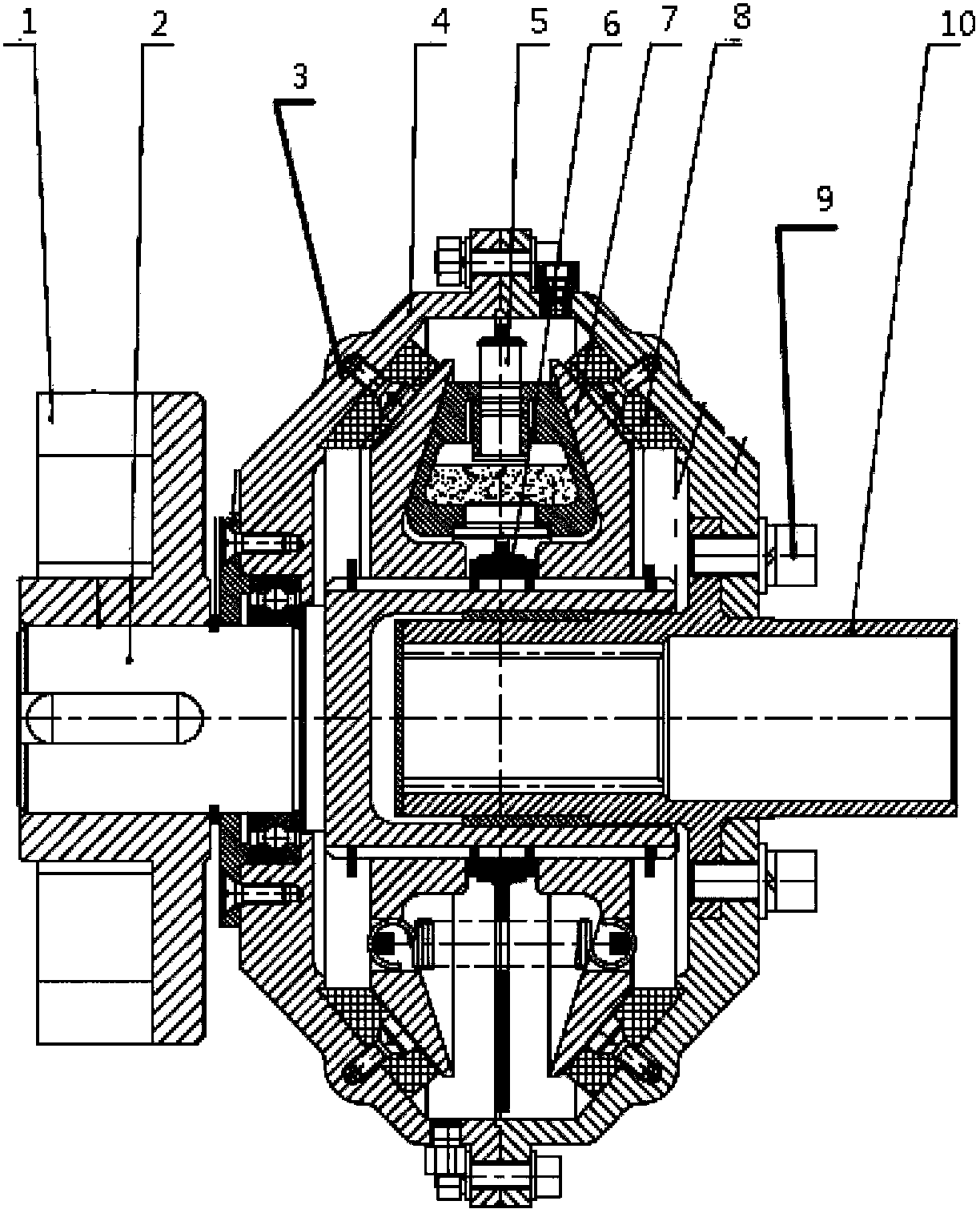

Long-acting temperature control friction coupler

A coupling, long-term technology, applied in clutches, automatic clutches, mechanical equipment and other directions, can solve the problems of high material cost, complex production process, small friction coefficient, etc., achieve large friction coefficient, simple production process, reduce material cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the features, technical means and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

