Composition of freeze-dried formulation, cosmetic kit for external use on skin including the same, and its use

A technology for skin external preparations and compositions, which is applied in the field of freeze-dried formulation compositions and skin external preparation cosmetic kits containing the same, can solve the problems of high-concentration use, slippery and sticky, etc., and achieves improved spreadability and small sticky feeling. , the effect of refreshing feeling of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069]

[0070]In an example, 20% by weight of sodium hyaluronate (sodium Hyaluronate) was dissolved in 0.25N NaOH, and then 0.1% by weight of BDDE was added, and crosslinking was performed at 37° C. for 24 hours. After cross-linking, the gel was neutralized with an equal amount of 0.25N HCl, and then fully washed with pure water to remove unreacted BDDE. The washed gel was pulverized into a size of 20 μm and 200 μm with a plunger mill. The gel content was quantified by dry content and carbazole analysis for hyaluronic acid.

[0071]

[0072] 5 g of cross-linked hyaluronic acid crushed to 20 μm, 10 g of low-molecular-weight hyaluronic acid with a molecular weight of about 3,000 Daltons, and 5 g of vitamin C were added to 980 g of purified water, and mixed with a homomixer. The mixture was poured into a mold and dried after being frozen to -20°C in a freeze dryer.

Embodiment 2

[0074] Add 5 g of cross-linked hyaluronic acid crushed to 200 μm prepared in Example 1, 10 g of low-molecular-weight hyaluronic acid with a molecular weight of about 3,000 Daltons, and 5 g of vitamin C into 980 g of purified water, and use a homogeneous mixer to to mix. The mixture was poured into a mold and dried after being frozen to -20°C in a freeze dryer.

experiment Embodiment 1

[0082] [Experimental Example 1] Characters

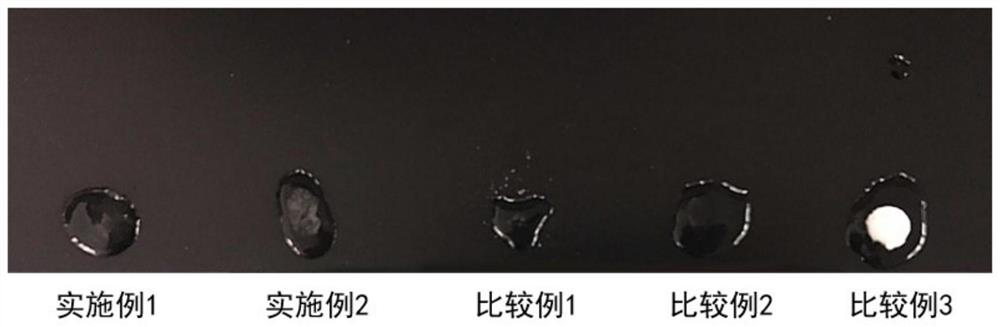

[0083] After freeze-drying, the results of confirming the properties of the dosage form, such as figure 1 As shown, the dosage forms of Example 1, Example 2, and Comparative Example 2 have a certain shape, but in the case of Comparative Example 1, there is a problem of fragmentation. From this, it was confirmed that the lyophilized dosage form cannot be maintained only with low-molecular-weight hyaluronic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com