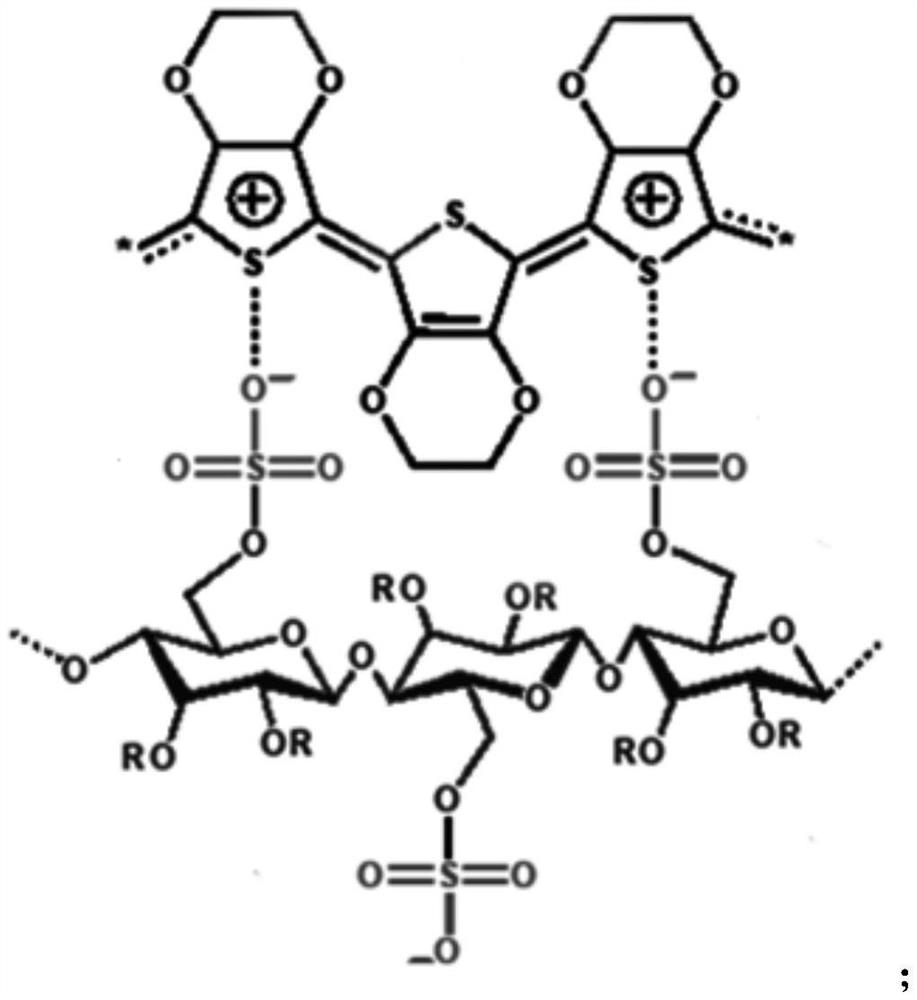

PEDOT:CS water dispersion system taking cellulose sulfate as template and preparation method of PEDOT:CS water dispersion system

A technology of cellulose sulfate and dispersion system, applied in the field of PEDOT:CS water dispersion system and its preparation, can solve the problems such as the decrease of the conductivity of PEDOT system, achieve high PEDOT content and conductivity, reduce damage, and broaden the research direction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add 20 g of sulfamic acid and 4 g of pine pulp cellulose into 100 g of DMF, and react at 90° C. for 4 hours. The solid obtained after filtering the reaction solution is added into deionized water to fully dissolve, then filtered, the filtrate is added to absolute ethanol to precipitate cellulose sulfate, and the obtained solid is freeze-dried after filtering again to obtain cellulose sulfate.

[0044] Add 1g of cellulose sulfate into 100g of deionized water, add 2g of EDOT monomer, stir and disperse for 1h. Then 5 g of ammonium persulfate and 0.2 g of ferric chloride were added, and polymerized for 18 hours under a nitrogen atmosphere, and the polymerization reaction temperature was 35° C. The blue-black aqueous dispersion obtained after the reaction is the PEDOT:CS aqueous dispersion system using cellulose sulfate as a template.

Embodiment 2

[0046] Add 5 g of sulfamic acid and 1 g of pine pulp cellulose into 100 g of DMF, and react at 70° C. for 2 hours. The solid obtained after filtering the reaction solution is added into deionized water to fully dissolve, then filtered, the filtrate is added to absolute ethanol to precipitate cellulose sulfate, and the obtained solid is freeze-dried after filtering again to obtain cellulose sulfate.

[0047] Add 1g of cellulose sulfate into 100g of deionized water, add 0.5g of EDOT monomer, stir and disperse for 1h. Then add 0.75g of ammonium persulfate and 0.025g of ferric chloride, and polymerize for 6 hours under nitrogen atmosphere, and the polymerization reaction temperature is 20°C. The blue-black aqueous dispersion obtained after the reaction is the PEDOT:CS aqueous dispersion system using cellulose sulfate as a template.

Embodiment 3

[0049]Add 10 g of sulfamic acid and 2 g of pine pulp cellulose into 100 g of DMF, and react at 80° C. for 4 hours. The solid obtained after filtering the reaction solution is added into deionized water to fully dissolve, then filtered, the filtrate is added to absolute ethanol to precipitate cellulose sulfate, and after filtering again, the obtained solid is freeze-dried to obtain cellulose sulfate.

[0050] Add 1g of cellulose sulfate into 100g of deionized water, add 1g of EDOT monomer, stir and disperse for 1h. Then add 2g of ammonium persulfate and 0.06g of ferric chloride, and polymerize for 12 hours under nitrogen atmosphere, and the polymerization reaction temperature is 25°C. The blue-black aqueous dispersion obtained after the reaction is the PEDOT:CS aqueous dispersion system using cellulose sulfate as a template.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com