Ground flour wheat husk screening device

A screening device and wheat husk technology, which is applied in the fields of sifting, transportation and packaging, conveyor objects, etc., can solve the problems of restricting production efficiency, clogging the screen, reducing the screening effect of the screen, etc., and achieve the effect of improving the flour screening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

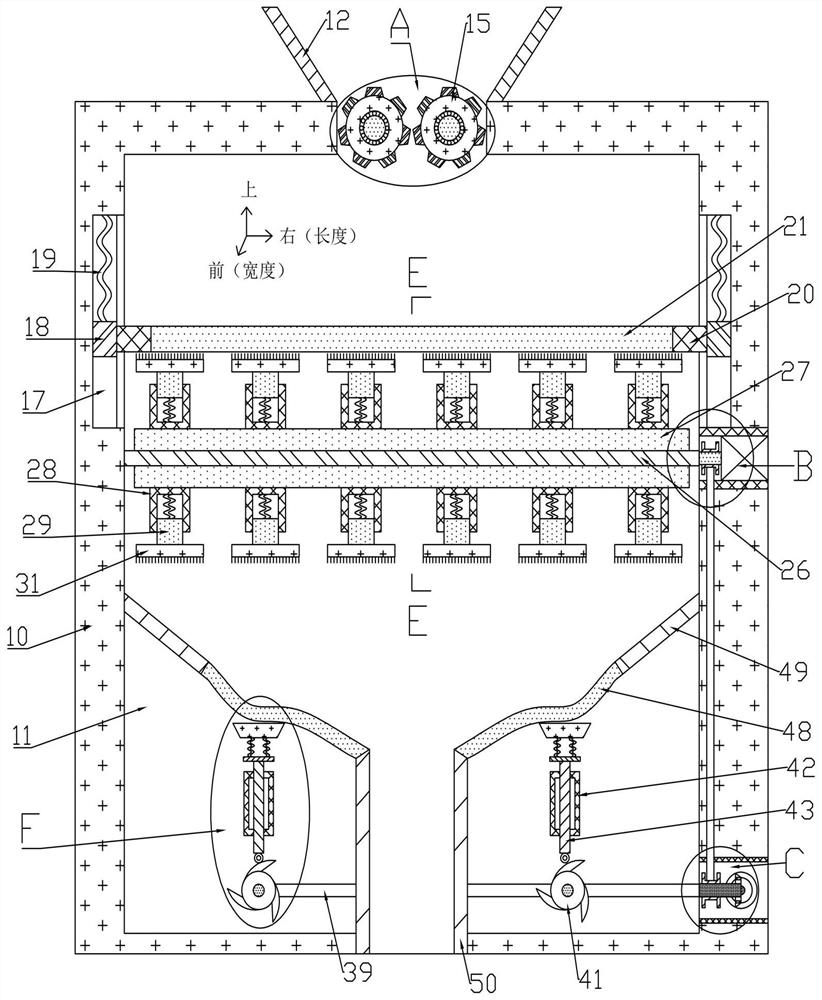

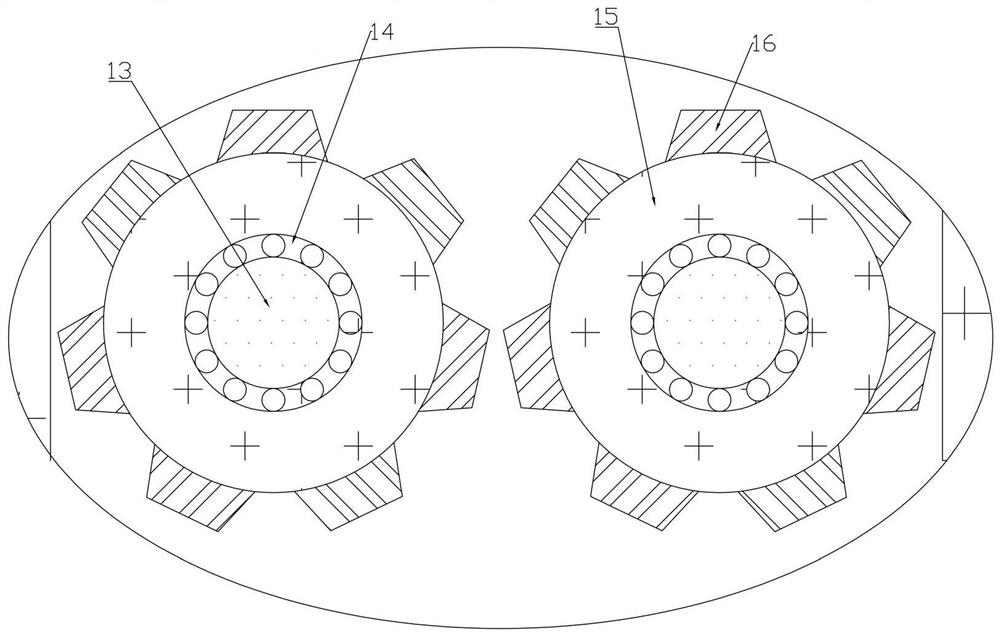

[0032] Such as figure 1 As shown, a milled flour wheat husk screening device includes a shell 10 with openings on both upper and lower sides, a working space 11 is defined in the shell 10, and an intermittent control device for controlling the flour is arranged at the upper opening of the shell 10. into the working space 11 to screen the feeding mechanism, the working space 11 is equipped with a screening mechanism for screening the wheat husks remaining in the flour, and the lower opening of the housing 10 is provided with a discharging mechanism, which is connected to the The space surrounded by the housing 10 is provided with two auxiliary mechanisms that cooperate with the discharge mechanism. The two auxiliary mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com