Cement kiln scr denitrification system high temperature dust collection ash cooling system and method

A technology for dust collection and cement kiln, applied in the field of SCR denitration system, can solve the problems of high cost of purchasing equipment, poor dust collection and cooling effect, etc., to save power consumption and operating costs, improve conveying performance, and reduce equipment selection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

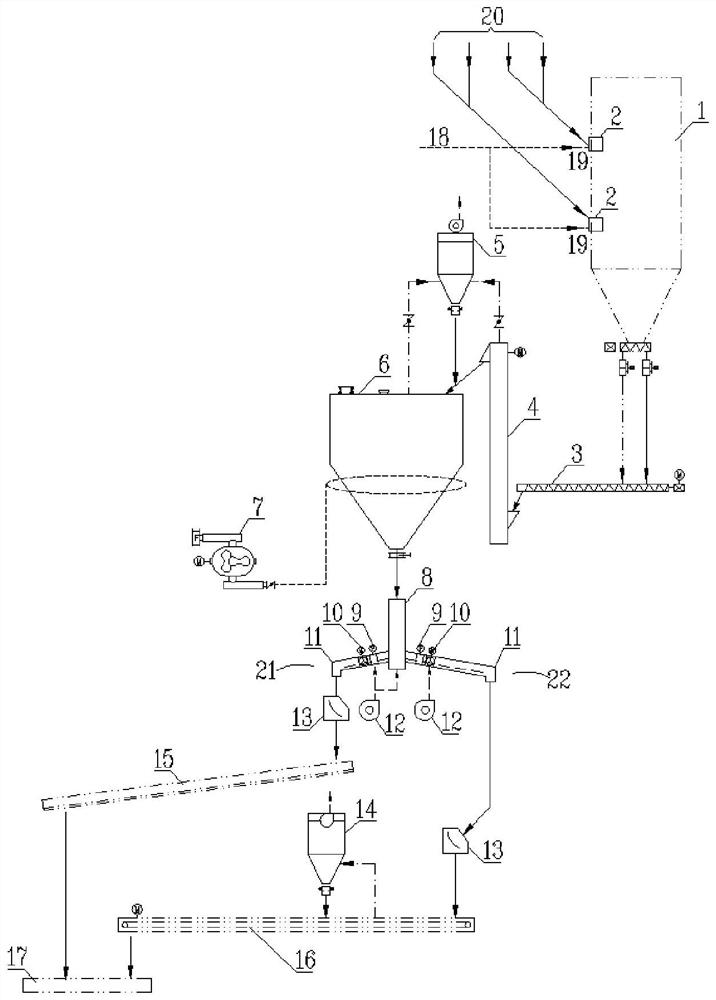

[0050] see figure 1 , the present embodiment proposes a cement kiln SCR denitrification system high-temperature dust collection ash cooling system, which includes the original cooling adjustment device 1 of the cement kiln system, an air delivery chute 15 and a chain conveyor 16, and also includes a screw conveyor 3, Bucket elevator 4, kiln dust buffer bin 6, Roots blower 7, inflatable distribution box 8 and air conveying chute 15.

[0051] Set up dust collecting ash entrance 19 on cooling adjustment device 1, be used to pass into the dust collecting ash 20 from SCR denitrification tower and dust collector; The entrance and the outlet of the bucket elevator 4 are connected to the kiln dust buffer bin 6; the outlet of the kiln dust buffer bin 6 is connected to the inflatable distribution box 8; The second road 22 is connected to the chain conveyor 16; the outlet of the air delivery chute 15 and the outlet of the chain conveyor 16 are connected to the kiln dust hoist 17 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com