Electrophoretic coating method

An electrophoretic coating and electrophoresis technology, which is applied in electrophoretic plating, electrolytic coatings, chemical instruments and methods, etc., can solve problems such as affecting the efficiency and effect of electrophoretic coating on workpieces, increasing the rejection rate of electrophoretic coating on workpieces, and ineffective effects. , to achieve the effect of improving market competitiveness, safe and convenient use, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

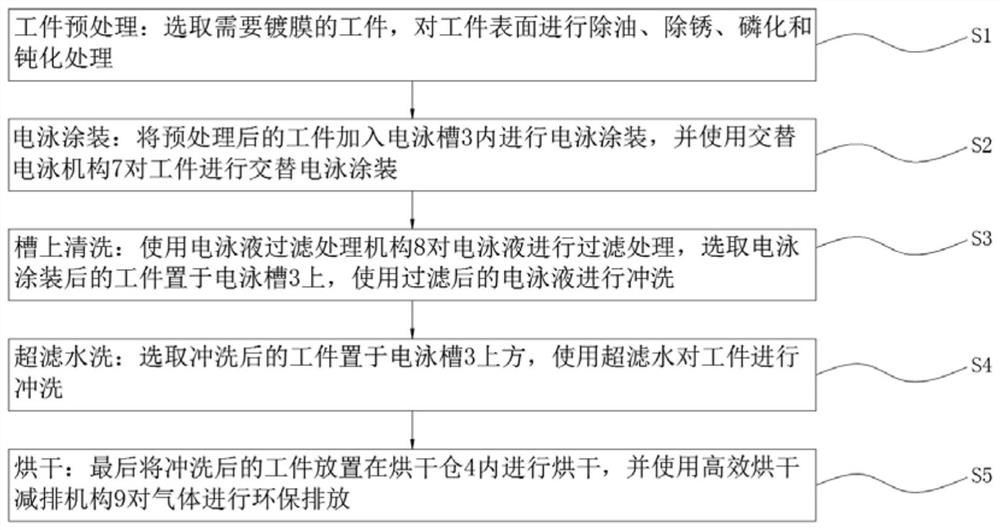

[0044] Example: such as figure 1 As shown, the present invention provides technical scheme, a kind of electrophoretic coating coating method, comprises the steps:

[0045] S1. Workpiece pretreatment: select the workpiece that needs to be coated, and perform degreasing, rust removal, phosphating and passivation treatment on the surface of the workpiece;

