Reinforced negative pressure barrel-single pile combined type maritime work foundation structure

A basic structure, negative pressure bucket technology, applied in basic structure engineering, construction and other directions, can solve the problems of poor foundation bearing capacity, construction difficulty and increased cost, and achieves improved anti-tilt bearing capacity, reduced material cost, and good anti-tilt resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments will specifically illustrate the reinforced negative pressure barrel-single pile composite marine foundation structure of the present invention in conjunction with the accompanying drawings.

[0023]

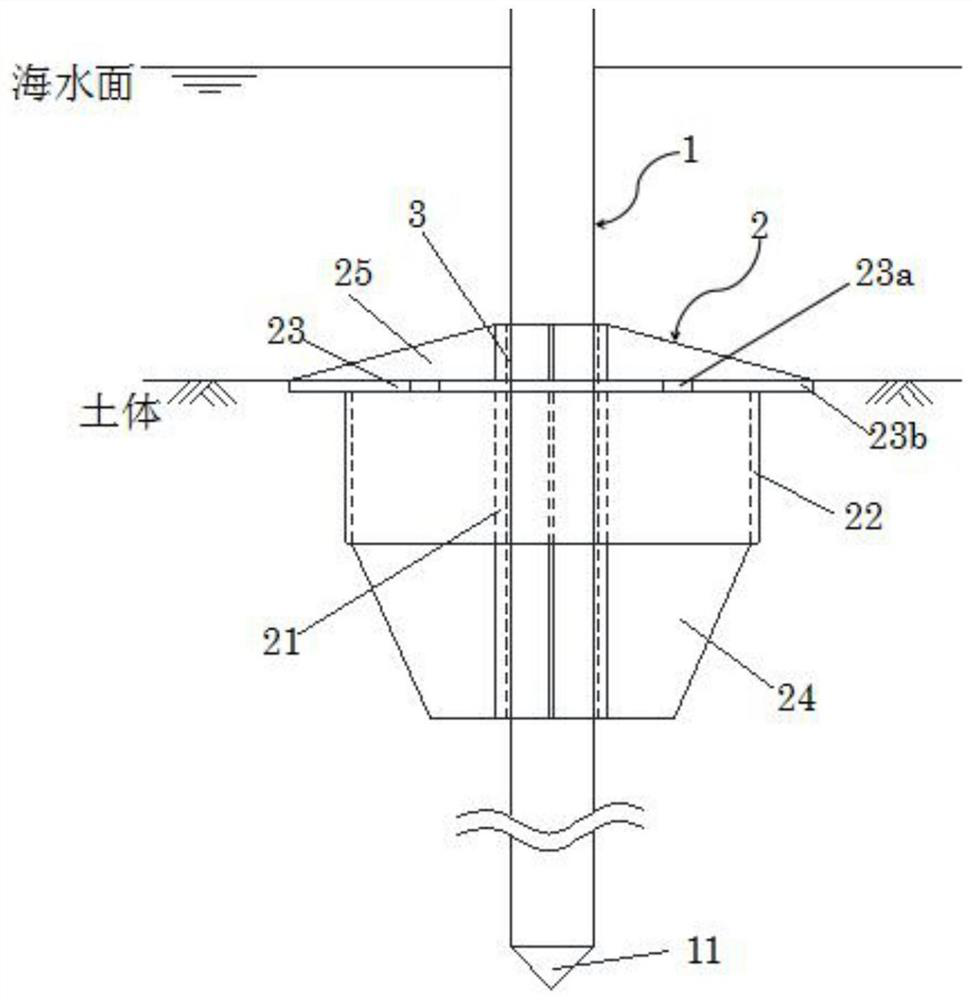