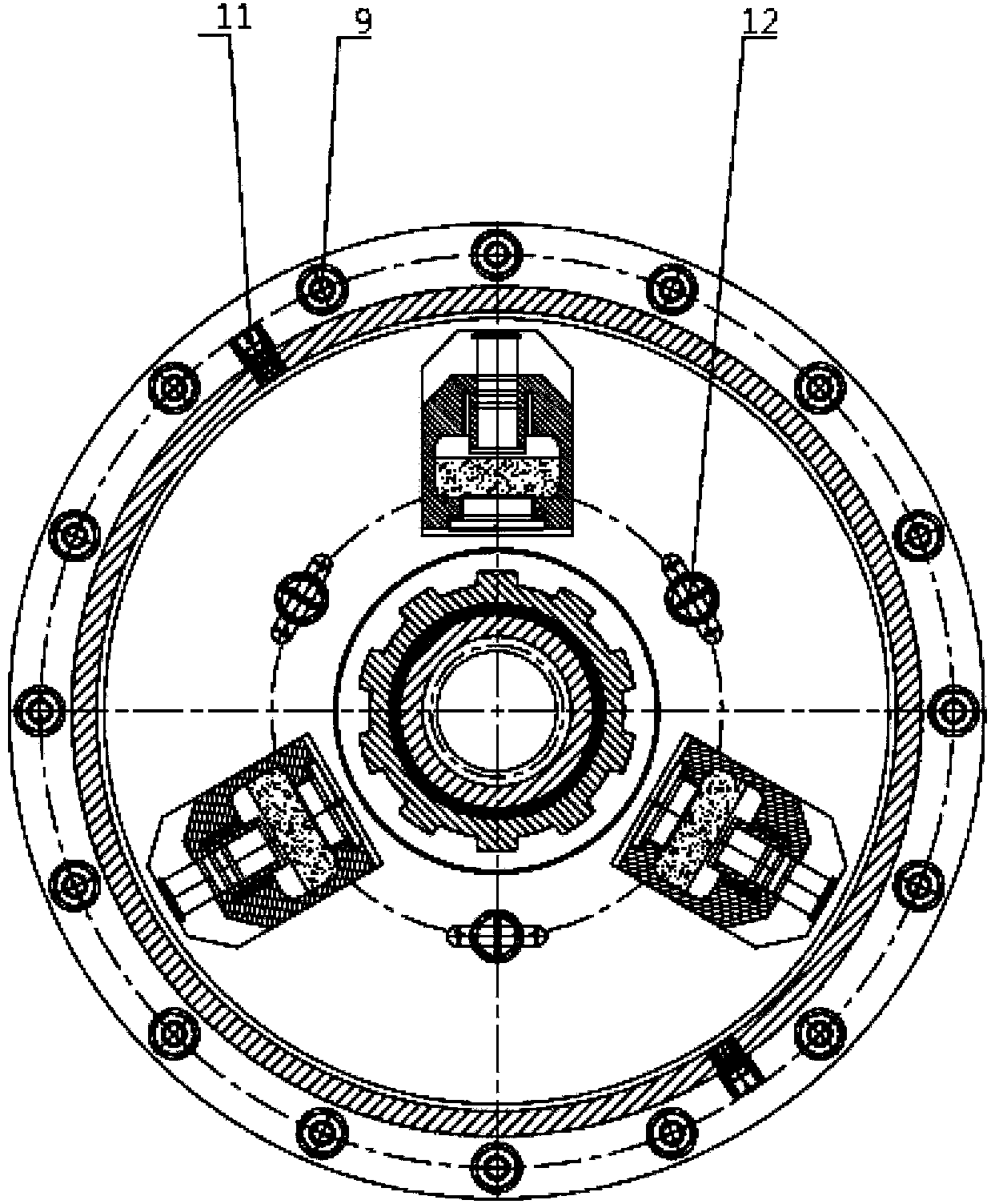

[0016] according to figure 1 , 2 As shown, a long-term temperature-controlled friction coupling includes a half coupling 1, a spline shaft 2, a friction ring 4, a positioning spline 6, a fixing bolt 9, an inner spline sleeve 10, a spline friction plate 7, Sewage heat dissipation valve 11, under the action of centrifugal force, the wedge-shaped block 5 in the working condition slides axially to overcome the resistance of the circlip, so that the left clutch 3 and the right clutch 9 are in contact with the friction ring, and the spline friction disc 8 heats up, and the temperature Pass it to the working condition wedge block 5, causing the liquid in the working condition wedge block 5 to expand, pushing the piston out, and under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com