Environment-friendly garden waste drying treatment device

A garden waste and treatment device technology is applied in the field of environmentally friendly garden waste drying treatment devices, which can solve the problems of environmental pollution, waste of resources at the input end, and poor drying effect, and achieves good treatment effect, smooth feeding, Ease of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

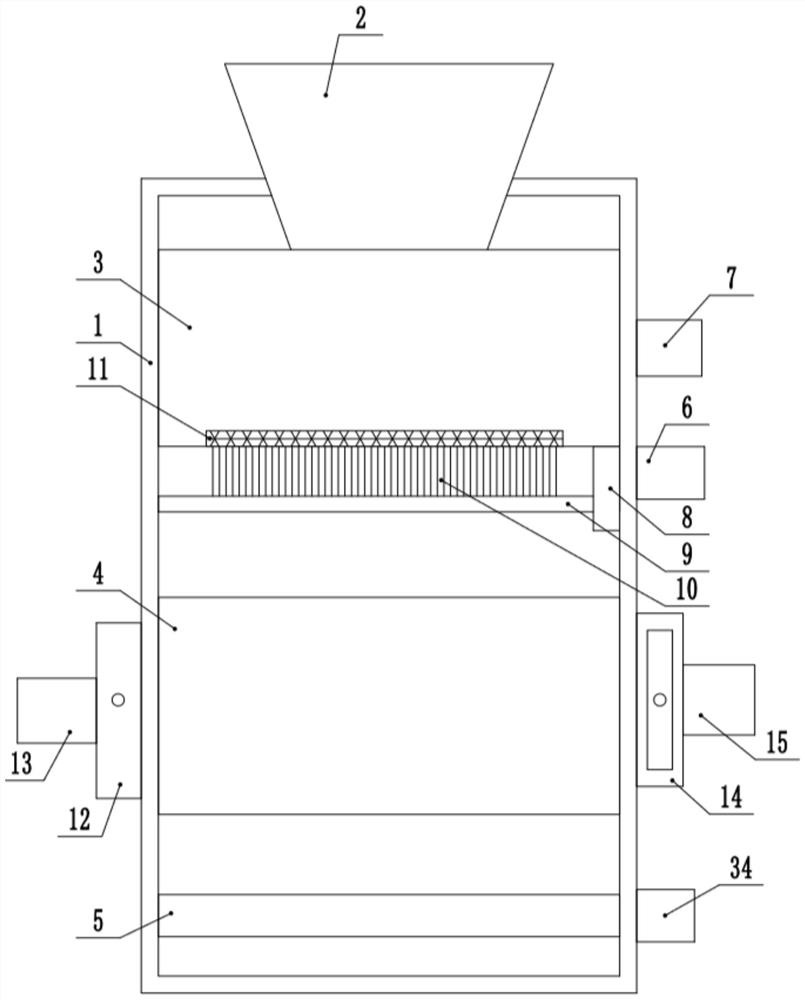

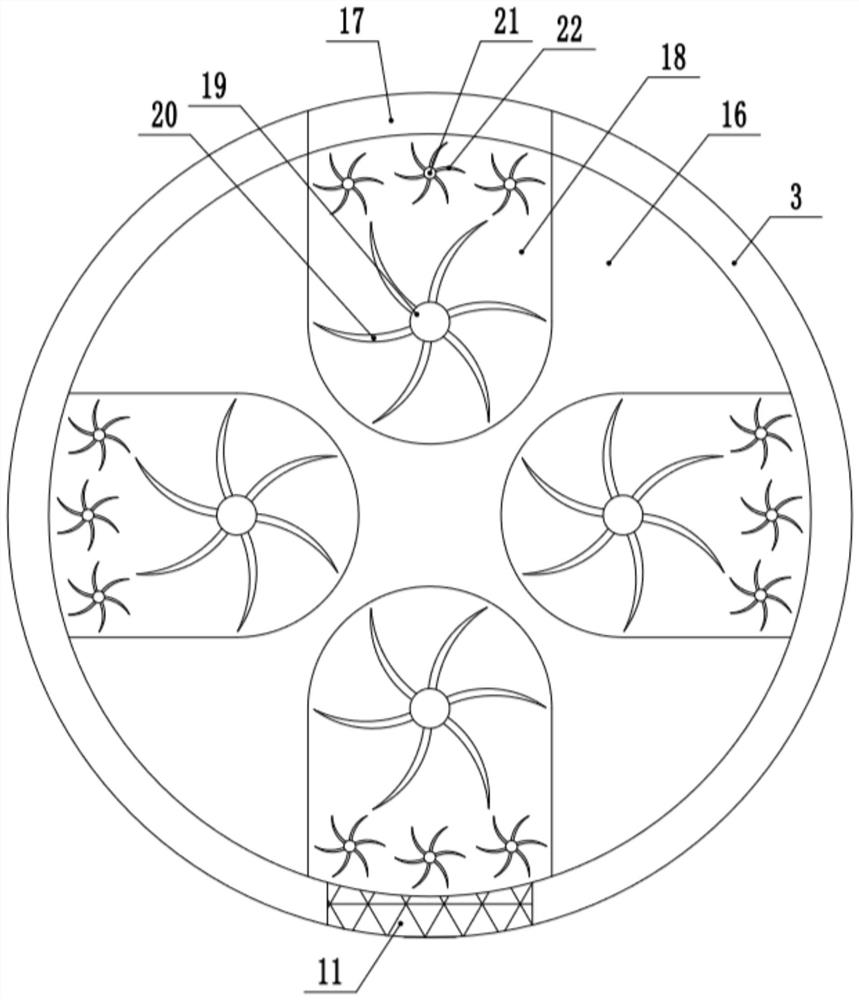

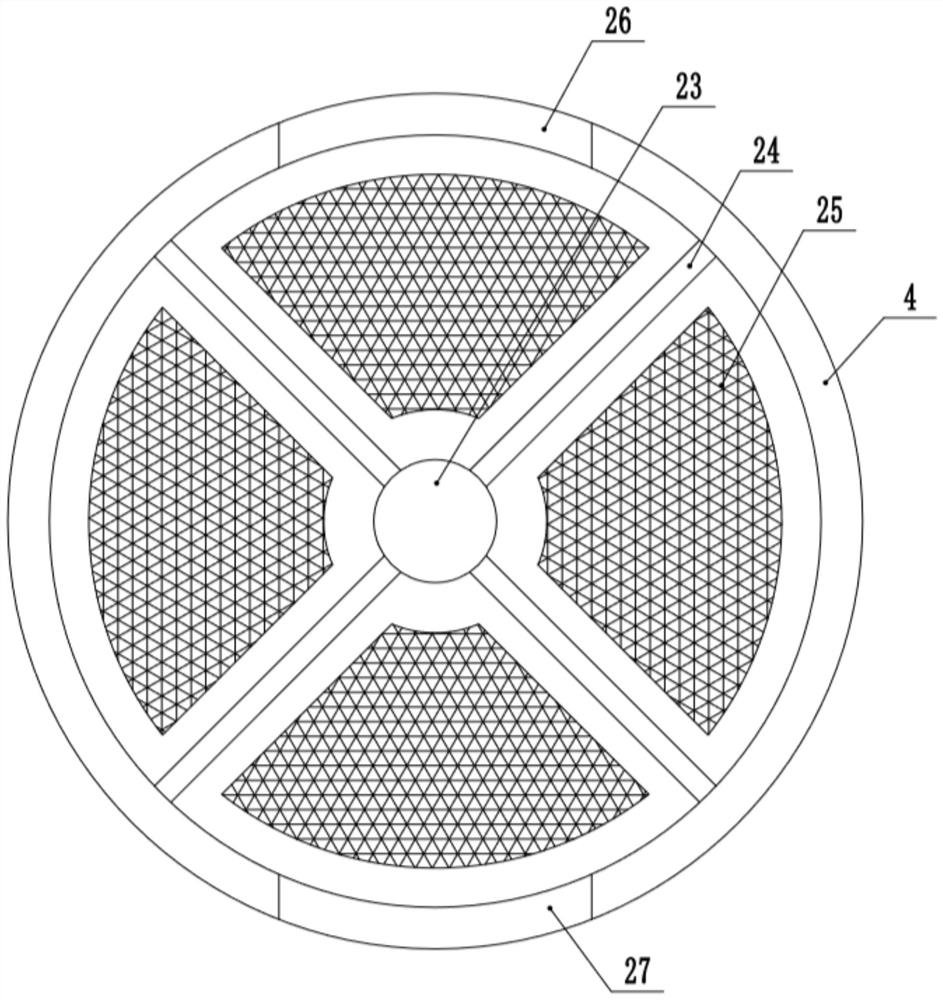

[0026] see Figure 1-5 , an environment-friendly garden waste drying treatment device, comprising a treatment box 1, the top of the treatment box 1 is fixedly connected to the feed hopper 2, the upper part of the treatment box 1 is fixedly connected to the pretreatment cylinder 3, and the top of the treatment box 1 is fixedly connected to the pretreatment cylinder 3. The lower part is fixedly connected to the drying cylinder 4. The pretreatment cylinder 3 is equipped with a partition crushing mechanism. The drying cylinder 4 is equipped with a drying mechanism. The bottom of the pretreatment cylinder 3 is equipped with a cleaning and anti-blocking mechanism. An air circulation conveying mechanism is provided, and a conveying mechanism is provided in the processing box 1 below the drying cylinder 4 .

[0027] Described subdivision pulverization mechanism comprises the rotating column 16 that is connected in the pretreatment cylinder 3 in rotation, and the outside of processing ...

Embodiment 2

[0035] see Figure 1-5 , the other content of this embodiment is the same as that of Embodiment 1, except that: the top and the bottom of the drying cylinder 4 are provided with a second feed port 26 and a second discharge port 27 respectively, and the second feed port A collection hopper 35 is fixedly connected to the feed opening 26 .

[0036] In the implementation process of the present invention, at first the garden waste is poured into the treatment box 1 from the feed hopper 2, and the waste enters the crushing groove 18 in the pretreatment cylinder 3, and is crushed by the main crushing blade 20 and the branch crushing blade 22. During the crushing process, the second drive motor 7 drives the rotating column 16 to rotate until the crushed waste falls from the filter screen 11, and falls into the drying cylinder 4 below after being cleaned by the dredging bristles, and is blown out by the blower. The wind dries the waste after being heated by the electric heating wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com