Oil, gas, water and sand four-phase separation integrated device

A phase separation and three-phase separator technology, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems affecting the separation effect of equipment, long installation and commissioning period, and large floor space, so as to improve equipment reuse. Utilization, compact structure, space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

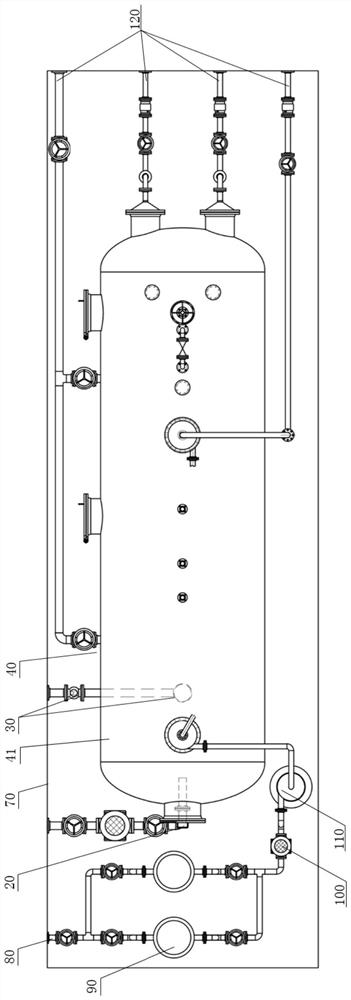

[0068] see figure 1 , an integrated device for four-phase separation of oil, gas, water and sand, comprising: a skid seat 70, a crude oil inlet pipe 80, a first sand removal filter 90, a liquid inlet pump 100, a sand removal cyclone 110, a flushing Sand assembly 20 , sand discharge box 30 , three-phase separator 40 and discharge pipe assembly 120 . The crude oil inlet pipe 80 is fixed on the skid seat 70 , and the crude oil inlet pipe 80 is connected to one end of the first desanding filter 90 . The first sand removal filter 90 is fixed on the skid 70 , and the other end of the first sand removal filter 90 is connected to the liquid inlet of the liquid inlet pump 100 . The liquid inlet pump 100 is fixed on the skid base 70 , and the liquid outlet of the liquid inlet pump 100 is connected with the desanding cyclone 110 . The sand removal cyclone 110 is fixed on the skid seat 70 , and the sand removal cyclone 110 is connected to the liquid inlet on the top of the tank body 41 ...

Embodiment 2

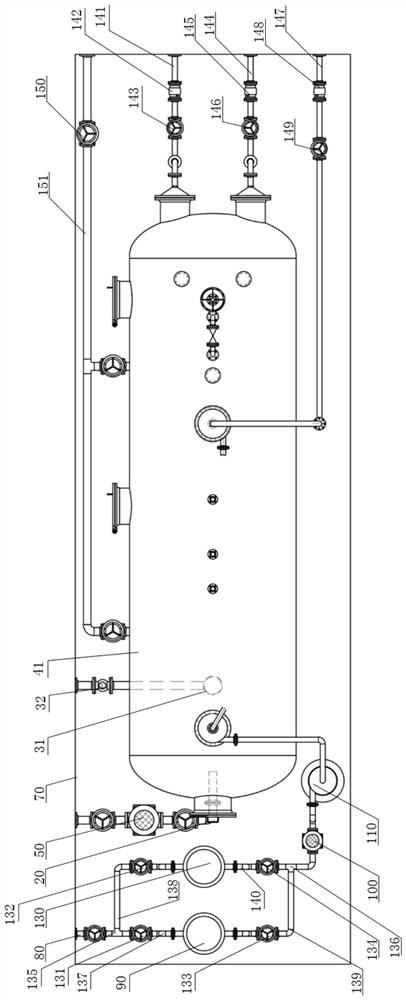

[0074] Such as figure 2 As shown, this embodiment further defines an integrated device for four-phase separation of oil, gas, water and sand on the basis of the first embodiment, and further includes: a second sand removal filter 130 . The second sand removal filter 130 is fixed on the skid seat 70, one end of the second sand removal filter 130 is connected with the crude oil inlet pipe 80, and the other end of the second sand removal filter 130 is connected with the liquid inlet of the liquid inlet pump 100. port connection. In this embodiment, the first sand removal filter 90 and the second sand removal filter 130 can work alternately, and when one of the sand removal filters is shut down for cleaning, the other sand removal filter can work normally, ensuring continuous operation of the system.

[0075] Further, as figure 2 As shown, a four-phase separation integrated device for oil, gas, water and sand also includes a first valve 131, a second valve 132, a third valve ...

Embodiment 3

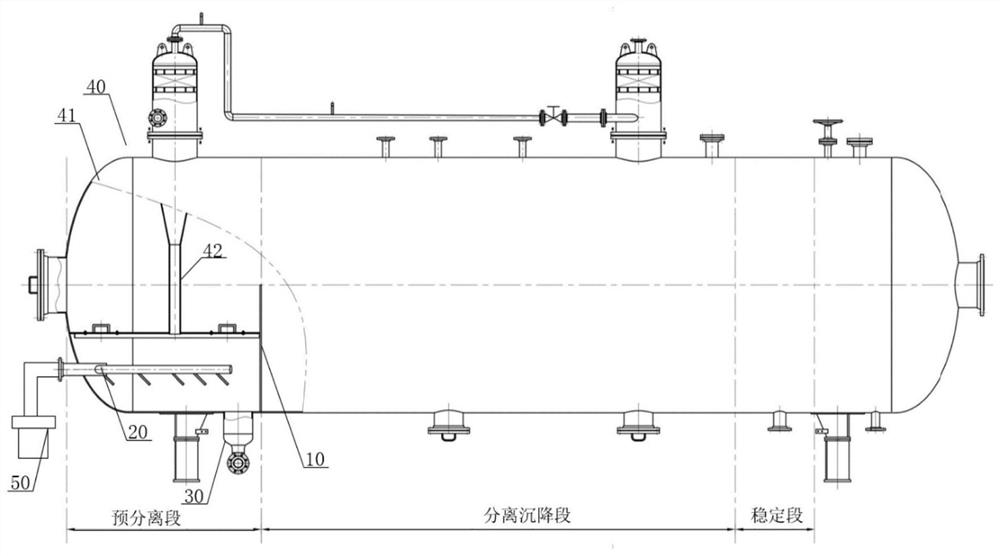

[0086] Such as image 3 As shown, this embodiment further defines an integrated device for four-phase separation of oil, gas, water and sand on the basis of the first and second embodiments, and further includes: a sand limiting plate 10 . In this embodiment, the tank body 41 of the horizontal three-phase separator 40 can be sequentially divided into three sections for three-phase separation treatment of crude oil, namely a pre-separation section, a separation and settlement section, and a stabilization section. The sand limiting plate 10 is fixed at the end of the pre-separation section in the tank body 41 of the three-phase separator 40, the two ends of the sand limiting plate 10 are fixedly connected with the inner wall of the tank body 41, and the bottom end of the sand limiting plate 10 is connected to the tank body. The bottom of 41 is fixedly connected, and there is a certain distance between the top of sand limiting plate 10 and the top of tank body 41 . The sand limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com