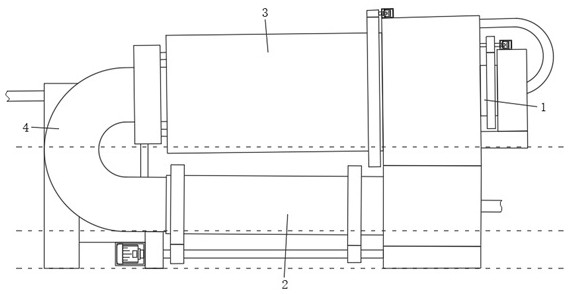

Automatic screening and balanced drying roller dryer

A drum dryer and automatic screening technology, applied in dryers, drying, non-progressive dryers, etc., can solve the problems of short drying temperature and drying time, incomplete drying of large particle materials, etc., to achieve same drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

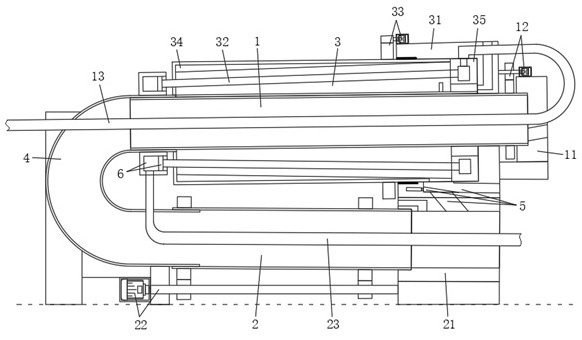

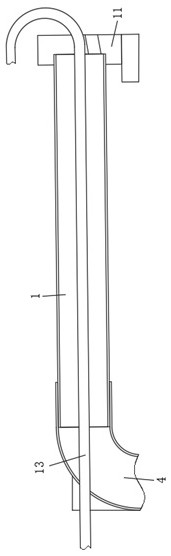

[0056] The second heat exchange tube 23 extends upwards and runs through one side of the elbow 4. One end of the third heat exchange tube 32 runs through the fine material drying cylinder 3, and the second heat exchange tube 23 and the third heat exchange tube 32 A rotating fit assembly 6 is connected between them; one end of the first heat exchange tube 13 extends into the third end cover 31, and the other end of the first heat exchange tube 13 runs through the elbow 4; the upper end of the fine material drying cylinder 3 An annular rotary cover 35 is welded, and the annular rotary cover 35 is limited to the inside of the third end cover 31, the other end of the third heat exchange tube 32 extends into the rotary cover 35, and passes through the rotary cover 35 and the first heat exchange tube 13 conduction; during drying, the drying air flow is introduced through the second heat exchange tube 23, enters the third heat exchange tube 32 through the rotating fitting assembly 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com