Telescopic loading and unloading equipment

A technology for loading and unloading equipment and driving devices, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of difficult maintenance, complicated folding and storage principles, etc., and achieve the effect of solving the problem of loading and unloading vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

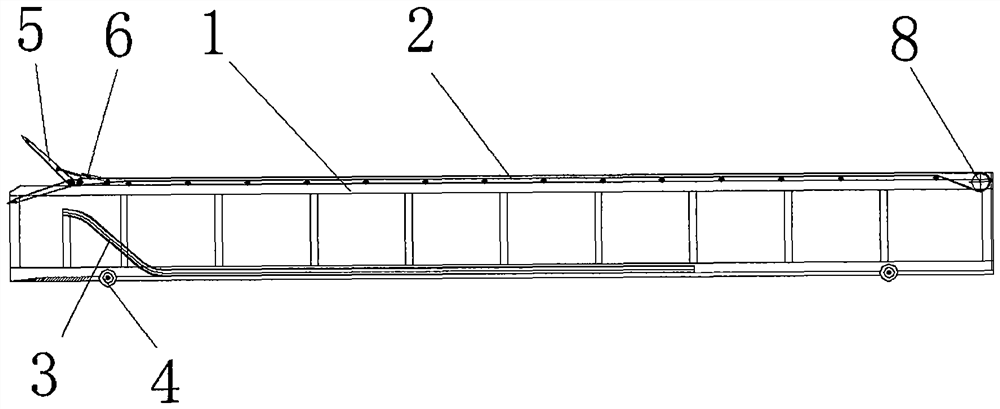

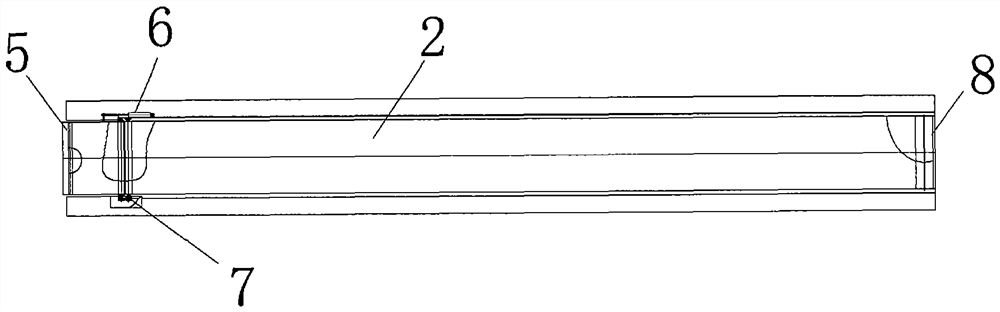

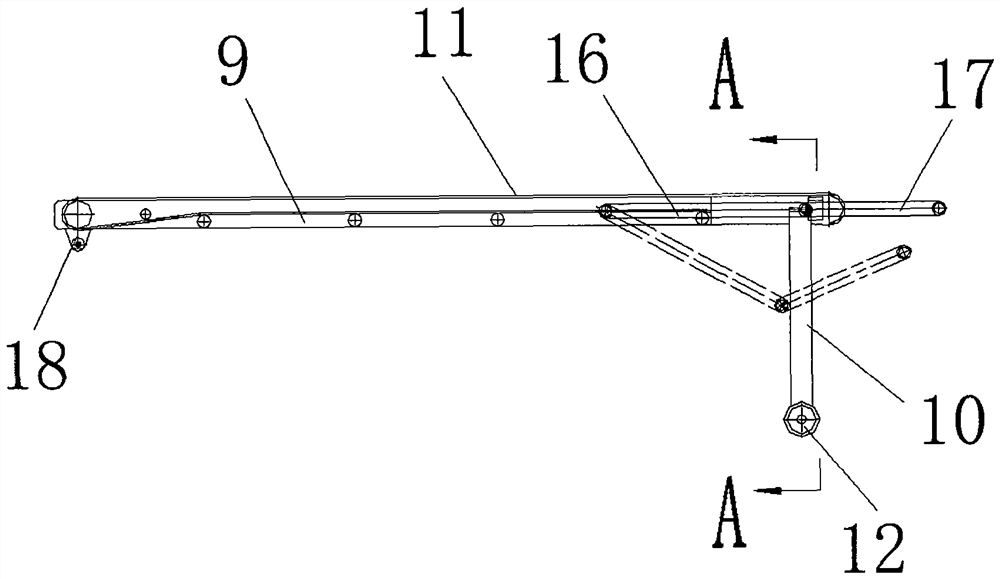

[0037] Below in conjunction with accompanying drawing, the present invention will be further described, as Figure 13 As shown, a telescopic loading and unloading equipment includes:

[0038] like figure 1 and figure 2 As shown, the frame body 1, the top of the frame body 1 is provided with a conveyor belt 2, the bottom of the frame body 1 is provided with a trolley slide rail 3, and the position of the trolley slide rail 3 near the front is tilted upward; The bottom of the frame body 1 is provided with a roller 4 for promoting the entire telescopic loading and unloading equipment (when storing), and a short belt frame 5 is hingedly arranged on the front portion of the frame body 1, and a conveyor belt is arranged on the short belt frame 5. Since the telescopic trolley There is a height difference with the conveyor belt 2, so the short belt frame 5 is used as a connecting bridge to ride on the telescopic trolley; the top beam and the bottom beam of the frame body 1 are fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com