Glass fiber melting and infiltrating device

A technology of glass fiber and infiltration device, which is applied in the field of glass fiber processing, and can solve problems such as easy blockage of infiltration equipment, poor infiltration effect, and low product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

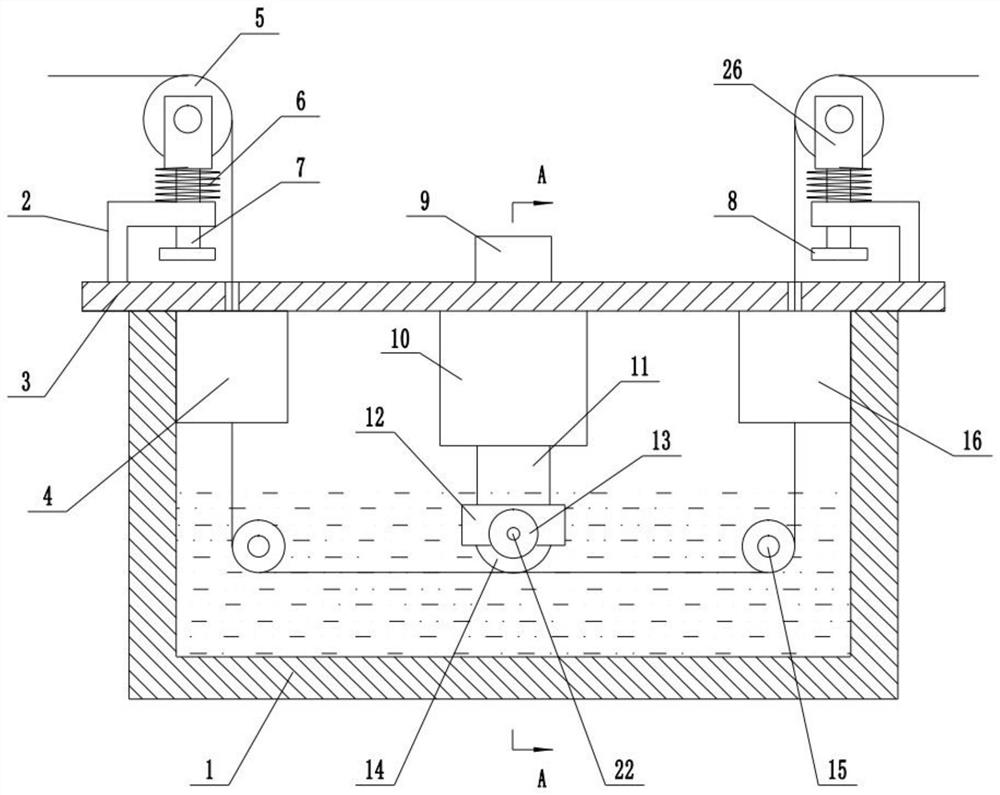

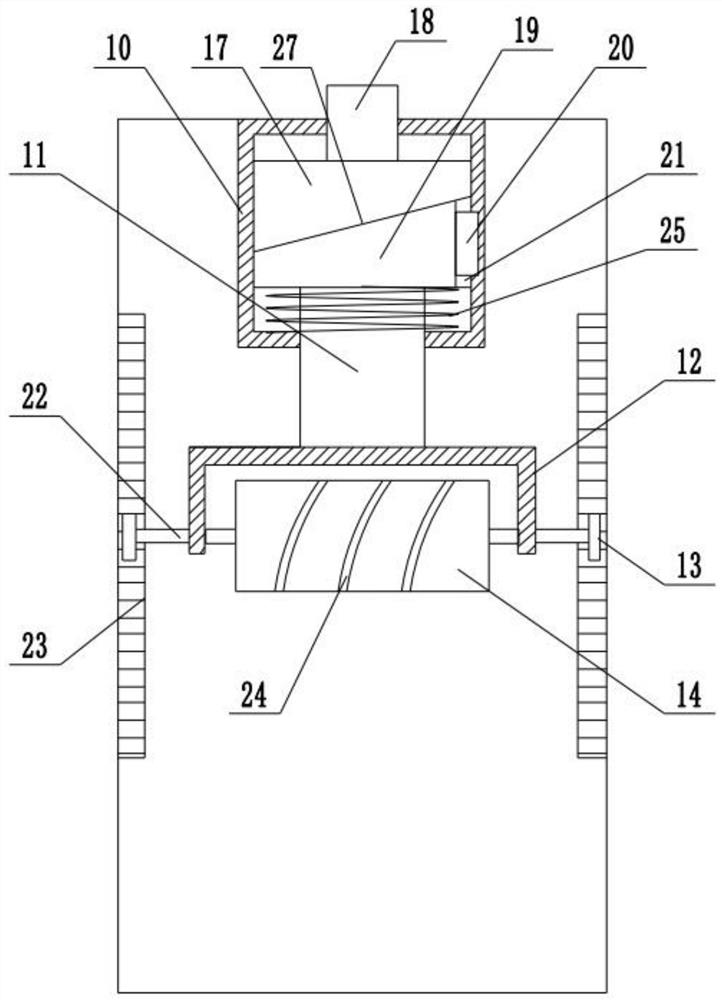

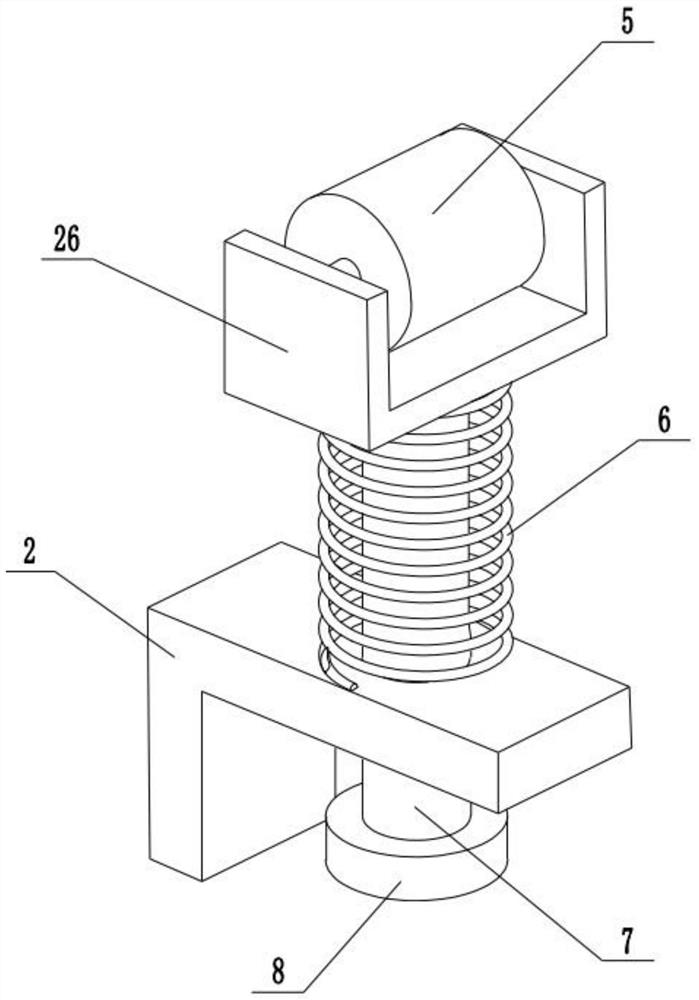

[0028]SeeFigure 1~3In the embodiment of the present invention, a glass fiber melting infiltration device includes an infiltration box 1, a box plate 3 is installed at the top of the infiltration box 1, and a reaction box 4 is installed on the left side of the lower end of the box plate 3, and the inside of the reaction box 4 It is filled with a compatibilizer to cause a graft reaction with the glass fiber. A number of wetting grooves 24 are provided on the outside of the rotating roller 14 to hold the moving glass fiber so that it can fully react with the wetting agent. 3 A cooling box 16 is installed on the right side of the lower end. The cooling box 16 is equipped with a semiconductor refrigeration mechanism for cooling the infiltrated glass fiber. Both sides of the upper end of the box plate 3 are installed with an L-shaped frame 2, and the upper end of the L-shaped frame 2 slides in the middle. A telescopic column 7 is provided, the upper end of the telescopic column 7 is conne...

Embodiment 2

[0030]In another embodiment of the present invention, an infiltration box 1 is included, a box plate 3 is installed at the top of the infiltration box 1, a reaction box 4 is installed on the left side of the lower end of the box plate 3, and the inside of the reaction box 4 is filled with a compatibilizer , The outer side of the rotating roller 14 is provided with a number of soaking grooves 24, a cooling box 16 is installed on the right side of the lower end of the box plate 3, a semiconductor refrigeration mechanism is installed inside the cooling box 16, and both sides of the upper end of the box plate 3 are installed with L-shaped frames 2. The upper middle of the L-shaped frame 2 is provided with a telescopic column 7 slidably, the upper end of the telescopic column 7 is connected with a transmission frame 26, the upper middle of the transmission frame 26 is rotatably provided with a transmission wheel 5, and the outer side of the telescopic column 7 between the transmission fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com