Super-waterproof straw silicon dioxide graphene composite material and preparation method thereof

A composite material and silicon dioxide technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., to achieve the effect of solving poor water resistance, preventing water molecule adhesion, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

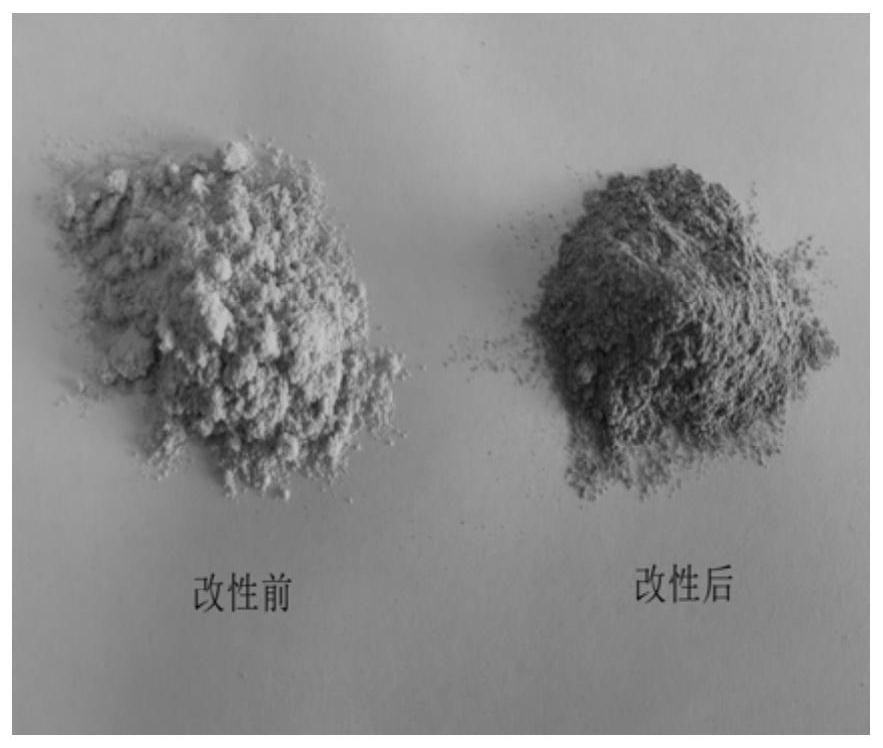

[0023] 1) Using corn stalk fiber and straw pith as the main raw materials, drying them at 100°C and preliminarily crushing them into straw granular materials with a particle size of less than 100 μm, figure 1 On the left is a photo of straw granular material.

[0024] 2) Mix 30g of straw material with 1.5g of hydrophobic nano-silicon dioxide and ball mill for 5 minutes, then add 0.5g of graphene into the mixed ball and mill for 10 minutes, the photo of the obtained composite material is as follows figure 1 shown on the right.

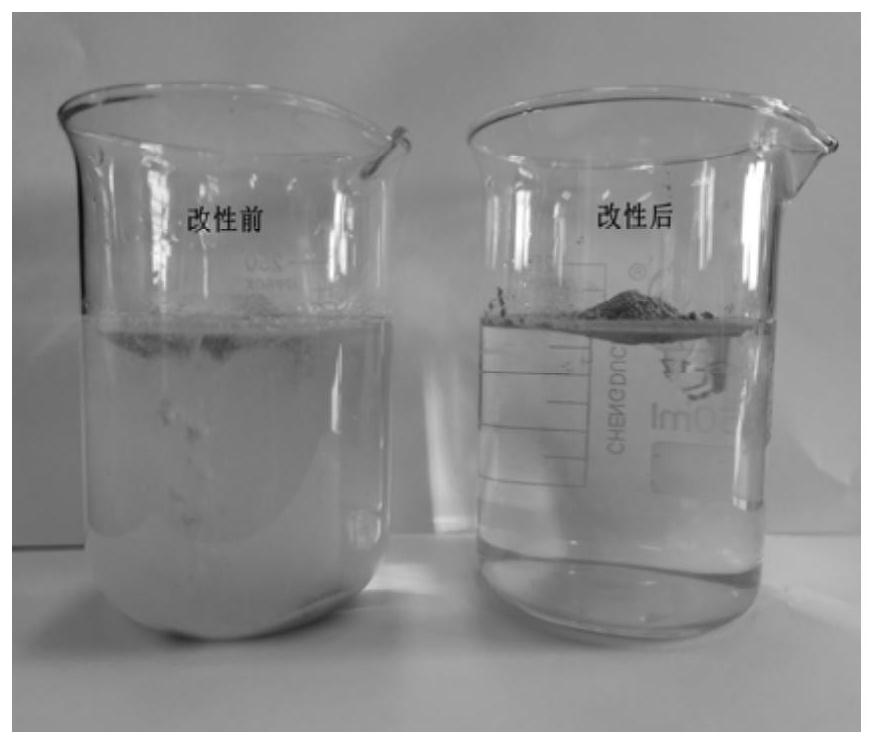

[0025] The product obtained in step 1) and step 2) is dropped into water respectively, as figure 2 As shown, the straw granular material without adding hydrophobic nano-silica and graphene for ball milling can be dispersed in water, while the composite material after adding hydrophobic nano-silica and graphene for ball milling is completely floating on the water surface. It shows that the composite material obtained after ball milling according to th...

Embodiment 2

[0028] 1) Using wheat straw fiber and straw pith as the main raw materials, drying them at 120°C and preliminarily crushing them into straw granular materials with a particle size of less than 100 μm;

[0029] 2) Mix 30g of straw material with 2.0g of hydrophobic nano-silica and ball mill for 5 minutes, then add 1.0g of graphene into the mixed ball mill for 10 minutes;

[0030] 3) The composite material was molded for 10 minutes at a pressure of 20 MPa and a temperature of 140 degrees Celsius to obtain a straw, hydrophobic nano-silica, and graphene composite material sample with a diameter of 6 mm and a thickness of 2 mm.

Embodiment 3

[0032] 1) Using rice straw fibers and straw pith as the main raw materials, drying them at 100°C and preliminarily crushing them into straw granular materials with a particle size of less than 100 μm;

[0033] 2) Mix 30g of straw material with 2.5g of hydrophobic nano-silicon dioxide and ball mill for 5 minutes, then add 1.5g of graphene into the mixed ball mill for 10 minutes;

[0034] 3) The composite material was molded for 10 minutes at a pressure of 20 MPa and a temperature of 150 degrees Celsius to obtain a straw, hydrophobic nano-silica, and graphene composite material sample with a diameter of 6 mm and a thickness of 2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com