Boiler header connecting pipe with hot spinning hydraulic pressure end socket and machining method thereof

A boiler header and processing method technology, applied to boiler water pipes, steam boilers, steam boiler accessories, etc., can solve problems that affect production efficiency, cannot be reused, and the welding workload is large, so as to improve production efficiency and save manpower and material resources , Hot spinning forming simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

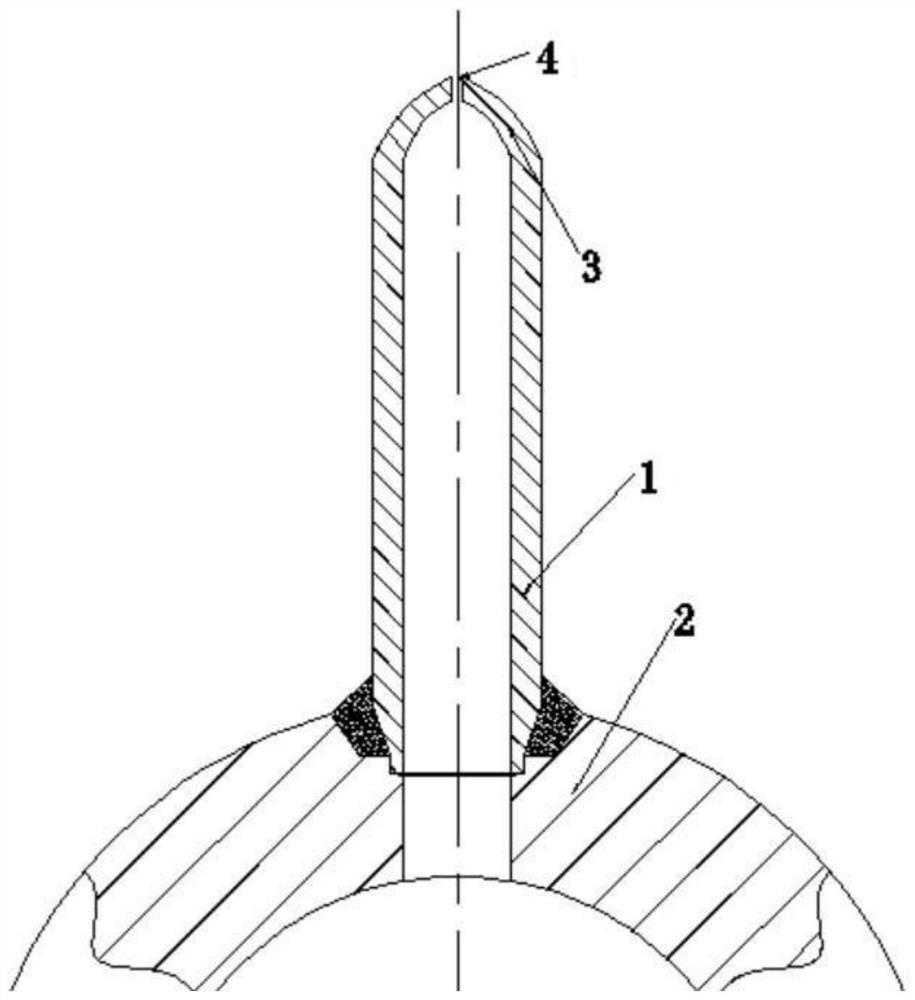

[0031] Such as figure 1 , the boiler header connecting pipe with hot spinning water pressure head of the present invention includes a connecting pipe body 1, and one end of the connecting pipe body 1 is formed by hot spinning to have a hydraulic pressure sealing head 3, the water pressure sealing head 3 is a hemisphere, and the hydraulic pressure The axial length of the sealing head 3 is 50% of the connection body 1 , and the thickness of the hydraulic sealing head 3 is greater than 90% of the wall thickness of the connection body 1 . The hot spinning hole 4 is left on the hydraulic head 3, the center of the hot spinning hole 4 is located on the axis of the connecting pipe body 1, and the diameter of the hot spinning hole 4 is 3-8mm. During the hydrostatic test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com