Electrophoretic coating device with colors convenient to change

An electrophoretic coating and color technology, applied in electrolytic coatings, electrophoretic plating, coatings, etc., can solve problems such as high use limitations, high energy consumption, equipment instability, etc., to improve work efficiency and improve practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

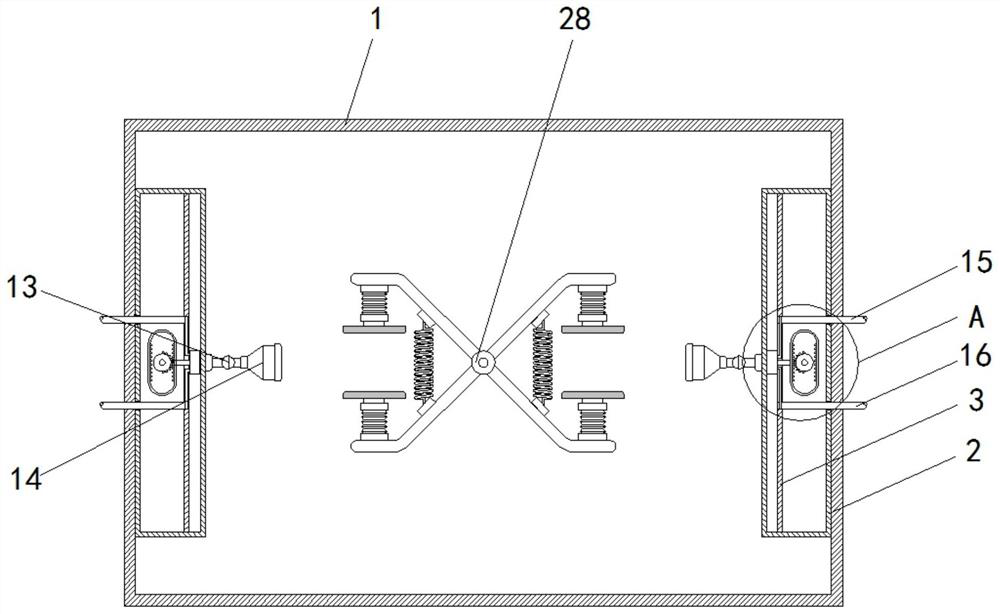

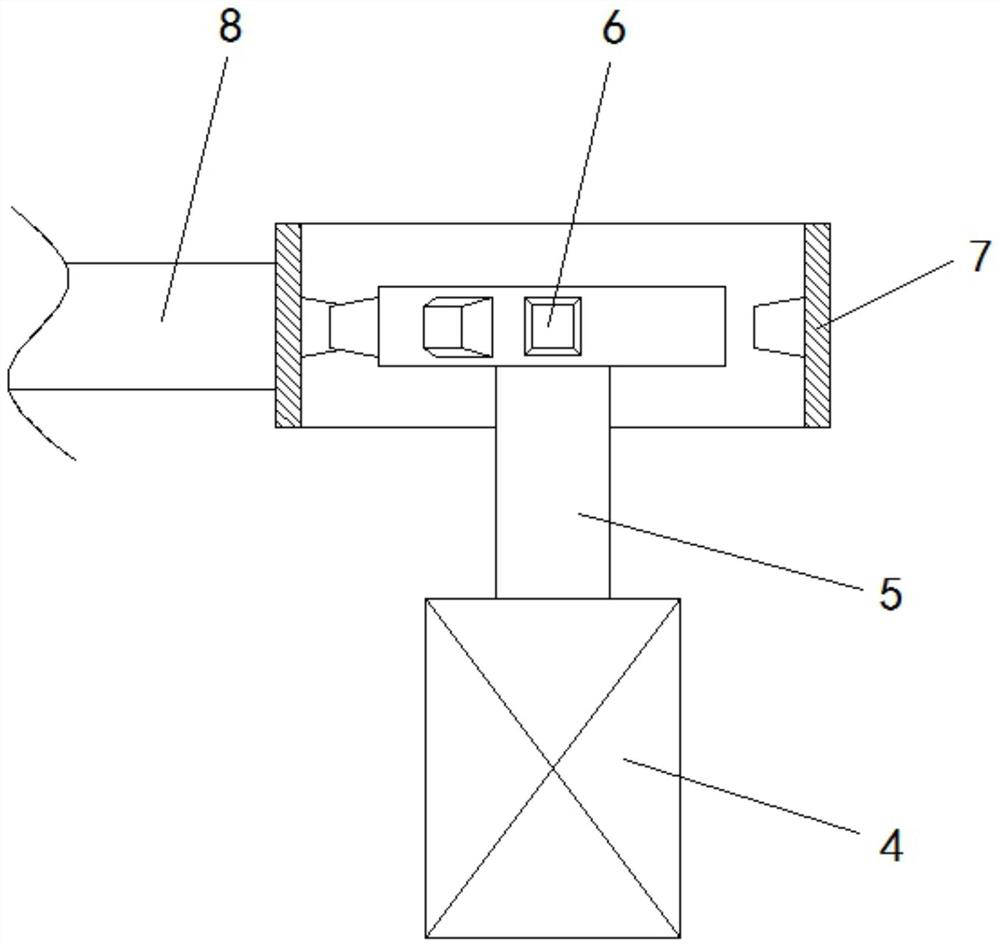

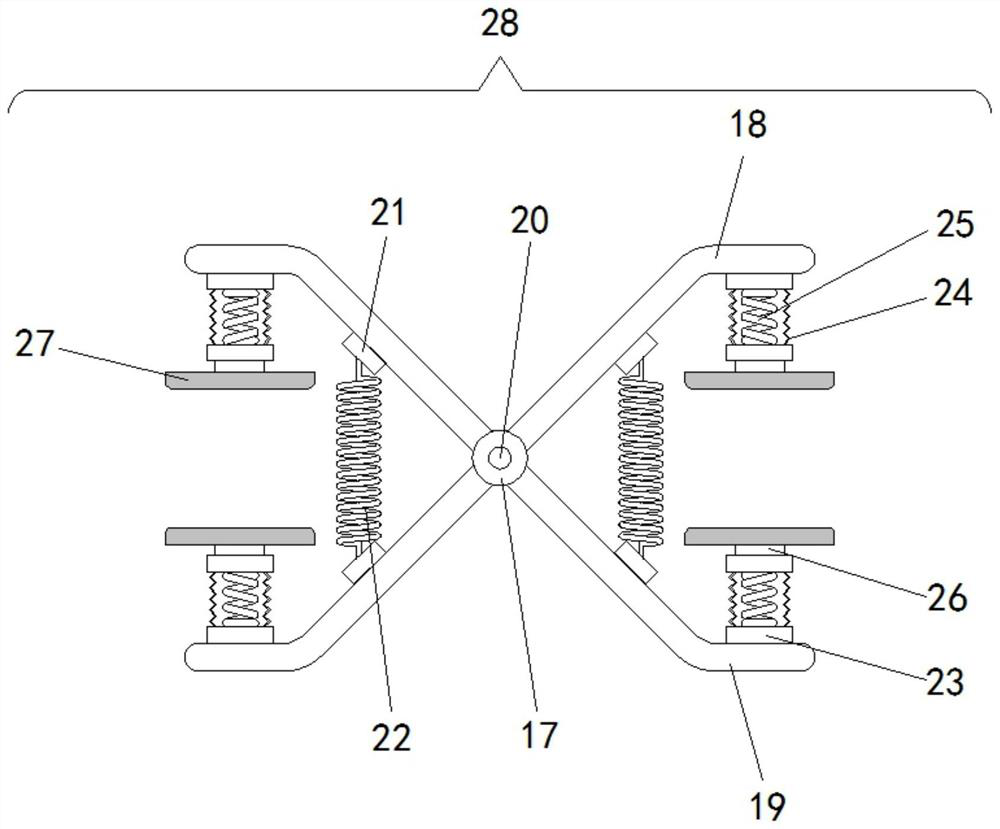

[0026] as attached figure 1 To attach Figure 4 Shown:

[0027] The present invention provides an electrophoretic coating device for easy color replacement, which includes a main body 1, a casing 2 is arranged inside the main body 1, a fixed baffle 3 and a driving mechanism 4 are arranged inside the casing 2, and the front side of the driving mechanism 4 A rotating shaft 5 is installed in a movable manner, and the front side of the rotating shaft 5 is fixedly equipped with a driving gear 6, and the driving gear 6 is connected with a movable block 7 through meshing, and a connecting rod 8 is fixedly installed on the left side of the movable block 7, and the left end of the connecting rod 8 is fixed. The slider 9 is installed, the left side of the housing 2 is provided with an electrophoretic nozzle 14, and the left side of the housing 2 is provided with a mounting part 12, and the electrophoretic nozzle 14 is stably installed through the mounting part 12, so that the electroph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com