Micro-current mask capable of improving essence absorptivity and preparation method of micro-current mask

A micro-current, absorption rate technology, applied in electrotherapy, skin care preparations, electrodes, etc., can solve problems such as poor effect, time and economic waste, and achieve the effect of promoting accelerated circulation and good skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

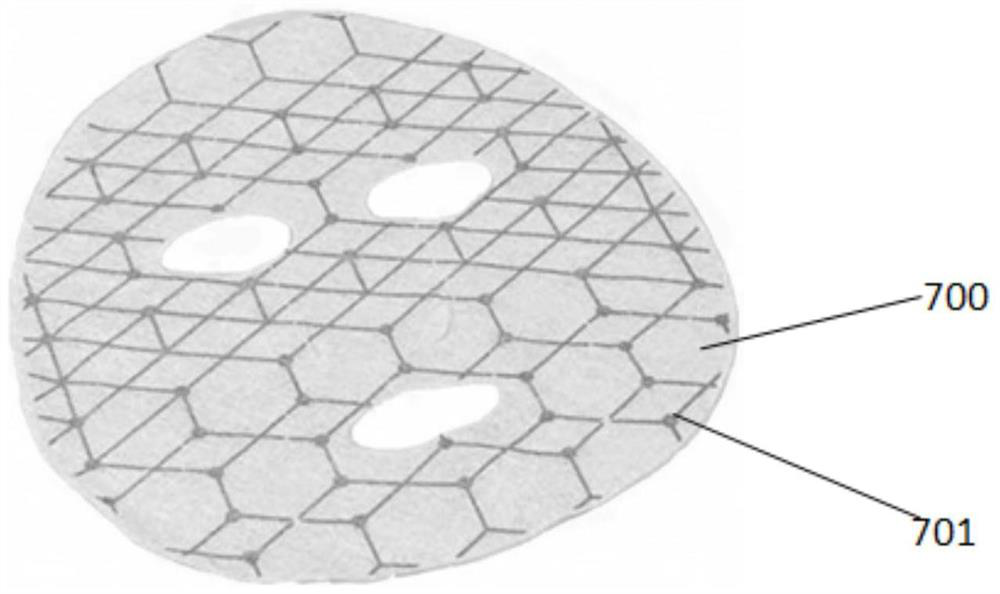

[0056] In order to solve the above-mentioned technical problems, the first aspect of the present embodiment provides a kind of preparation material of the micro-current facial mask that improves the absorption rate of essence, including conductive material, facial mask sheet 700 and essence, and described conductive material forms conductive mask on facial mask sheet. Pattern 701, the material of the mask sheet 700 is non-woven fabric, the front and back sides of the mask sheet 700 are all provided with the same conductive pattern 701, the upper and lower ends of the conductive pattern 701 are hexagonal patterns, from top to bottom The two ends are respectively provided with a quadrilateral pattern and a triangular pattern towards the middle. The mask has a triangular pattern around the eyes and around the nose. The inventor found that designing hexagonal patterns, quadrangular patterns and triangular patterns can not only conduct electricity, but also improve the bonding forc...

Embodiment 2

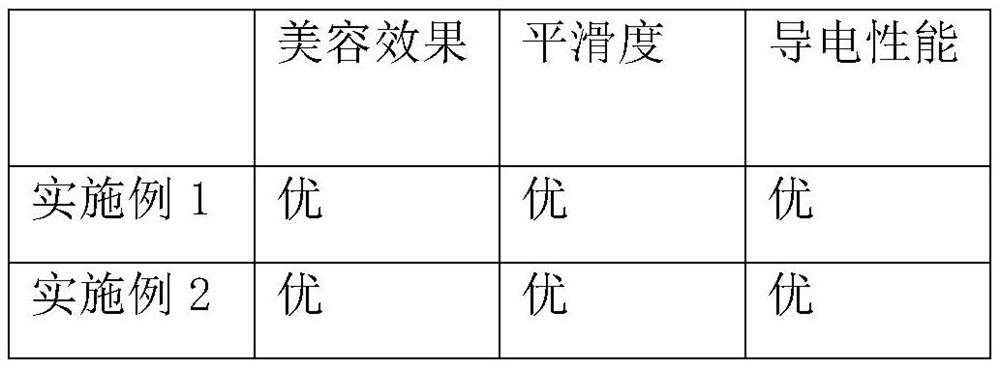

[0069] The difference between this embodiment and Example 1 is that the raw materials for the preparation of the silver paste material in this embodiment include 10 parts of silver powder, 60 parts of water-based resin, 2 parts of compatibilizer and 1 part of crosslinking agent in parts by weight. The silver powder is a mixture of flaky silver powder and spherical silver powder. The mass ratio of the flaky silver powder to the spherical silver powder is 5: 1. The length of the flaky silver powder is 5-8 μm. company, article number B116, and the particle size of the spherical silver powder is 80nm, purchased from Xuzhou Jie Innovation Material Technology Co., Ltd., article number A110. The mass ratio of the flake silver powder to the spherical silver powder is 5:2. Described water-based resin is the mixture of water-based polyurethane resin and water-based acrylic resin, and the mass ratio of described water-based polyurethane resin and water-based acrylic resin is 1:3.

[007...

Embodiment 3

[0080]The difference between this embodiment and Example 1 is that the raw materials for the preparation of the silver paste material in this embodiment include 10 parts of silver powder, 60 parts of water-based resin, 2 parts of compatibilizer and 1 part of crosslinking agent in parts by weight. The silver powder is a mixture of flaky silver powder and spherical silver powder. The mass ratio of the flaky silver powder to the spherical silver powder is 5: 2. The length of the flaky silver powder is 5-8 μm. company, article number B116, and the particle size of the spherical silver powder is 80nm, purchased from Xuzhou Jie Innovation Material Technology Co., Ltd., article number A110. Described water-based resin is the mixture of water-based polyurethane resin and water-based acrylic resin, and the mass ratio of described water-based polyurethane resin and water-based acrylic resin is 1:3.

[0081] The solid content of the water-based polyurethane resin is 29 ± 1%. The water-ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com