Two-stage sub-wavelength grating silicon-based light polarization beam splitting rotator based on asymmetric coupling

A sub-wavelength grating and asymmetric coupling technology, applied in light guides, optics, instruments, etc., can solve the problems of small device manufacturing tolerance, unfavorable on-chip system integration, large manufacturing tolerance, etc., to increase the overall error tolerance, Guaranteed extinction ratio performance, high polarization extinction ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation methods.

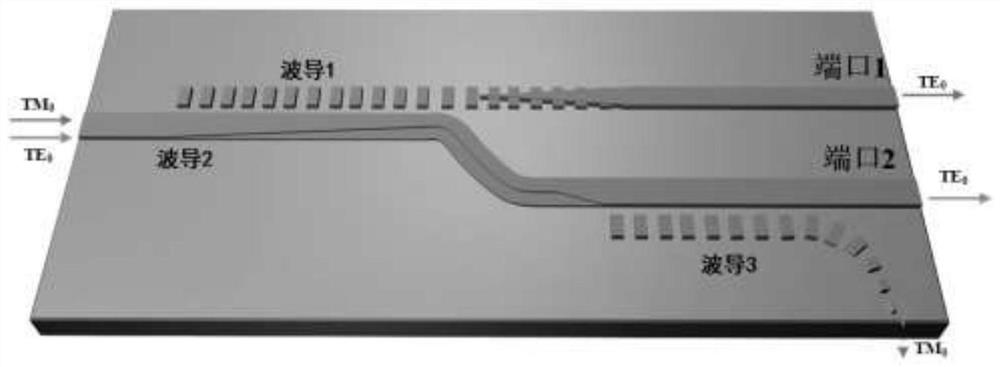

[0029] The two-stage sub-wavelength grating silicon-based light polarization beam splitting rotator based on asymmetric coupling of the present invention is as figure 1 As shown, silicon dioxide is used as the substrate, and air is used as the upper cladding to break the vertical symmetry; a silicon waveguide is used to form the main body of the polarization beam splitter rotator.

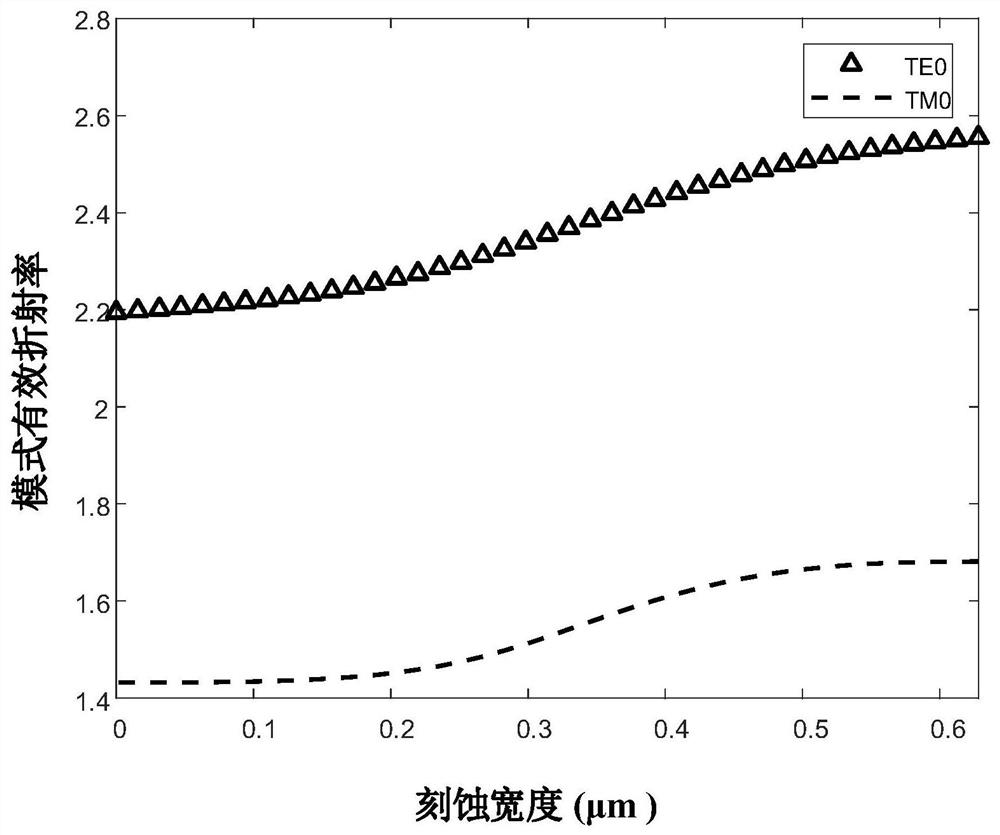

[0030] The silicon waveguide is divided into three parts: waveguide 1 is a one-stage coupling sub-wavelength grating waveguide, which equivalently widens the waveguide feature size, thereby increasing the manufacturing tolerance; waveguide 2 (or BUS waveguide) is a two-stage tapered etched waveguide, The first-stage tapered etching completes phase matching with waveguide 1 to achieve polarization rotation, and the second-stage etching restores t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com