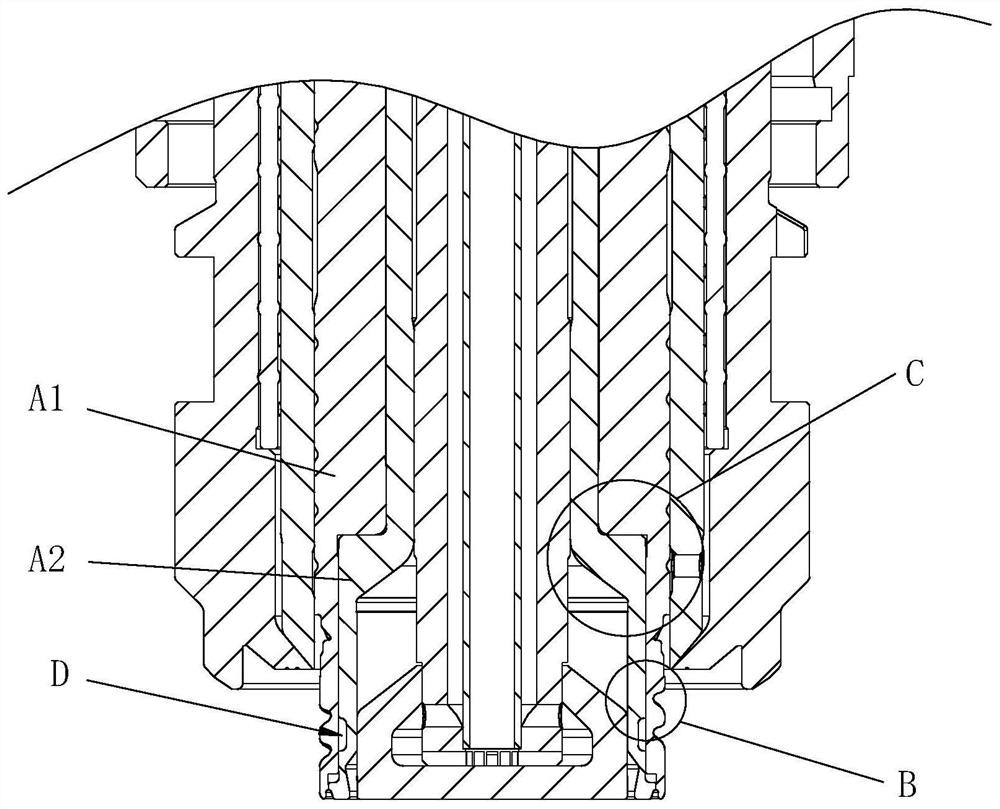

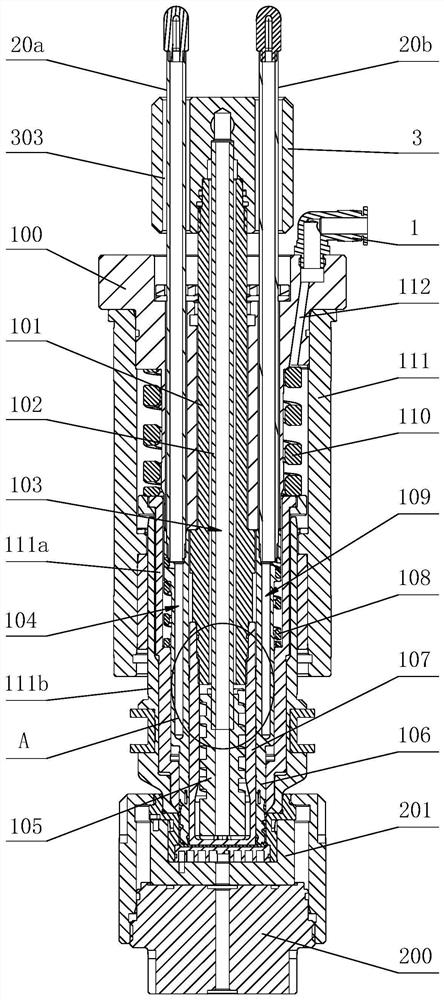

[0030] refer to figure 2 , image 3 , Figure 4 , Figure 5 as well as Image 6 , the upper mold 10 includes an upper mold body, a cooling module and an ejection module. Wherein, the body of the upper mold 10 includes a cylindrical sleeve 111 and a fixed installation part 100, and the fixed installation part 100 is installed on the upper end of the cylindrical sleeve and extends into th...

Embodiment 2

[0040] This embodiment provides a molding and capping machine, comprising a frame (not shown), a feed module (not shown) and an extrusion die set on the frame (not shown). group (not shown) and a pressing module (not shown), the pressing module includes a rotating main body and a predetermined number of compression molds arranged on the rotating main body, the compression molding mold is an embodiment The lid making mold provided in 1. The feed module extrudes the prepared raw materials from the extrusion module to the compression module, and the extrusion module is extruded to the compression module and then manufactured by the cap making mold. cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com