Flexible automatic assembling and production equipment and method for electroacoustic devices

A technology for automatic assembly and electro-acoustic devices, which is applied in mechanical equipment, connecting components, and devices for applying liquid to surfaces, etc. It can solve the problems of low production efficiency, difficult to guarantee product consistency and reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

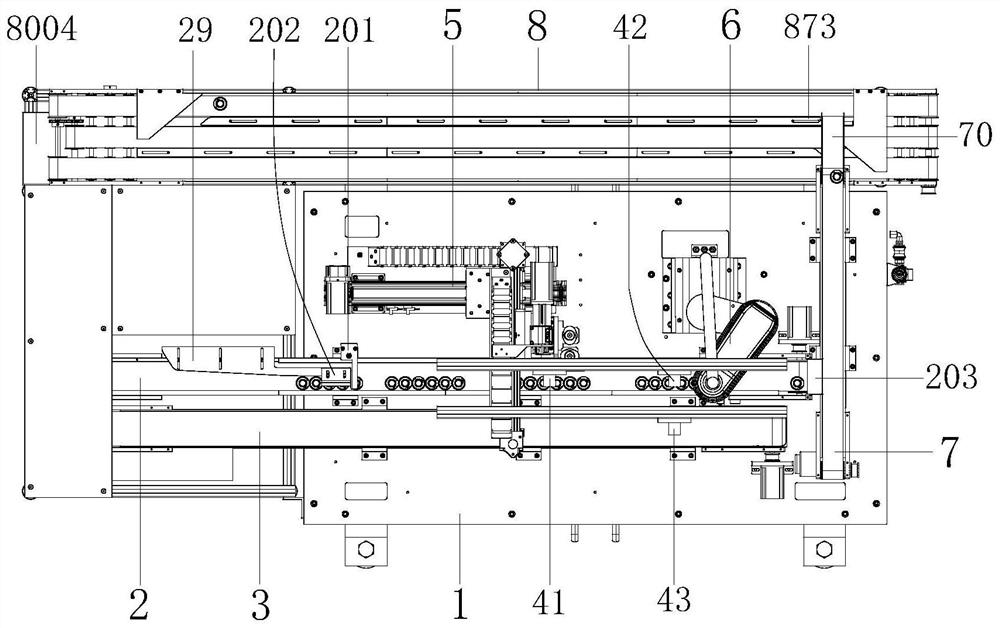

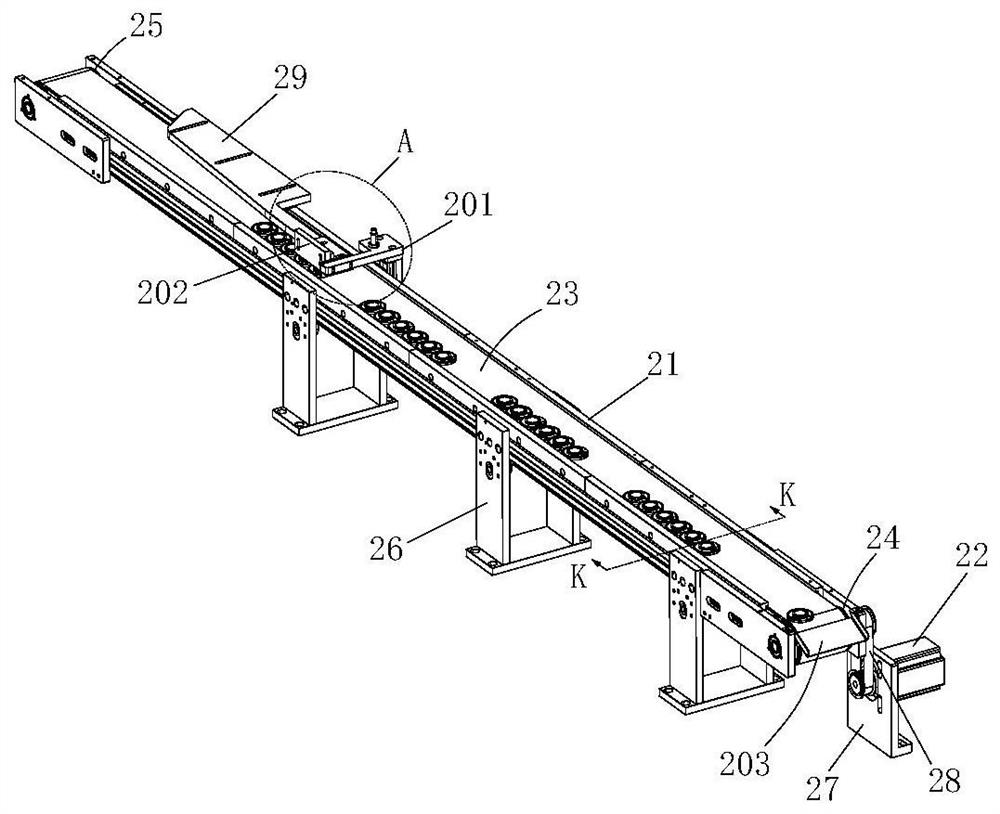

[0059] refer to Figure 1 to Figure 25 As shown, a flexible automatic assembly production equipment for electroacoustic devices provided by the present invention includes: a machine 1, a first conveying device 2, a second conveying device 3, a vision module 4, a control module, a dispensing manipulator 5 and a placement Manipulator 6. In the actual use of this equipment, the first product conveyed by the first conveying device 2 is the speaker shell, and the second product conveyed by the second conveying device 3 is the PCB board, but this equipment is not limited to the dispensing of the speaker shell and the PCB board only It can also be applied to the dispensing and placement of other products, wherein the speaker shell and the PCB board are respectively provided with feature recognition holes.

[0060] The first conveying device 2 is arranged on the machine platform 1, and the first conveying device 2 is used for conveying the loudspeaker casing.

[0061] The second con...

Embodiment 2

[0126] A production method for flexible automatic assembly of electroacoustic devices provided by the present invention, please refer to figure 1 As shown in Figure 25, the following steps are included:

[0127] The first conveying device 2 conveys the speaker housing to a first set position, and the first set position is below the first visual module 41 .

[0128] The first vision module 41 collects the image information of the speaker shell on the first set position and sends it to the control host on the control module; wherein, the speaker has a feature recognition hole.

[0129] The control host on the control module processes the received loudspeaker housing image information, and generates the spatial coordinates of the dispensing position on the loudspeaker housing, and sends the spatial coordinate information of the dispensing position to the dispensing manipulator 5, and the dispensing manipulator 5 according to the point The spatial coordinate information of the gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com