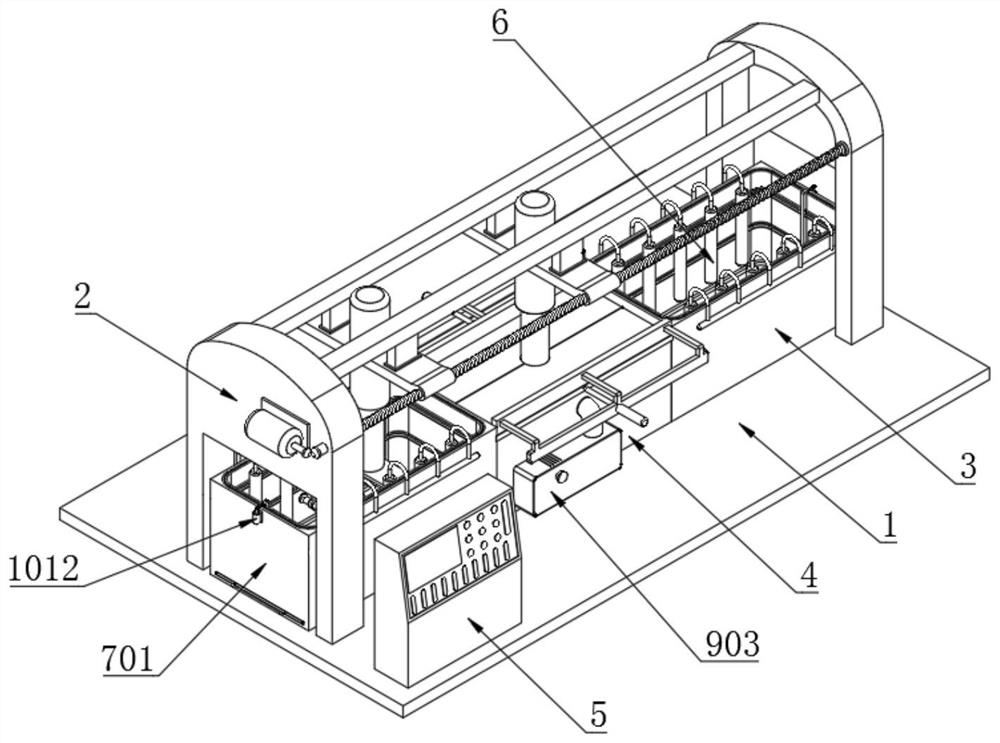

[0046] S2. Electrophoretic coating: add the pretreated workpiece into the electrophoretic tank 3 for electrophoretic coating, and use the alternating electrophoretic mechanism 7 to perform alternate electrophoretic coating on the workpiece;

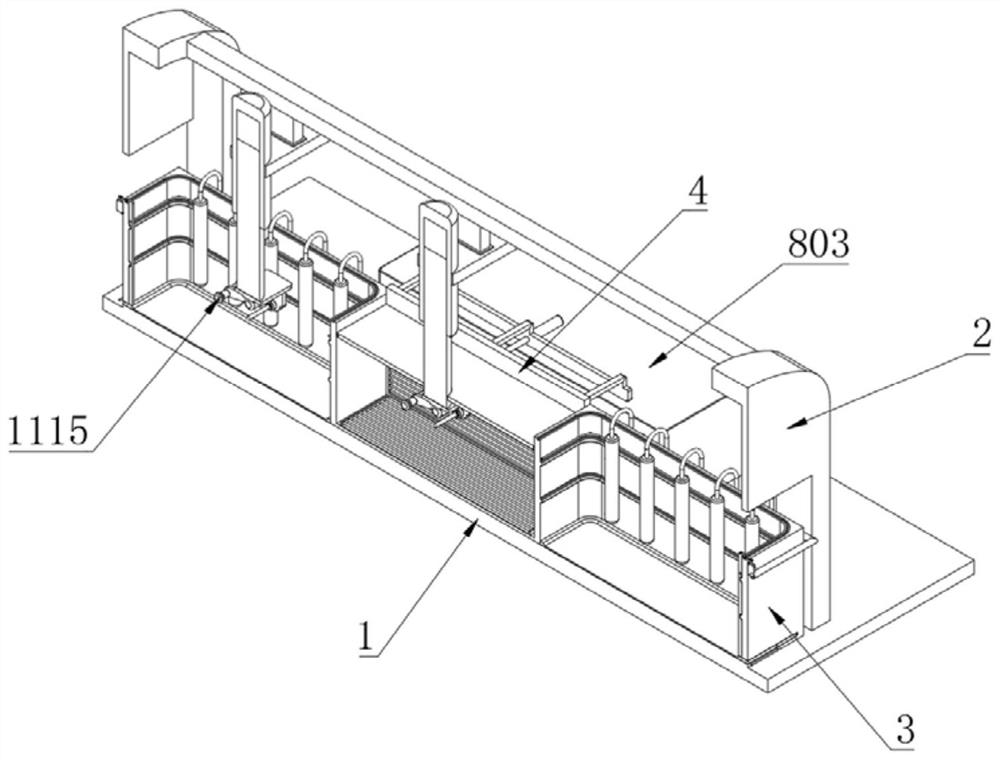

[0047] S3. Cleaning on the tank: use the electrophoretic fluid filtering mechanism 8 to filter the electrophoretic fluid, select the workpiece after electrophoretic coating and place it on the electrophoretic tank 3, and use the filtered electrophoretic fluid to rinse;

[0048] S4. Washing with ultrafiltration water: select the washed workpiece and place it above the electrophoresis tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com