Light guide type lighting decoration device

A light guide and light guide channel technology, which is applied to lighting devices, fixed lighting devices, light guides of lighting devices, etc., can solve the problems of not effectively improving the brightness, waste of light at the opening, and uneven length direction, etc. Display effect, flexible shape design, less waste of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

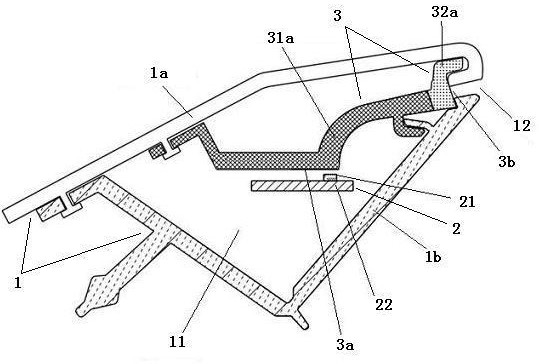

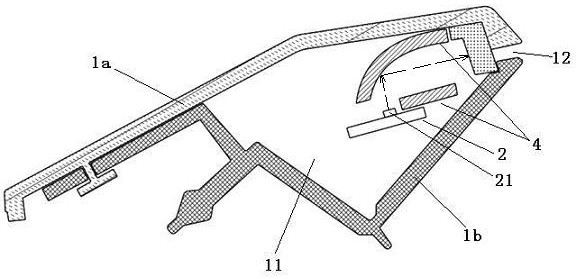

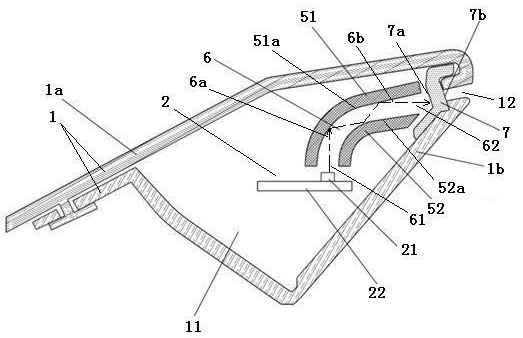

[0021] image 3 A schematic cross-sectional structure diagram of the light-guiding lighting decoration device according to the first embodiment of the present invention is shown. Figure 4 A schematic structural diagram of a light guide cover plate and a light guide bottom plate according to an embodiment of the present invention is shown. see image 3 and Figure 4 . The light guide lighting decoration device according to the first embodiment of the present invention includes a housing 1 , a light source 2 , a non-transparent light guide cover plate 51 and a non-transparent light guide bottom plate 52 .

[0022] The housing 1 has an inner cavity 11 and a light outlet 12 . In this embodiment, the housing 1 is composed of a first housing part 1 a and a second housing part 1 b, and the first housing part 1 a and the second housing part 1 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com