Method for preparing farnesene by using biodiesel by-product

A biodiesel and farnesene technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of unfavorable sustainable large-scale production and high price, and achieve sustainable large-scale production , low price, and the effect of improving secretion and synthesis ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

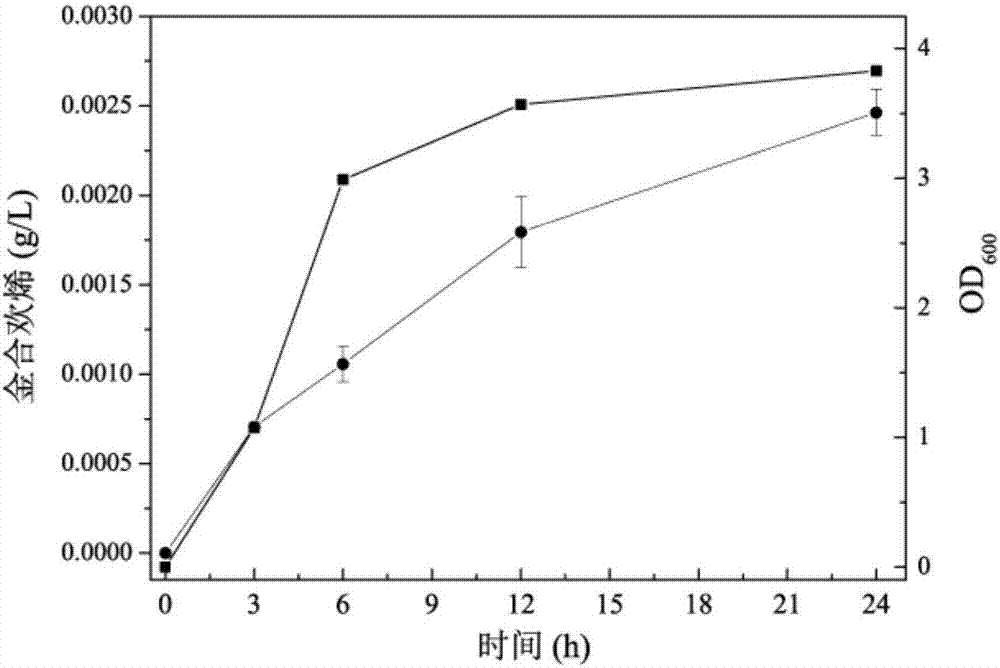

Embodiment 1

[0046] Biodiesel by-product purification

[0047] The initial biodiesel by-product was centrifuged at 3000rpm for 5min to remove insoluble substances; part of the methanol was removed through distillation (the temperature was controlled at about 65°C), and 5% phosphoric acid was added for neutralization, and the purified glycerin was obtained by centrifugation, and the glycerin concentration was 33.4% (w / w), for the preparation of farnesene.

[0048] Construction of recombinant host cell F1

[0049] According to the primers in Table 1, using Escherichia coli and Saccharomyces cerevisiae as templates, the corresponding DNA sequences of all enzymes in the MVA pathway (except farnesene synthase) were obtained by PCR amplification. The cDNA sequence of farnesene synthase is selected from the cDNA sequence of artemisinin, and the gene DNA sequence is obtained by gene synthesis. According to the DNA sequence obtained above, the pEASY-UniSeamless Cloning and Assembly Ki technology...

Embodiment 2

[0056] Biodiesel by-product purification

[0057] The initial biodiesel by-product was centrifuged at 15,000rpm for 60min to remove insoluble substances; part of the methanol was removed through distillation (the temperature was controlled at about 65°C), and 60% phosphoric acid was added for neutralization, and the purified glycerin was obtained by centrifugation, and the glycerol concentration was 65.7% (w / w), for the preparation of farnesene.

[0058] Construction of recombinant host cell F2

[0059] According to the primers in Table 2, using Escherichia coli DNA as a template, the corresponding DNA sequences of all enzymes in the MVA pathway (except farnesene synthase) were obtained by PCR amplification. The cDNA sequence of farnesene synthase is selected from the cDNA sequence of artemisinin, and the gene DNA sequence is obtained by gene synthesis. According to the DNA sequence obtained above, the pEASY-Uni Seamless Cloning and Assembly Ki technology was used to constr...

Embodiment 3

[0066] Biodiesel by-product purification

[0067] The initial biodiesel by-product was centrifuged at 7000rpm for 20min to remove insoluble substances; part of the methanol was removed through distillation (the temperature was controlled at about 65°C), and 40% phosphoric acid was added for neutralization, and the purified glycerin was obtained by centrifugation, and the glycerol concentration was 63.8% (w / w), for the preparation of farnesene.

[0068] Construction of recombinant host cell F3

[0069] According to the primers in Table 1, using Escherichia coli and Enterococcus faecalis group DNA as templates, the corresponding DNA sequences of all enzymes in the MVA pathway (except farnesene synthase) were obtained by PCR amplification. The cDNA sequence of farnesene synthase is selected from the cDNA sequence of artemisinin, and the gene DNA sequence is obtained by gene synthesis. According to the DNA sequence obtained above, the pEASY-UniSeamless Cloning and Assembly Ki t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com