Driving structure of electric locomotive

A driving structure and technology for electric locomotives, applied in electric locomotives, transmissions driven by electric motors, locomotives, etc., can solve problems such as easy failure, environmental pollution, loss, etc., to eliminate pollution and noise, improve flexibility, and reliability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

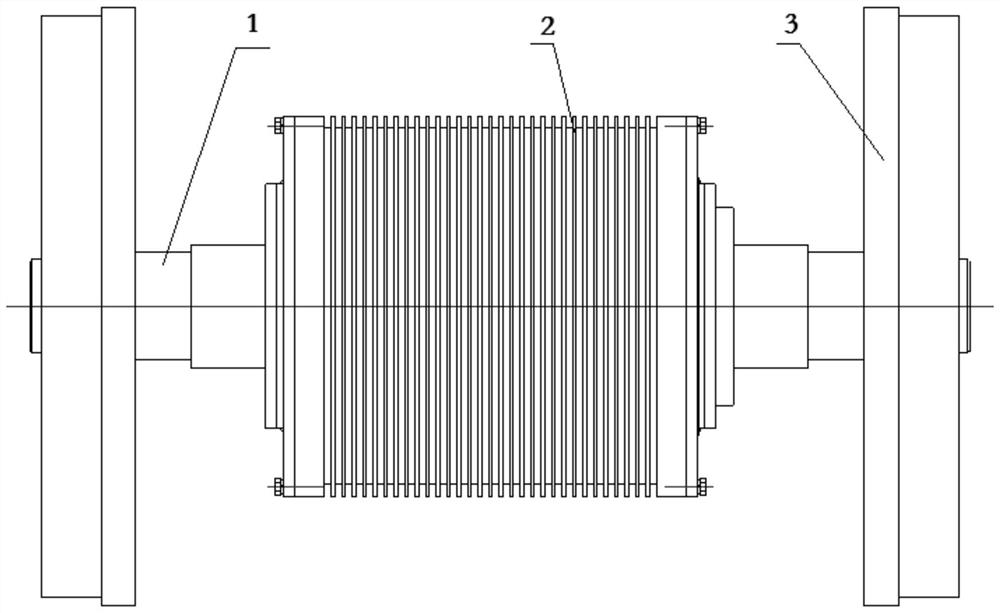

[0026] This embodiment provides a driving structure of an electric locomotive, such as figure 1 As shown, it includes a locomotive axle 1 and an axle direct drive motor 2, the power shaft of the axle direct drive motor 2 is the same as the locomotive axle 1, and the axle direct drive motor 2 is arranged on the locomotive axle 1 In the middle part, two ends of the locomotive axle 1 are respectively equipped with locomotive wheels 3; it also includes a battery and a driver, and the battery is electrically connected to the axle direct drive motor 2 through the driver; it also includes a position detector, the The position detector is electrically connected with the driver.

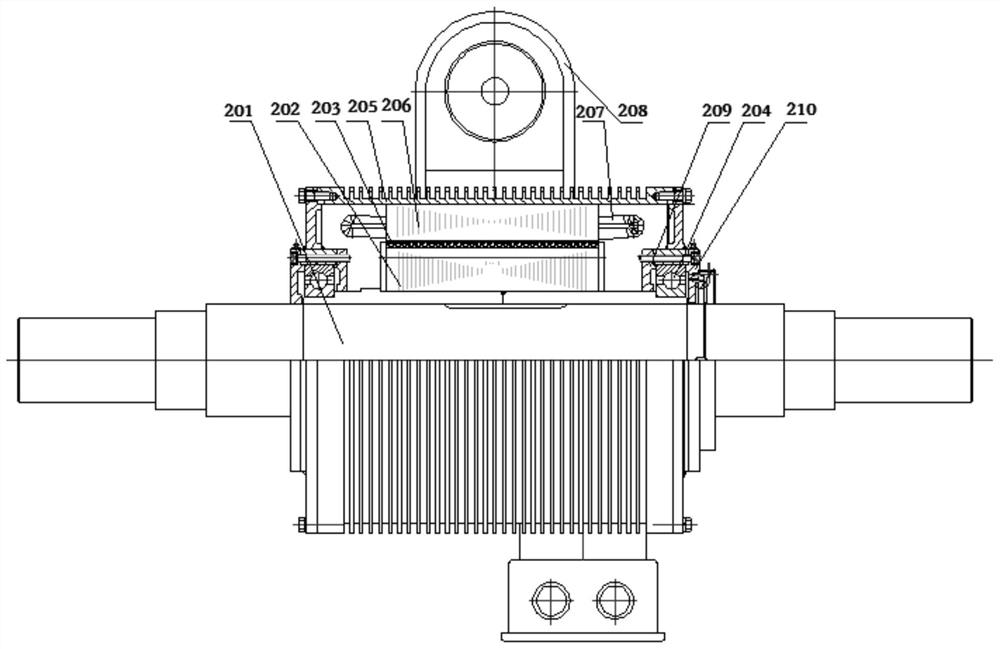

[0027] Specifically, such as figure 2 As shown, the axle direct drive motor 2 includes a motor shaft 201, the motor shaft 201 is coaxial with the locomotive axle 1 and is located in the middle of the locomotive axle 1, and the outside of the motor shaft 201 is press-fitted and fixed with A rotor core 202, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com