VCSEL chip gold film etching solution and etching method thereof

An etching solution and chip technology, applied in chemical instruments and methods, surface etching compositions, electrical components, etc., can solve problems such as large roughness and irregular morphology of electroplated gold layer, and achieve improved affinity and high etching. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with accompanying drawing:

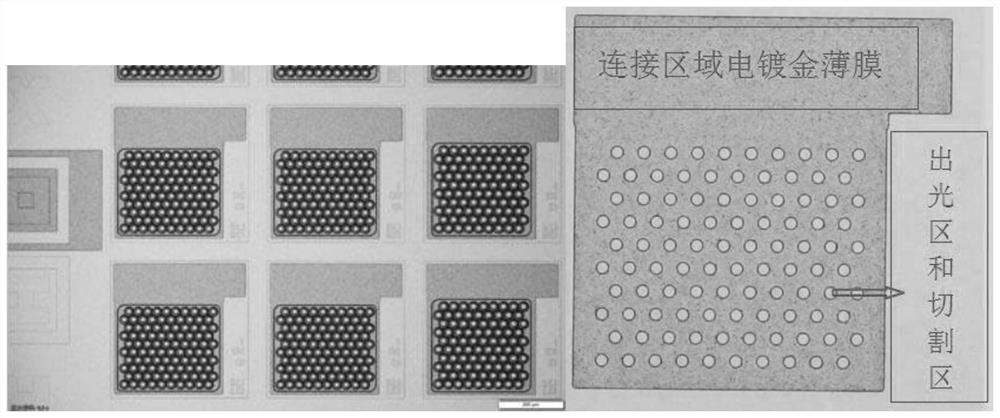

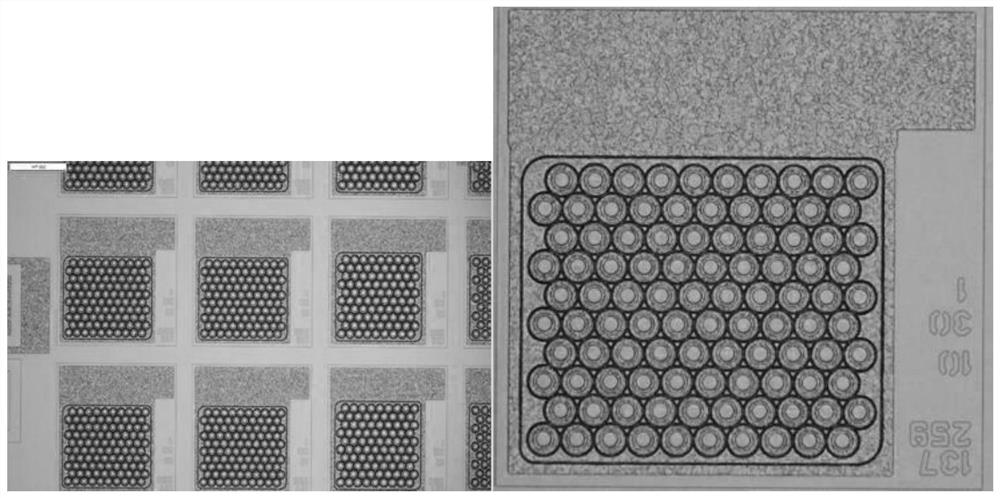

[0025] Taking the wafer after the electroplating process in a certain VCSEL chip manufacturing process as an example, the gold thin film is etched, as shown in figure 1 As shown, there are two gold films with different thicknesses on the surface of the wafer. figure 1 Among them, the area with small black spots is the electrode connection area, and its surface is an electroplated gold film with a thickness of about 3.5um; the rest of the area is the light emitting area and the cutting area, and its surface is a sputtered gold film with a thickness of about 200nm. In the following embodiments, the 200nm gold film will be etched away using an etchant, that is, the gold film in the light emitting area and the cutting area will be completely etched away.

[0026] In the iodine-potassium iodide-water solution in the following examples, every 1L of water contains the iodine of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com