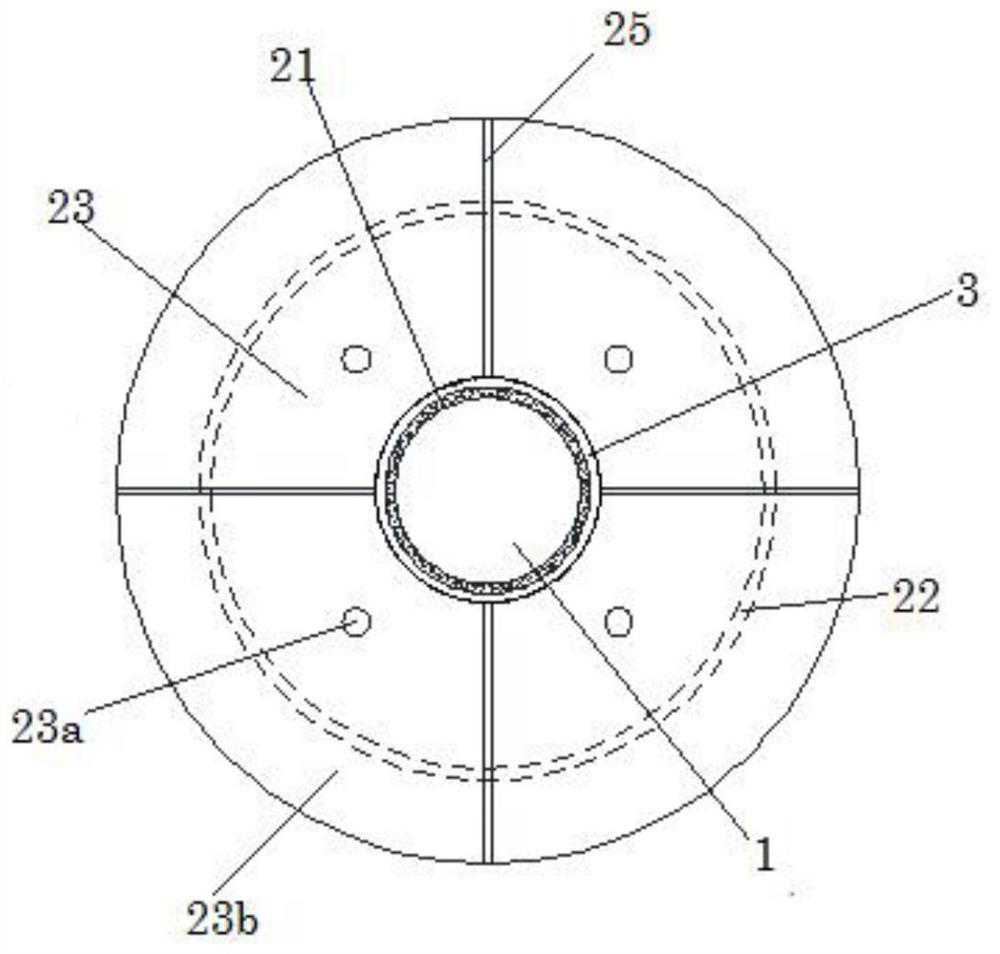

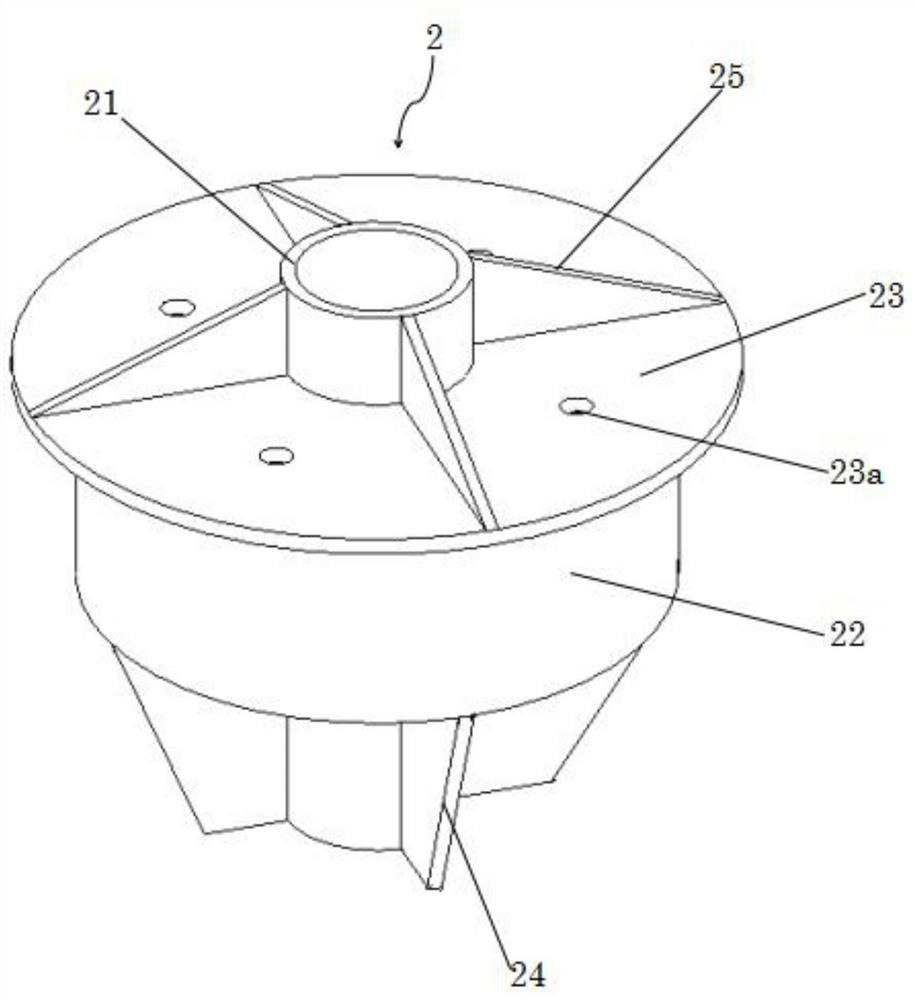

[0024] Such as figure 1 As shown, the reinforced negative pressure barrel-single pile composite offshore foundation structure of this embodiment includes a single pile 1 and a negative pressure barrel 2 .

[0025] Such as Figure 1 to Figure 3 As shown, the negative pressure barrel 2 includes an inner barrel wall 21 , an outer barrel wall 22 , an annular top plate 23 , a partition plate 24 and a support plate 25 . The negative pressure barrel 2 is an integrated structure formed by welding high-strength steel plates, or an integrated structure made of high-strength reinforced concrete.

[0026] The inner barrel wall 21 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com