MEMS galvanometer and optical system

A technology of micromirror and micromirror, which is applied in optics, optical components, instruments, etc., can solve the problems of reducing the frequency of resonant work of micromirror 4, increasing the weight of micromirror 4, and the adverse effects of temperature stability, so as to avoid fatigue Effects of failure, avoidance of adverse effects, and improvement of working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

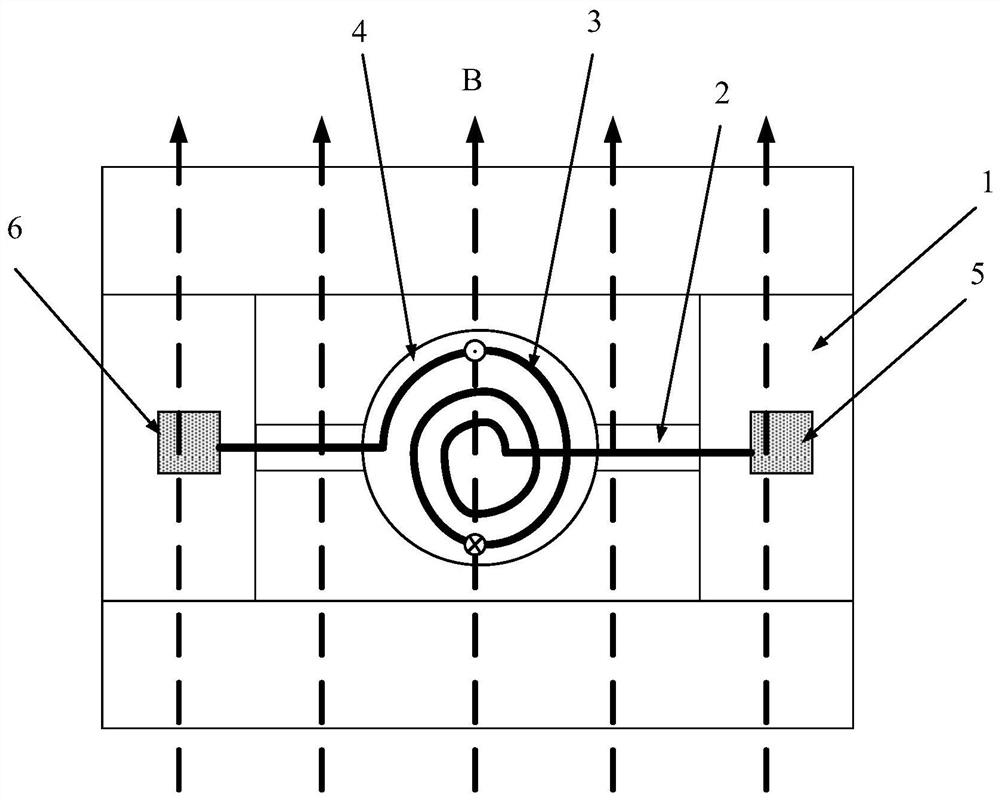

[0034] As described in the background technology, the MEMS vibrating mirror in the prior art, because the excitation coil is arranged on the surface of the micromirror, will bring many adverse effects to the normal operation of the MEMS vibrating mirror, specifically including:

[0035] 1. There are generally metal wires and dielectric materials on the rotating shaft of the mirror connected to the micromirror. These materials are deposited and prepared on the surface of the single crystal silicon rotating shaft by micromachining. The defects in these materials cause the mechanical failure of the micromirror during scanning. As the loss increases, the Q value of the mechanical resonance quality factor decreases, and the scanning angle becomes smaller; Q refers to the ratio of the mechanical energy stored by the MEMS galvanometer system at resonance to the mechanical energy consumed in one scanning cycle. Q is related to environmental damping, structure and materials of the syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com