Automatic glass edging production line

A glass edging and production line technology, which is applied to machine tools, grinders, and workpiece supports for grinding workpiece edges, can solve problems such as low processing efficiency, improve processing quality, increase friction, and facilitate transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

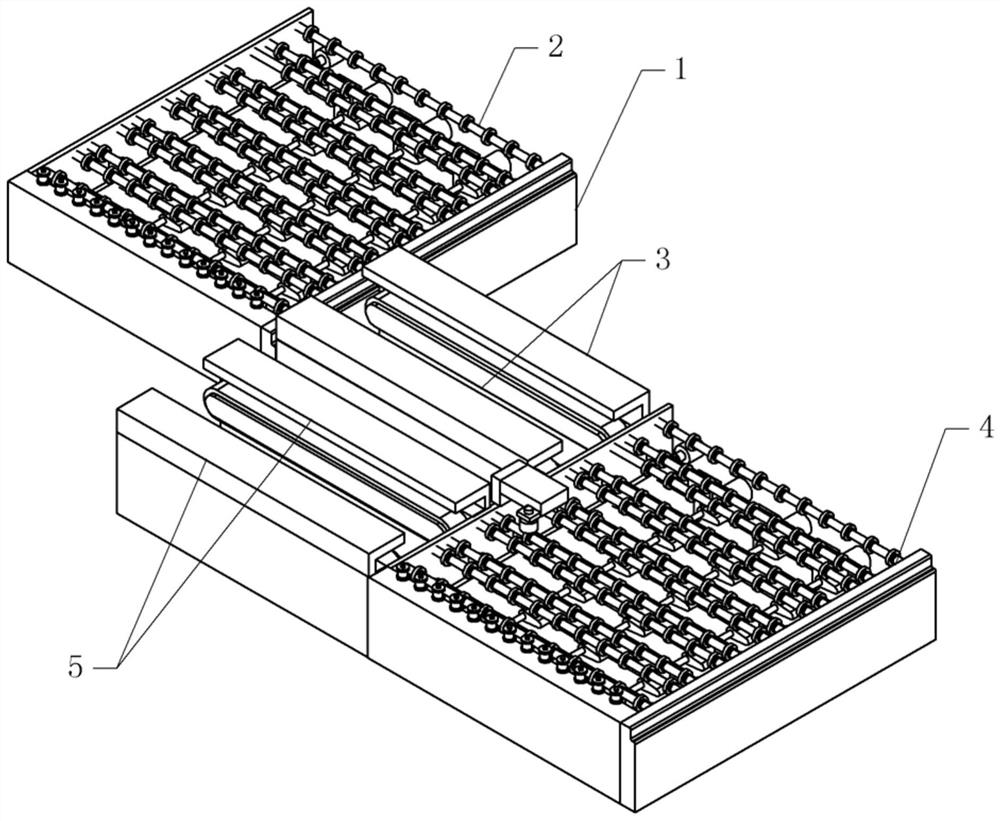

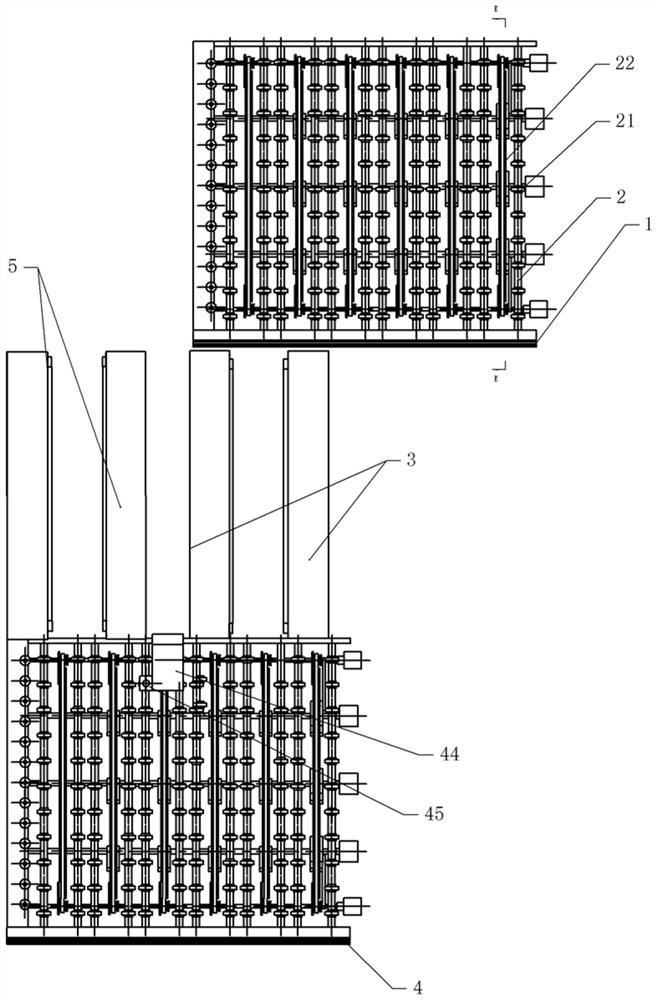

[0037] Basic as attached figure 1 And attached figure 2 Shown: an automatic glass edging production line, including a frame on which a first transmission mechanism 1 and a second transmission mechanism 4 are installed. In this embodiment, the first transmission mechanism 1 and the second transmission mechanism 4 both include The roller feeding mechanism and several belt feeding mechanisms are uniformly distributed along the length direction of the frame, and the roller feeding mechanism and the belt feeding mechanism are arranged alternately. The roller feeding mechanism conveys the glass horizontally, and the belt feeding mechanism conveys the glass longitudinally.

