Industrial dedusting, desulfurizing, denitrifying and purifying chimney structure

A desulfurization and denitrification, chimney technology, applied in the direction of chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of chimney emission pollution, large investment costs, single overall structure, etc., to achieve the effect of ensuring the purification quality and facilitating the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

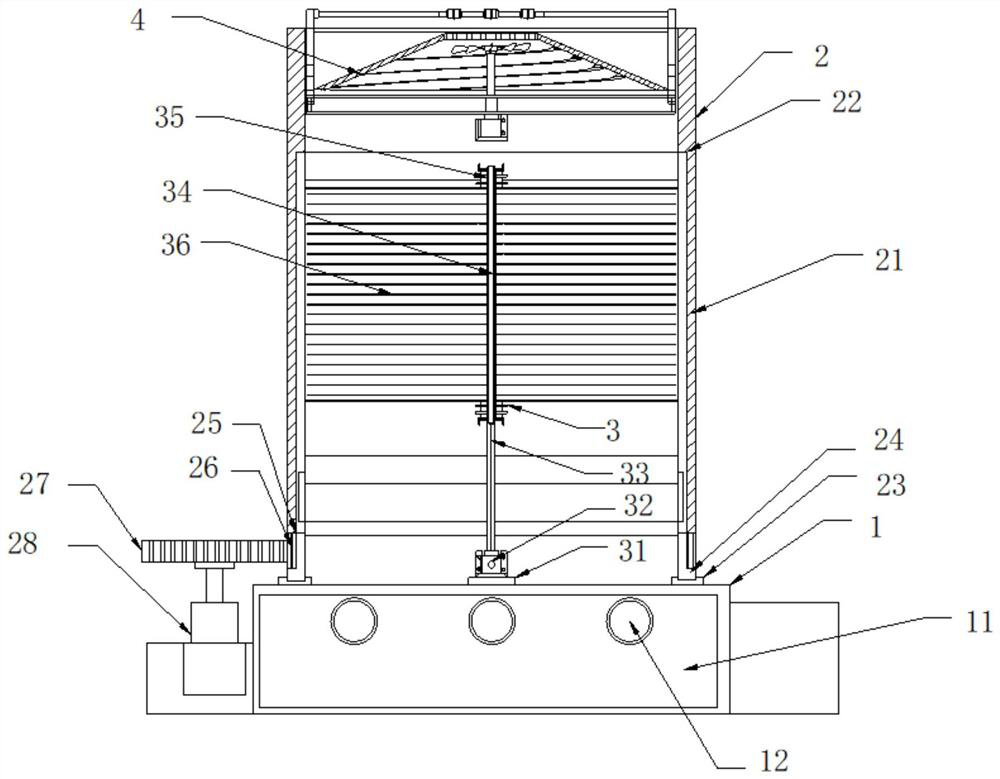

[0027] see figure 1 , an industrial dedusting, desulfurization, denitrification and purification chimney structure, including a base 1 and a chimney tube 2, the chimney tube 2 is installed on the base 1, the inner cavity of the base 1 is provided with a reservoir 11, the base A number of air inlet pipes 12 are arranged in the installation cavity of the seat 1 and the chimney tube 2, the chimney tube 2 includes an outer shell tube 21 and an inner tank tube 22, the inner cavity of the inner tank tube 22 is provided with a spray rack 3, The midline position of the spray frame 3 is provided with an infusion pipeline 34, and the top of the infusion pipeline 34 is provided with a solution nozzle 35, and the solution nozzle 35 is 360 ° of water outlet, and the spray frame 3 is provided with several channels Horizontal net plate 36, the horizontal net plate 36 is arranged in a superimposed manner along the infusion pipeline 34, and a water inlet frame 31 is also arranged in the chimne...

