Concrete mixing plant with dust removal function and dust removal method thereof

A technology for concrete and mixing plants, which is applied to concrete mixing plants with dust removal function and the field of dust removal. It can solve the problems of affecting mixing efficiency, lowering material delivery efficiency, and caking, etc., and achieves improved use efficiency, convenient replacement, and convenient cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present application will be described in further detail below in conjunction with accompanying drawings X-X.

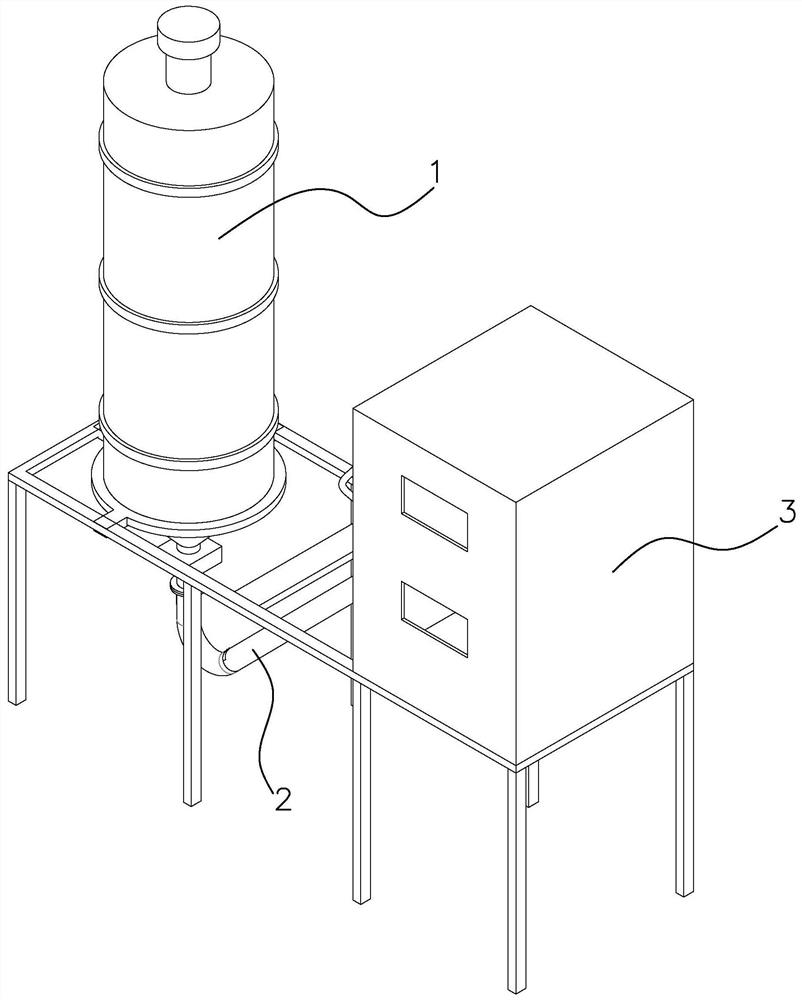

[0045] The embodiment of this application discloses a concrete mixing plant with dust removal function, referring to figure 1 and figure 2 , including a storage tank 1, the bottom of the storage tank 1 is fixedly connected with a feeding pipe 2, and the end of the feeding pipe 2 away from the storage tank 1 is fixedly connected with a stirring mechanism 3. When in use, raw materials can be added to the stirring mechanism 3 through the feeding pipe 2 after the raw materials are stored in the storage tank 1 .

