Self-cleaning type tissue cutting method for hygienic products

A cutting method and technology of sanitary products, applied in the field of sanitary products, can solve the problems of fiber drop, health hazards of workers, and not very firm combination, and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

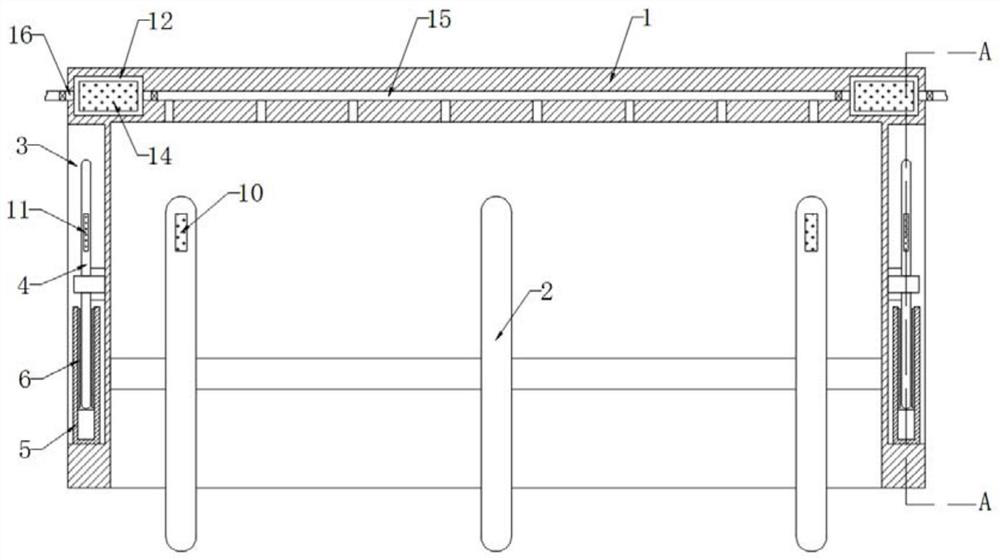

[0027] refer to Figure 1-2 , a self-cleaning paper towel cutting method for hygiene products, comprising the following steps;

[0028] S1, rewinding, put the large shaft paper on the toilet paper rewinding machine for rewinding processing, so that the paper towel is rolled into a long strip of roll paper;

[0029] S2, installation, for the required cutting width of the paper towel, adjust the distance between the cutting knives 2 on the cutting machine, and then install the long roll paper on the cutting machine;

[0030] S3, cutting, start the cutting machine, so that the cutting knife 2 cuts the long roll paper;

[0031] S4. Packing. Put the cut paper towels in the packaging bag, vacuum the inside of the packaging bag, and seal the packaging bag.

