Double-step type pressurizing oil cylinder

A pressurized oil cylinder and oil pressure chamber technology, applied in the field of hydraulic cylinders, can solve problems such as excessively large cylinder plug volume design, poor cylinder pressure, and large oil consumption of the oil cylinder, and achieve overall energy saving, stability improvement, and reduction The effect of small energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

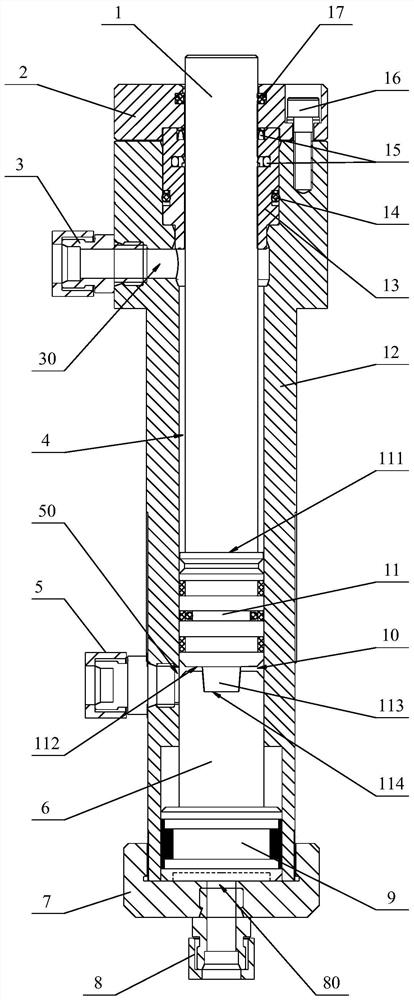

[0030] refer to figure 1 , a two-step booster cylinder provided in this embodiment includes a cylinder 12, a front cylinder head 2 arranged at one end of the cylinder 12, and a front cylinder head 2 arranged at the end of the cylinder 12 away from the front cylinder head 2 A rear cylinder head 7, and a first piston rod assembly and a second piston rod assembly arranged in the cylinder barrel 12.

[0031] Combine the following figure 2 , the cylinder 12 includes an outer wall and an opposite inner wall, the front cylinder cover 2 and the rear cylinder cover 7 are installed on both ends of the cylinder tube 12 by a predetermined number of screws 16, the front cylinder cover 2 and the rear cylinder cover 7 A guide sleeve 13 is embedded between the cylinders 12 , the outer wall of the guide sleeve 13 fits with the inner wall of the cylinder 12 , and a first seal 14 is provided.

[0032] The first piston rod assembly includes a first piston 11 and a first piston rod 1 connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com