Automatic retired part sequence image acquisition device

A sequential image and automatic collection technology, applied in the direction of image communication, color TV parts, TV system parts, etc., can solve the problems of immovability, low degree of automation, and small scope of application of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

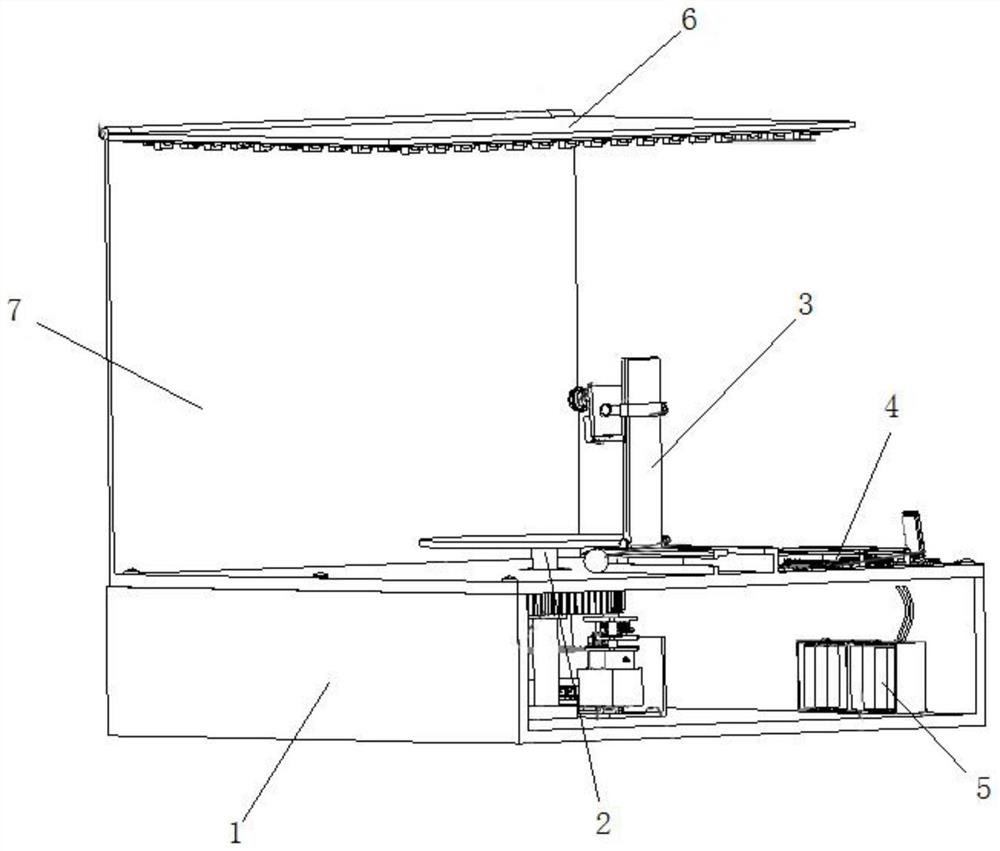

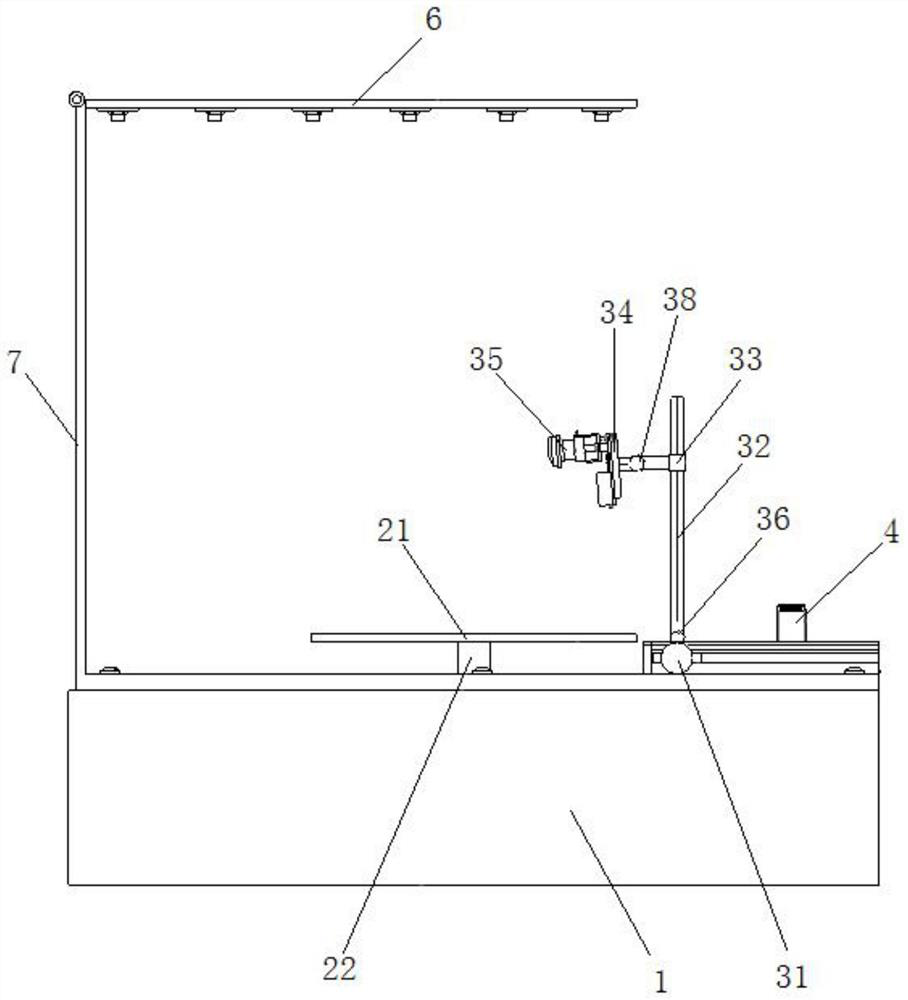

[0032] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , an automatic image acquisition device for decommissioned parts sequence provided by the embodiment of the present invention, such as figure 1 , figure 2 As shown, the device includes a base 1 for carrying various components; each component contained in the device can be installed on the upper part of the base 1 to facilitate mobile use.