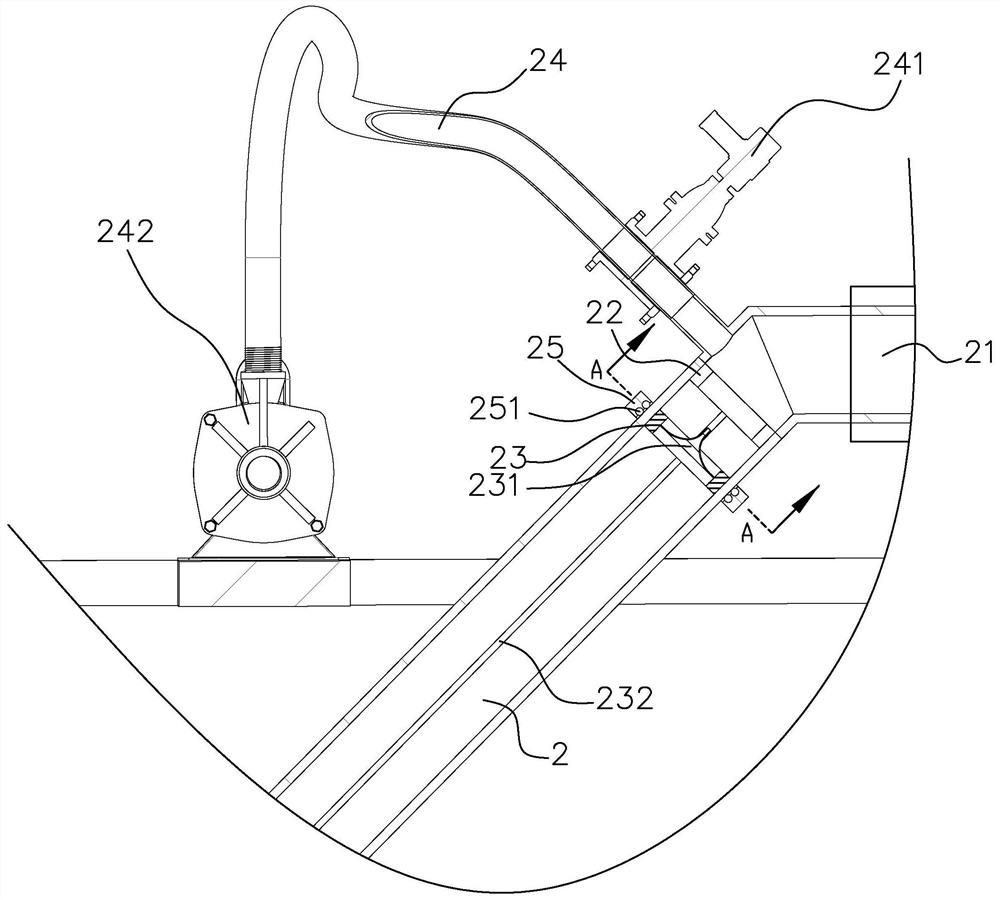

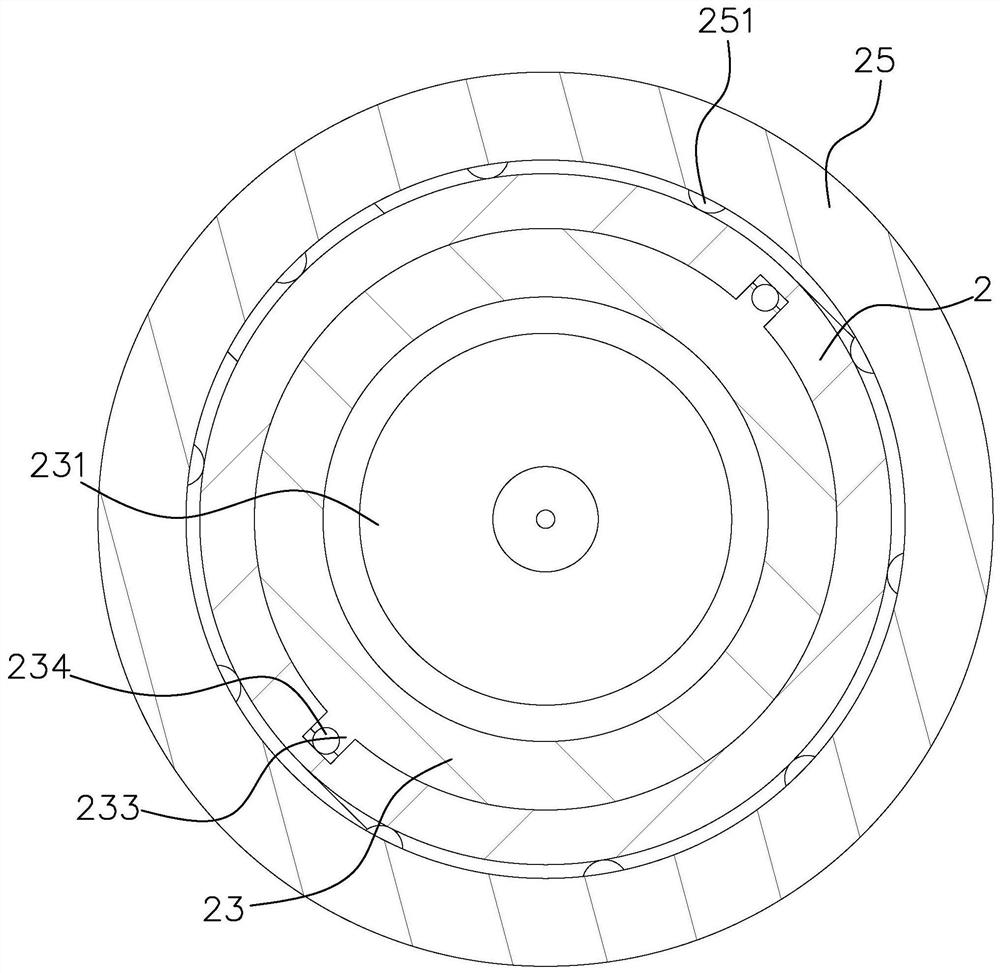

[0046] refer to figure 2 and image 3The end of the feeding pipe 2 close to the stirring mechanism 3 is provided with a main valve 21 for closing the feeding pipe 2 . A cleaning ring 23 whose outer diameter is equal to the inner diameter of the feeding pipe 2 is slidably connected in the feeding pipe 2 , and the cleaning ring 23 slides along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com