A Stress-Strain Test-bed for Static Blade Adjustment Mechanism Considering the Effect of Temperature

An adjustment mechanism, stress-strain technology, applied in the direction of jet engine testing, mechanical component testing, gas turbine engine testing, etc., can solve the problems of unfavorable test and lack of test bench

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In conjunction with the accompanying drawings and the following embodiments, the present invention will be further described in detail. It will be appreciated that the specific embodiments described herein are intended to explain the present invention and is not intended to limit the invention.

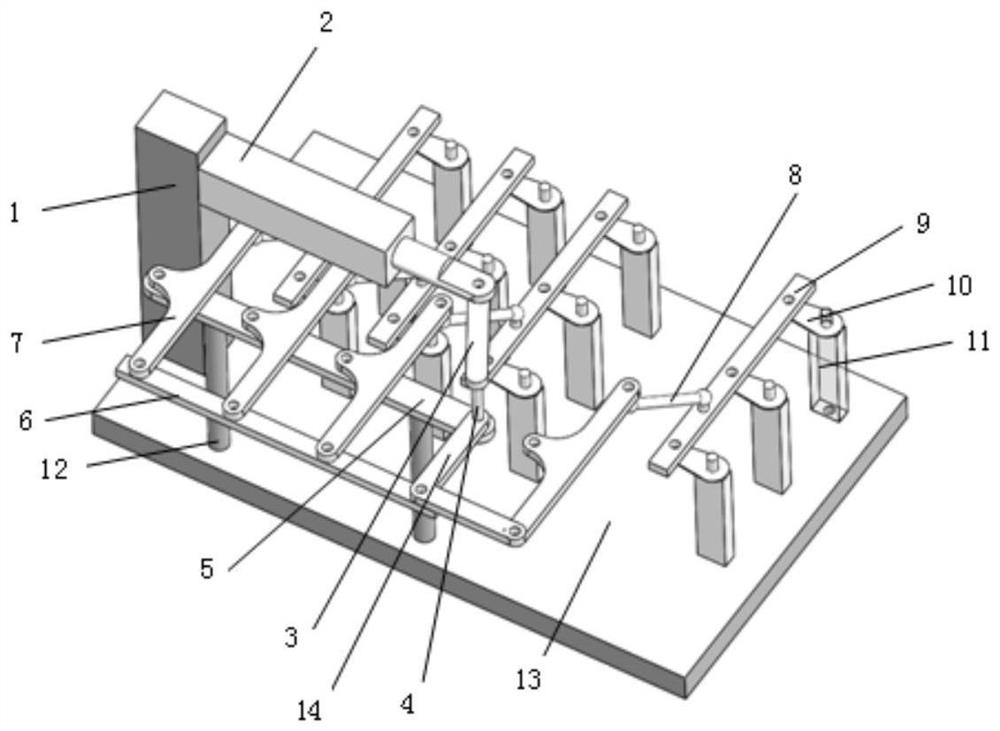

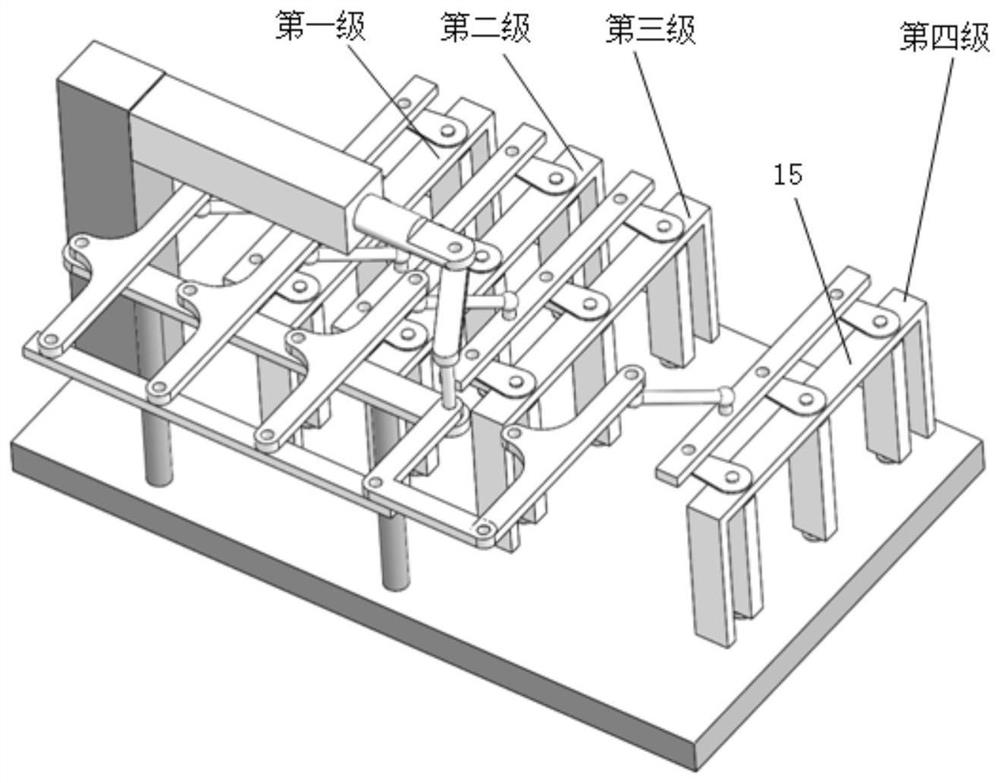