Embodiment 2

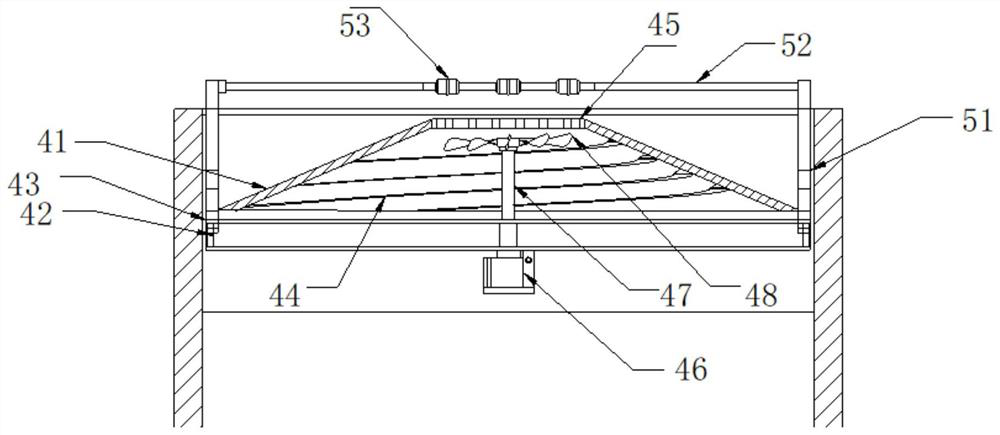

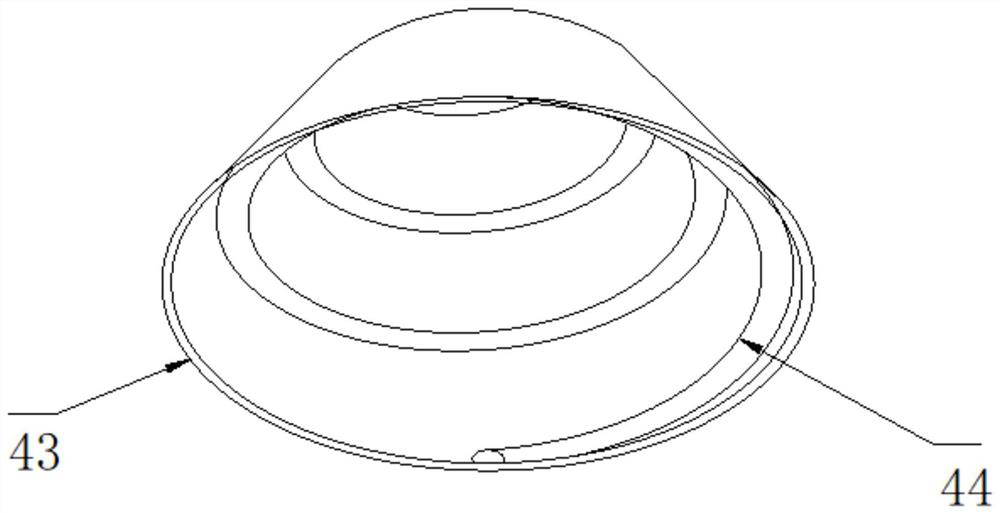

[0031] see figure 2 and image 3 , this embodiment is further optimized as Embodiment 1. On the basis of it, the top of the chimney tube 2 is provided with a top frame mechanism 4, and the top frame mechanism 4 is provided with a pot-shaped top cover 41, and the pot-shaped The top cover 41 is closed on the top of the chimney tube 2 in an upside-down style. The top of the chimney tube 2 is provided with a fixed frame 42, and the side edge of the bottom opening of the basin-shaped top cover 41 is provided with a frame edge strip 43. The frame side bar 43 is installed on the edge of the fixed frame 42, the top of the basin-shaped top cover 41 is provided with an air outlet mesh plate 45, the inside of the basin-shaped top cover 41 is provided with a spiral air guide plate 44, and the fixed frame The centerline position of the bottom of 42 is provided with a drainage motor 46, the driving end of the drainage motor 46 is equipped with a drive shaft 47, and a spiral fan 48 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com