Pulse filtration blowback system for gas turbine

A pulse and gas turbine technology, applied in the direction of dispersed particle filtration, separation method, dispersed particle separation, etc., can solve the problems such as poor cleaning effect of the filter element, achieve the effect of improving the cleaning effect, increasing the contact area, and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

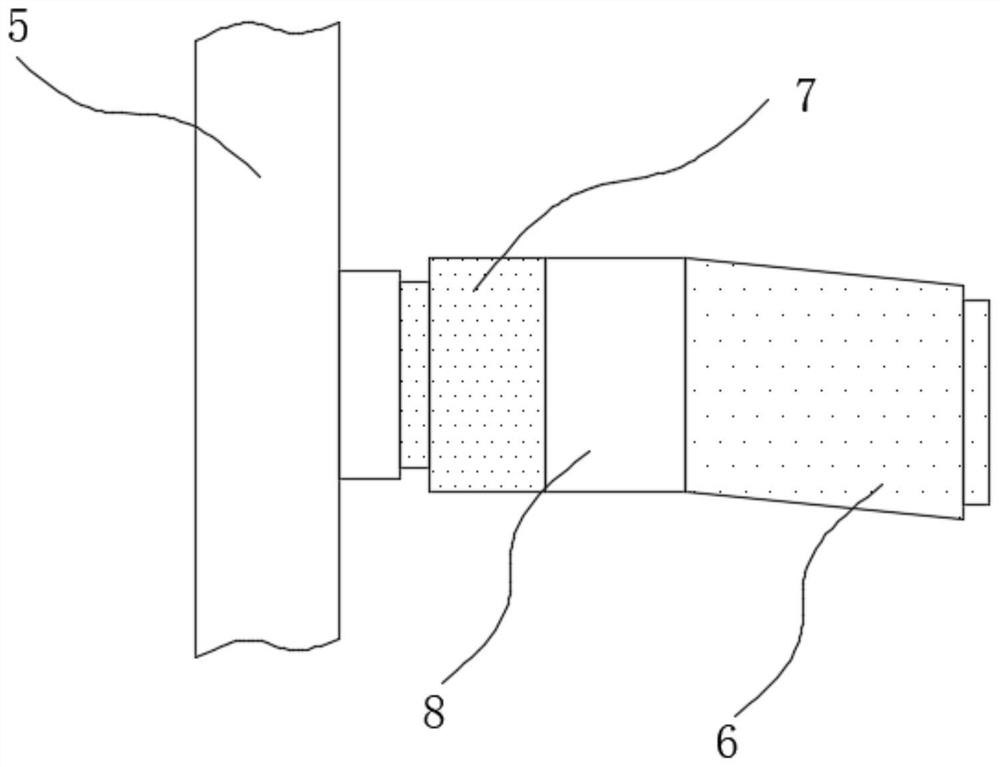

[0028] see Figure 1-Figure 5, this embodiment provides a pulse filter blowback system for gas turbines, including a rainproof shed 1, a tube plate 2 is installed inside the rain proof shed 1 and close to the air outlet, and the tube plate 2 is far away from the outlet of the rain proof shed 1 The filter element holder 3 is bolted to the side, and the filter element holder 3 is arranged in an array. There is a circular large hole inside the tube plate 2 and at the filter element support 3, which is a channel for filtered clean air. The filtered clean air is separated from the dirty air before filtration. The filter element holder 3 is fixed with a filter element 4. The inside of the rainproof shed 1 and below the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com