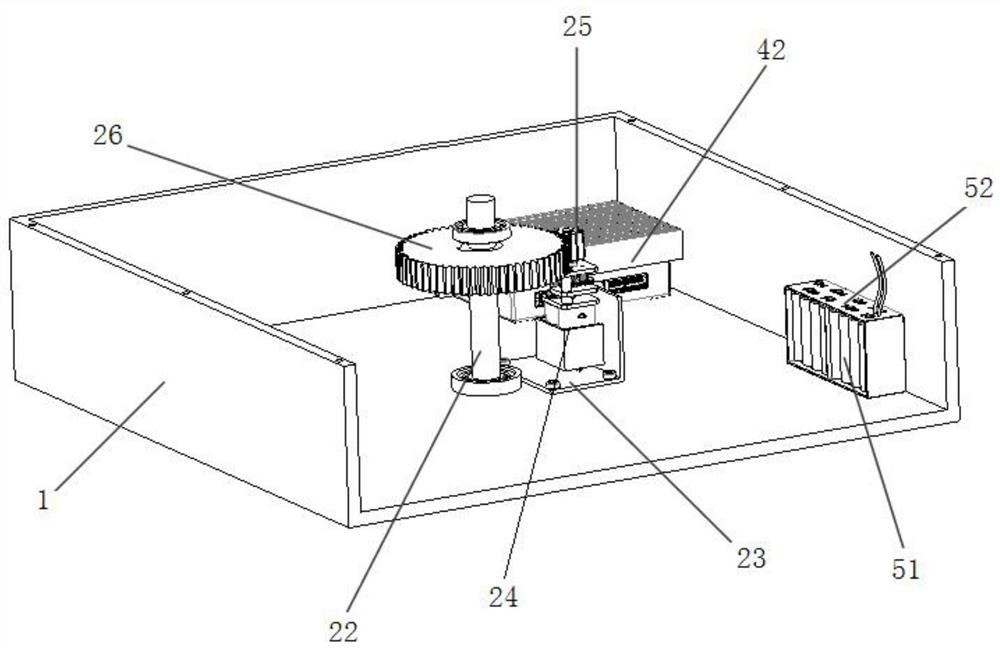

[0033] The rotatable storage mechanism 2 is used to carry the decommissioned parts to be photographed and carry the decommissioned parts to be photographed for rotation; specifically, as image 3 As shown, the base 1 has a cavity structure, and the rotatable storage mechanism 2 includes a storage platform 21 and a rotation drive assembly; the storage platform 21 is connected to the main shaft 22 of the rotation drive assembly and suspended on the base 1 above. The rotary drive assembly includes a reduction motor 24 connected to the motor seat 23 inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com