[0038]The end of the conveying direction of the belt feeding mechanism of the first conveying mechanism 1 is provided with a first bilateral edging device 3, and the end of the conveying direction of the belt feeding mechanism of the second conveying mechanism 4 is provided with a second bilateral edging device...

Embodiment 2

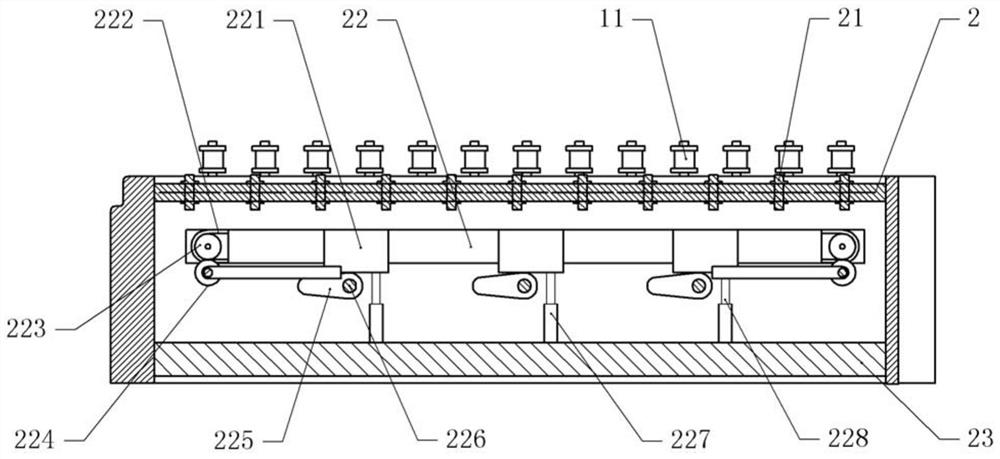

[0045] The difference between embodiment two and embodiment one is that, as attached Figure 6 And attached Figure 7 As shown, a cavity 231 is opened in the mounting plate 23, and a pressure plate 232 is vertically slidably connected to the cavity 231, and the pressure plate 232 is fixedly connected to the inner shaft 228 by bolts. Valve 25. An air chamber 12 is arranged below the guide roller 11 on the frame, and the air chamber 12 communicates with the air outlet check valve 25 through a pipeline.

[0046] The guide roller 11 includes a support shaft that is rotatably connected with the frame. There is an air channel 13 communicating with the air chamber 12 in the support shaft. There is a communication hole 14 on the support shaft. A guide cylinder is sleeved on the support shaft, and the guide cylinder and the support An exhaust cavity 15 is formed between the shafts, and an air hole 16 is formed on the side wall of the guide cylinder, and the air hole 16 communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com