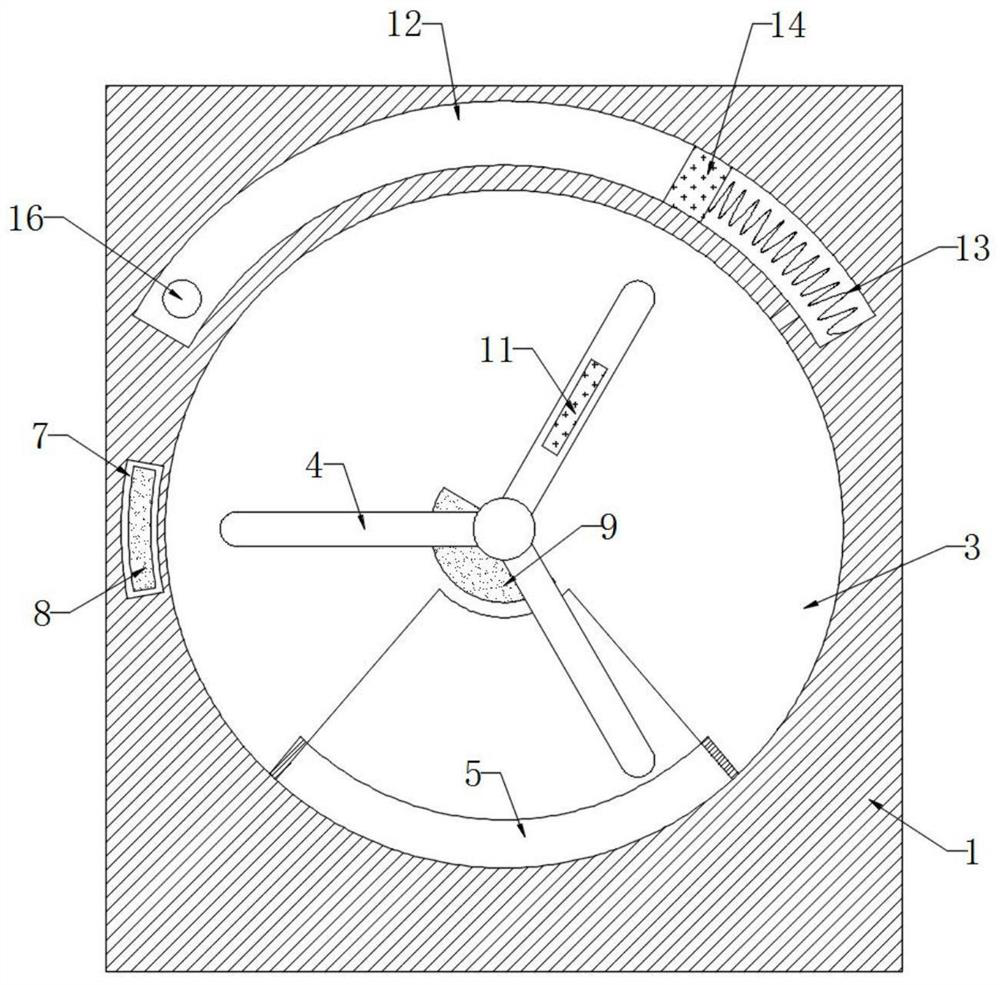

[0032] In the process of the above paper towel cutting method, a paper towel cutting device is also involved, including a frame 1, a plurality of cutting knives 2 are connected to the inner wall of the frame 1 through a rotatin...

Embodiment 2

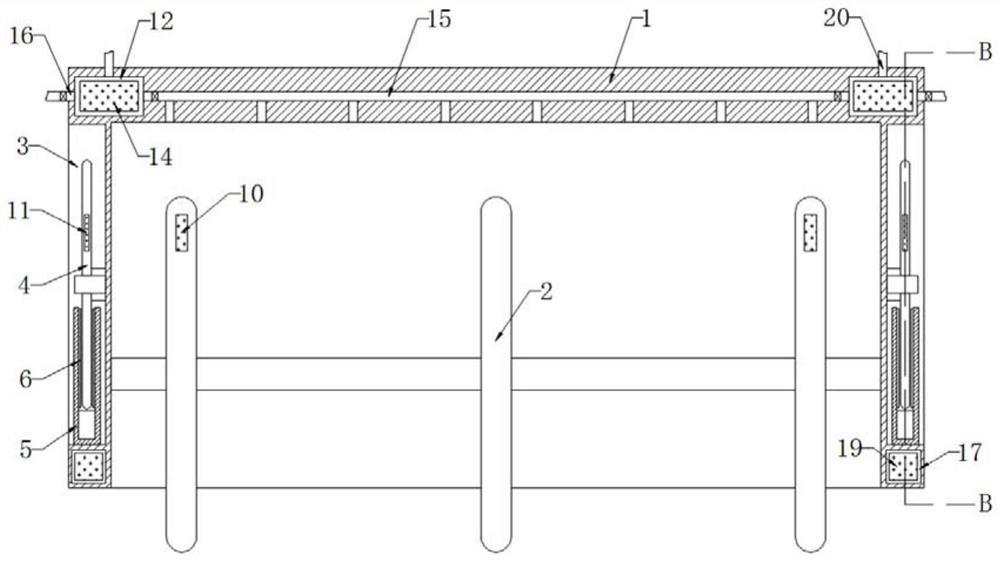

[0038] refer to Figure 3-4 , different from Embodiment 1, the lower end of the circular groove 3 is provided with a second arc-shaped cavity 17, and the inner wall of the second arc-shaped cavity 17 is elastically connected with a magnetic slider 19 through a return spring 18, and the magnetic slider 19 is connected to the second arc-shaped cavity. The inner wall of the cavity 17 is sealed and slidingly connected, and the inner wall of the second arc-shaped cavity 17 away from the return spring 18 is connected to the top of the first arc-shaped cavity 12 through the one-way outlet pipe 20, and the inner wall of the second arc-shaped cavity 17 is far away from the return spring 18. One-way water suction pipe 21. It should be noted that the one-way water outlet pipe 20 only allows water to enter the first arc-shaped cavity 12 from the second arc-shaped cavity 17, and the one-way water suction pipe 21 only allows water to enter the second arc-shaped cavity from the outside. cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com