Preparation method of filter material with formaldehyde removal function

A formaldehyde removal and filter material technology, applied in the field of functional filter material preparation, can solve the problems that formaldehyde molecules cannot be removed, bacteria are introduced, and the air purification quality is affected, so as to achieve a good removal effect, increase acidity, and reduce the effect of glossy appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

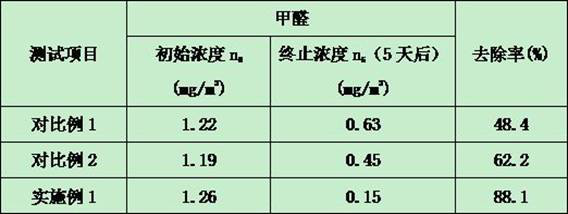

Examples

Embodiment 1

[0017] Follow the steps below to prepare a filter material with formaldehyde removal function:

[0018] 1) Preparation of filter material treatment agent: firstly weigh and mix the following raw materials in parts by mass to prepare a powder: 40 parts of water-soluble hydroxycellulose, 20 parts of blueberry leaf polyphenols, 8 parts of sodium alginate, and 6 parts of sodium citrate , 30 parts of polyvinyl acetate, 0.5 parts of sodium dodecyl sulfonate, 50 parts of nano-alumina;

[0019] Then weigh and mix the following raw materials in parts by mass to prepare a liquid preparation: 20 parts of acetic acid, 10 parts of ethanol, 50 parts of nano-silica colloid, and 5 parts of distilled water; mix the powder and liquid preparation at a mass ratio of 10:1 Stirring is configured as a filter material treatment agent;

[0020] 2) Preparation of formaldehyde photocatalytic decomposing agent: Weigh the following raw materials in parts by mass and mix them to prepare formaldehyde photo...

Embodiment 2

[0023] Follow the steps below to prepare a filter material with formaldehyde removal function:

[0024] 1) Preparation of filter material treatment agent: First, weigh the following raw materials in parts by mass and mix them to prepare a powder: 30 parts of water-soluble hydroxycellulose, 20 parts of blueberry leaf polyphenols, 8 parts of sodium alginate, and 3 parts of sodium citrate , 15 parts of polyvinyl acetate, 0.5 part of sodium dodecyl sulfonate, 50 parts of nano-alumina;

[0025] Then weigh and mix the following raw materials in parts by mass to prepare a liquid preparation: 20 parts of acetic acid, 10 parts of ethanol, 30 parts of nano-silica colloid, and 3 parts of distilled water; mix the powder and liquid preparation at a mass ratio of 3:1 Stirring is configured as a filter material treatment agent;

[0026] 2) Preparation of formaldehyde photocatalytic decomposing agent: Weigh the following raw materials in parts by mass and mix them to prepare formaldehyde pho...

Embodiment 3

[0029] Follow the steps below to prepare a filter material with formaldehyde removal function:

[0030] 1) Preparation of filter material treatment agent: First, weigh the following raw materials in parts by mass and mix them to prepare a powder: 20 parts of water-soluble hydroxycellulose, 15 parts of blueberry leaf polyphenols, 8 parts of sodium alginate, and 6 parts of sodium citrate , 15 parts of polyvinyl acetate, 0.5 part of sodium dodecyl sulfonate, 50 parts of nano-alumina;

[0031] Then the following raw materials were weighed and mixed in parts by mass to prepare a liquid preparation: 20 parts of acetic acid, 10 parts of ethanol, 30 parts of nano-silica colloid, and 5 parts of distilled water; the powder and the liquid preparation were mixed according to a mass ratio of 3:1 Stirring is configured as a filter material treatment agent;

[0032] 2) Preparation of formaldehyde photocatalytic decomposing agent: Weigh the following raw materials in parts by mass and mix th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com