Highway pavement subbase construction method

A construction method and sub-base technology, applied in the field of building construction, can solve the problems of use in areas with low traffic volume, poor test indicators such as liquid-plastic limit, high construction cost, etc., and achieve the improvement of measured deflection value, low cost, The effect of improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A construction method for a highway pavement subbase, comprising:

[0034] In step S1, before the subbase layer is spread, the lower bearing layer below it is sprinkled with water and cleaned, and the lower bearing layer is checked and accepted according to the specifications and design requirements;

[0035] Step S2: stake out before measurement: restore the center line before flattening, set measuring points at different intervals for straight sections and curves, and multiply the design thickness by the loose paving coefficient as the flattened thickness;

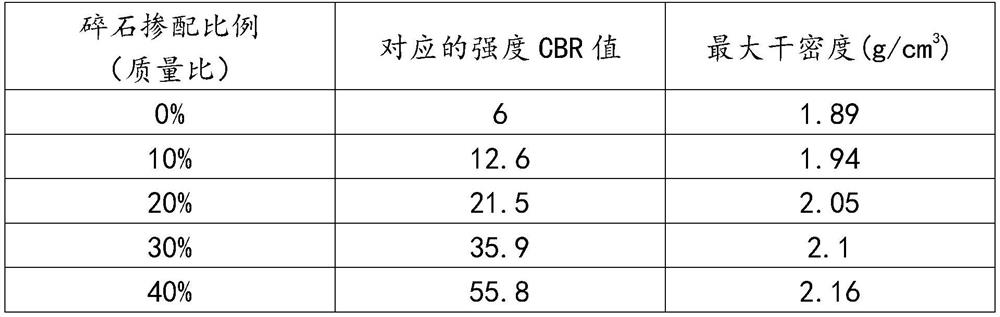

[0036] Step S3 adopts the mass ratio, mixing 70% gravel soil with 30% crushed stone mixture for on-site mixing construction, including:

[0037] In step S31, according to the calculated gravel soil, stake out bamboo piles on the slope according to the designed spacing, evenly stack the gravel soil on the roadbed, and use a grader to initially level the shape;

[0038] Step S32 calculates the amount of crushed sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com