Alkene co-cracking catalyst and alkene mixed catalytic cracking method

A catalyst and co-cracking technology, used in catalytic cracking, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of catalyst loss, high coking amount, low total conversion rate and low propylene selectivity yield, etc., and achieve low wear and coking. Low volume, the effect of increasing the overall conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) Preparation of ZSM-5

[0060] First, tetraethyl orthosilicate, sodium aluminate, tetrapropylammonium hydroxide, ammonia and water are mixed according to 100SiO 2 :1Al 2 o 3 :20TPABr:120NH 3 ·H 2 O:2000H 2 The molar ratio of O was mixed, then crystallized at 80°C for 12h, and then crystallized at 180°C for 48h to obtain ZSM-5 with a grain size of 500-3000nm and a silicon-aluminum molar ratio of 100, then washed and pumped Filter and dry at 120°C for 12 hours, and then calcined at 600°C for 10 hours to obtain molecular sieve raw material ZSM-5.

[0061] (2) Alkali treatment of catalyst carrier

[0062] The above-mentioned molecular sieve raw material ZSM-5 was mixed with 0.4mol / L NaOH solution according to the mass ratio of 1:6, then exchanged at 90°C for 2h, then washed to neutrality, then dried at 120°C for 12h, Calcined at 540°C for 2h.

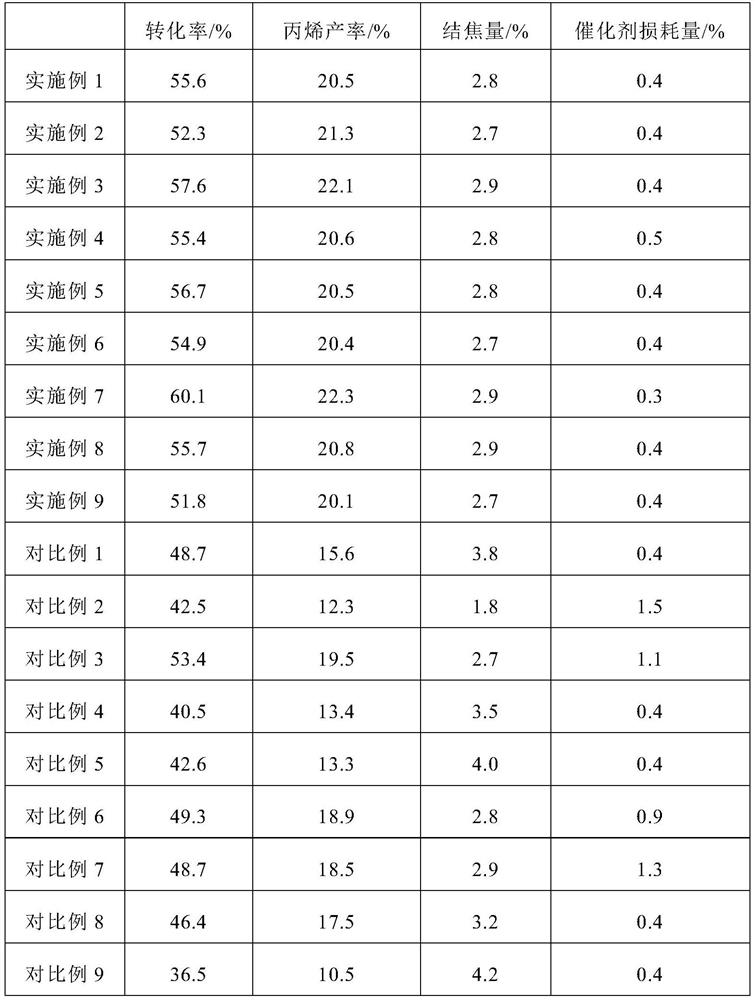

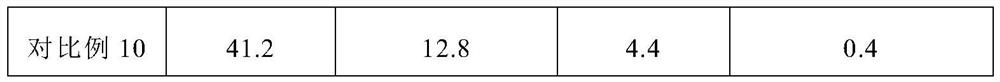

[0063] Mix ZSM-5 molecular sieves with 1mol / L ammonium nitrate solution at a mass ratio of 1:10, then perform ammonium e...

Embodiment 2

[0079] The catalyst was prepared according to the same process as in Example 1, except that the supported non-metallic elements were different.

[0080] Non-metal element impregnation modification steps are:

[0081] (3) boric acid and (NH 4 ) 2 SO 4 The solution is mixed to form an impregnating solution, and the mass ratio of the impregnating solution to HZSM-5 is 0.5:1, and B and S are impregnated on HZSM-5, so that the loading of B is 0.5wt%, and the loading of S is 0.8wt %. Then it was aged at room temperature for 6 hours, dried at 120° C. for 12 hours, and calcined at 540° C. for 4 hours.

[0082] All the other operations are the same as in Example 1.

[0083] The catalytic effect evaluation experiment of the catalyst is the same as in Example 1, and the results are shown in Table 2.

Embodiment 3

[0085] The catalyst was prepared according to the same process as in Example 1, except that the supported metal elements were different, and the conditions for impregnating and modifying the metal elements were different.

[0086] The specific operation of impregnating and modifying HZSM-5 with metal elements is as follows:

[0087] (5.1) Mo impregnation on hydrothermally treated HZSM-5

[0088] First, ammonium molybdate was dissolved in dilute ammonia solution with pH = 8.5, heated to 90°C to dissolve, and then Mo was impregnated on the hydrothermally aged HZSM-5 at a mass ratio of 0.4:1 at room temperature to obtain The loading amount of Mo is 0.2wt%, and then it is aged at room temperature for 6h, dried at 120°C for 12h, and calcined at 540°C for 4h.

[0089] (5.2) Impregnation of Mn, Ca and La on HZSM-5 loaded with Nb

[0090] MnCl 2 , CaCl 2 and La(NO 3 ) 3 After mixing the citric acid solution and HZSM-5 according to the mass ratio of 0.3:1, impregnating Mn, Ca and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com