A movable pedal board

A movable board and mobile technology, which is applied in the field of pedal boards and movable pedal boards, to avoid modification, reduce equipment or infrastructure investment, and achieve good bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

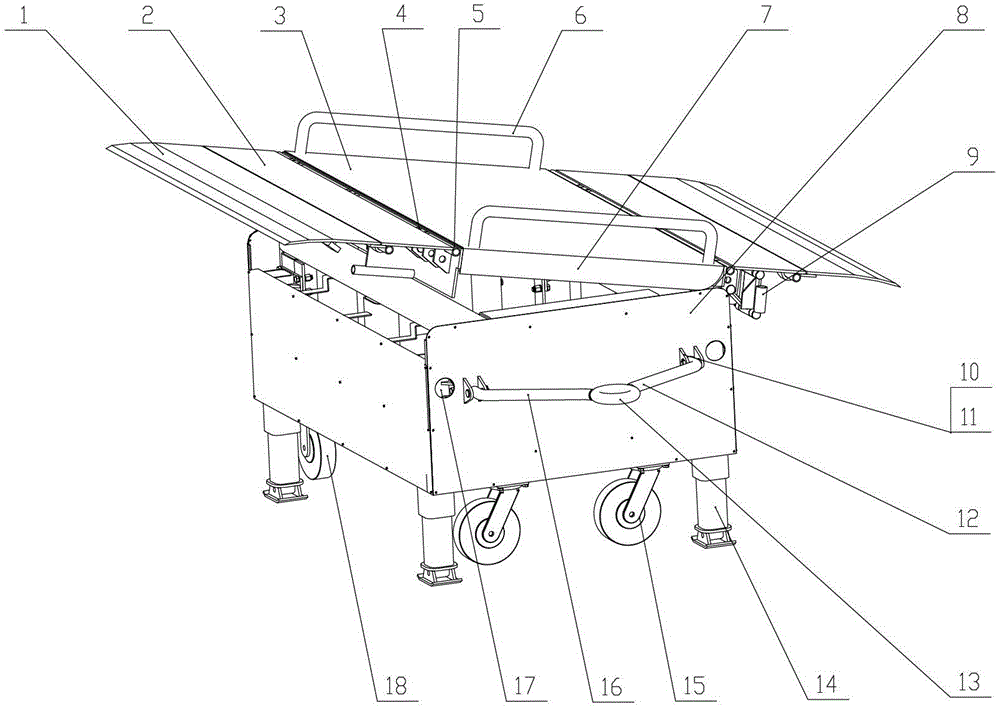

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

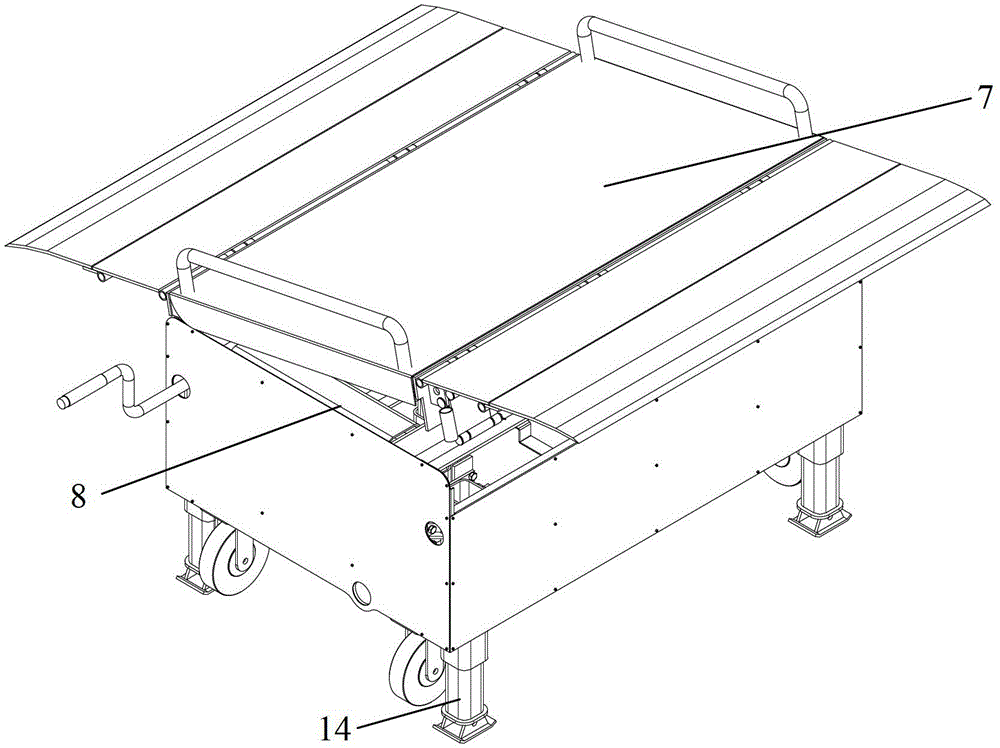

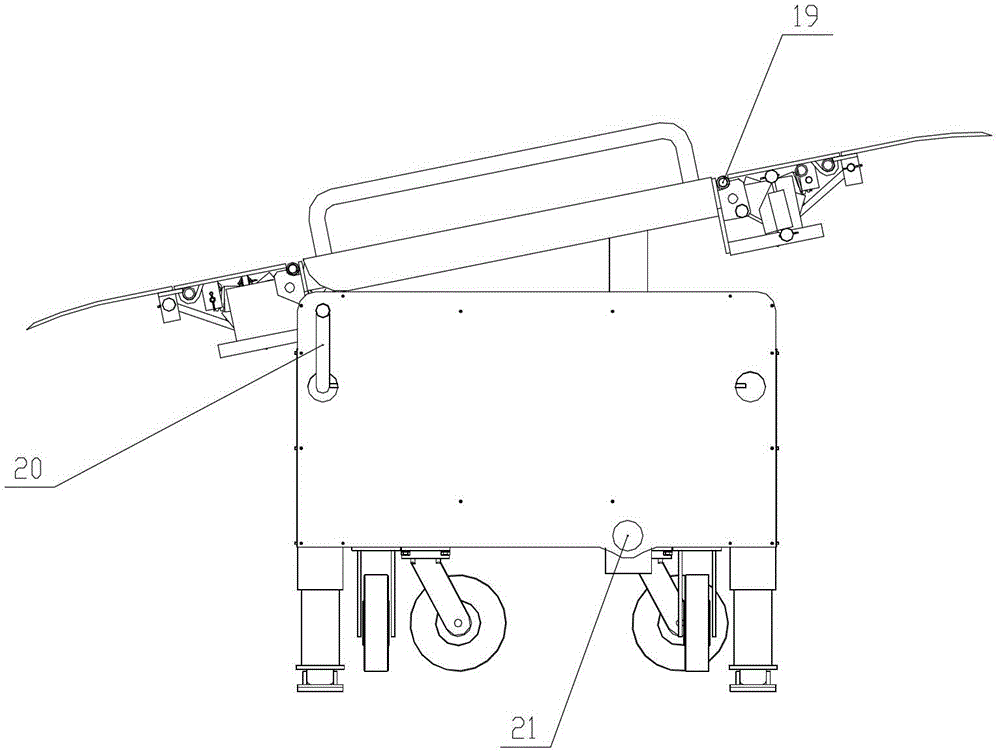

[0028] see figure 1 : the movable pedal board of the present invention comprises an upper movable platform 7, a base 8, and jacking legs 33; the lower side of the upper movable platform 7 is connected with the base 8 by a rotating shaft structure, and the upper movable platform 7 can rotate around The rotating shaft structure tilts and flips on the base 8 at an angle to the horizontal plane; the jacking legs 33 are connected between the movable platform 7 and the base 8 to drive the tilting and flipping of the upper movable platform 7 .

[0029] Each part that forms the present invention is described in detail below in conjunction with accompanying drawing:

[0030] Upper activity platform 7

[0031] see figure 2 , 3 and Image 6 : upper movable platform 7 of the present invention comprises tongue plate 1, movable plate 2, upper panel 3; The two sides of upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com