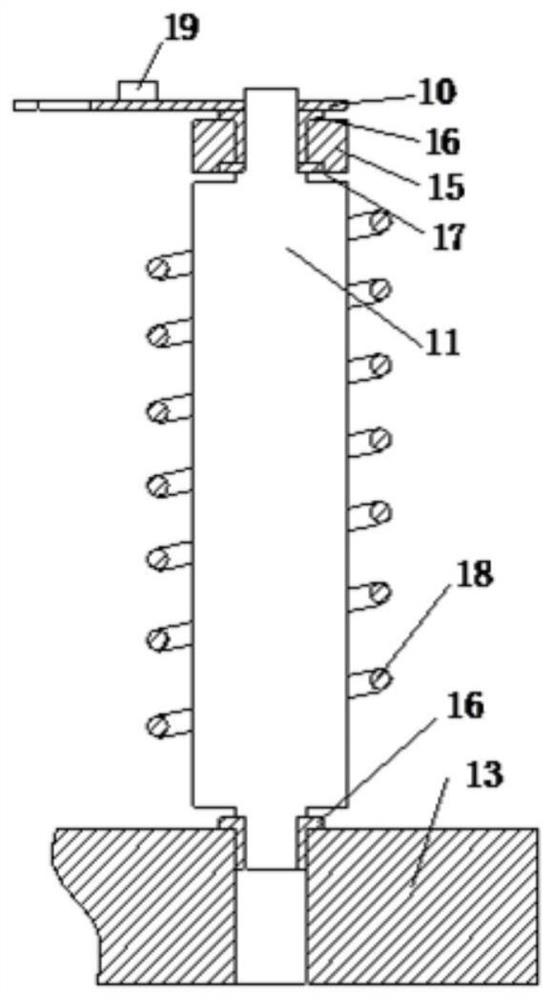

[0022] See Figure 1-3 The present invention provides a technical solution: considering the influence of temperature adjusting vanes stress strain test table means, comprising an inner casing 13, the top side of the casing 13 is provided with a linear motor mounting portion, and a linear motor mounting portion 1 is attached to the top side of the linear motor 2, the second end portion of the linear motor 3 is attached to the rocker, and the rocker shaft 3 is connected with the lock 4, the shaft 4 connected to the bottom plate 5 is fixed, and the rotary shaft 4 rotatably attached to the bottom of the fixing plate 5 shaft groove provided in the top, bottom locking shaft 4 is attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com