Preparation method of ethylene glycol monovinyl ether

A technology of ethylene glycol monovinyl ether and ethylene glycol, applied in the field of preparation of ethylene glycol monovinyl ether, can solve problems such as inapplicability, and achieve the effects of less by-products, stable reaction, and low equipment pressure requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

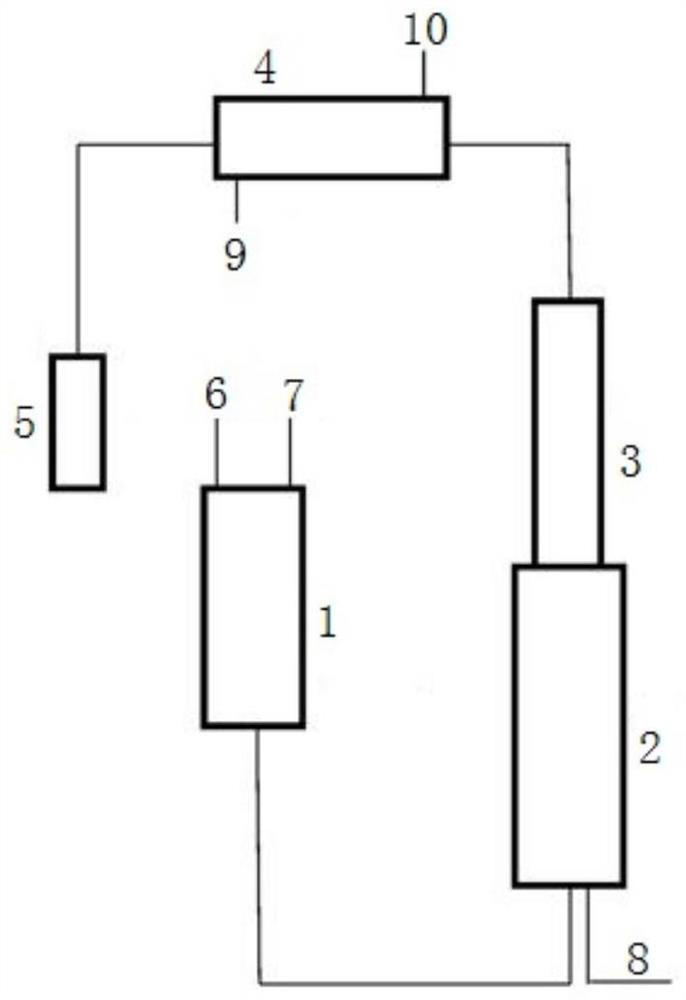

Method used

Image

Examples

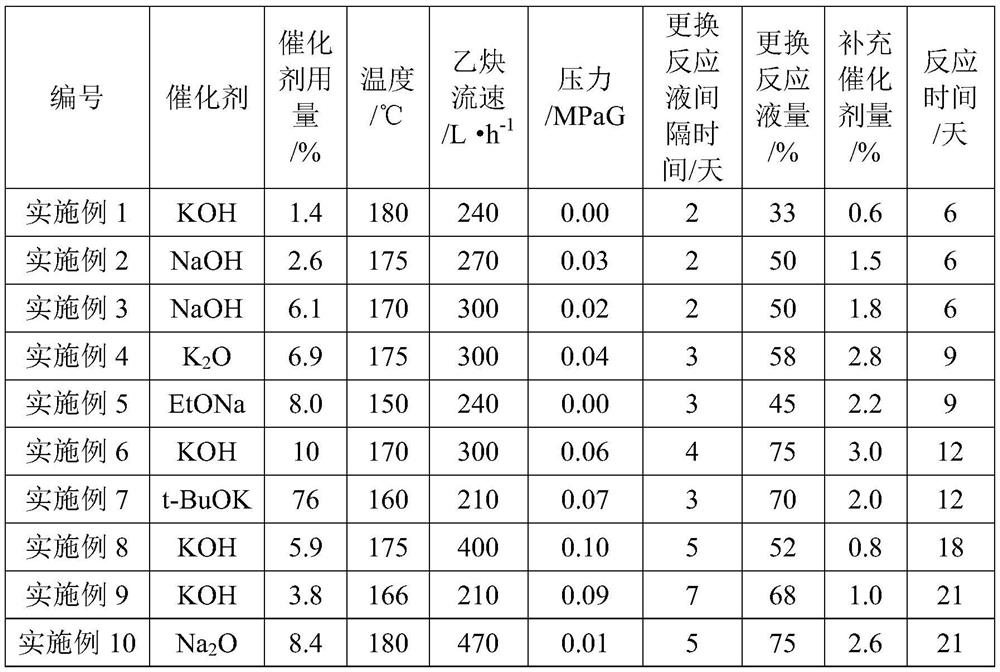

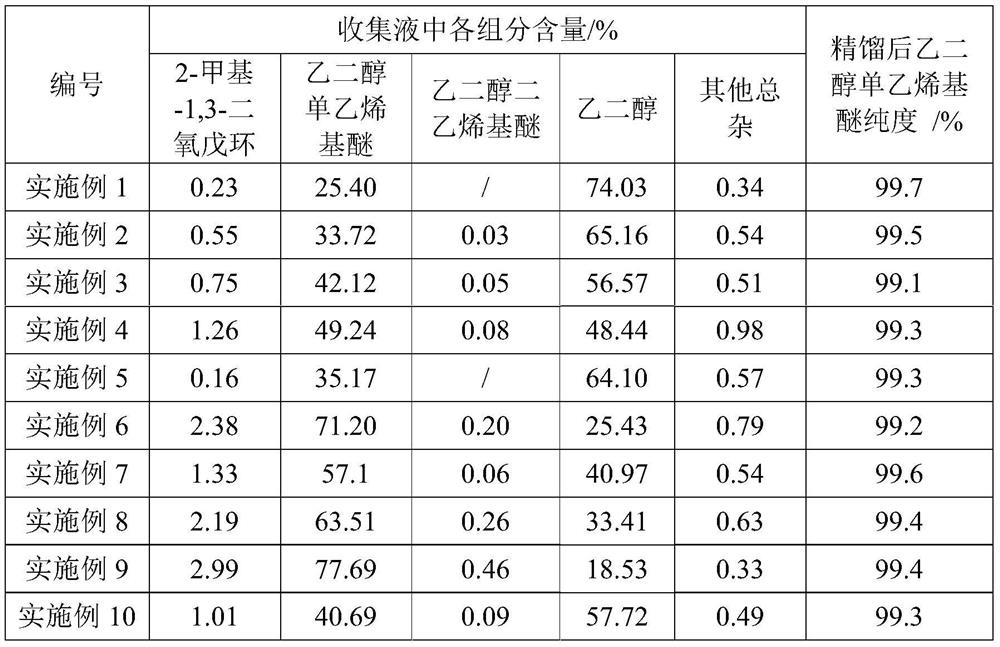

Embodiment 1

[0038] Dissolve 28g of potassium hydroxide in 2000g of ethylene glycol, add it to a 4L reactor, raise the temperature and replace it with nitrogen at the same time, then replace the nitrogen with acetylene, raise the temperature to 180°C, pressure 0MPaG, control the flow rate of acetylene to 240L / h, and react For 6 days, ethylene glycol was continuously added during the reaction process, and ethylene glycol was preheated by the preheater and then added to the reactor to keep the reaction liquid level in the reactor unchanged, and replaced on the 2nd and 4th days 651g of reaction solution and 13g of potassium hydroxide was supplemented at the same time. The new reaction solution was preheated in the preheater, and then added to the reactor. The reaction product was continuously taken out of the reactor by acetylene, and formed after distillation and condensation. Liquid, the mass content of 2-methyl-1,3-dioxolane in the collected liquid obtained in the receiver is 0.23%, the mas...

Embodiment 2

[0040] Dissolve 53g of sodium hydroxide in 2000g of ethylene glycol, add it into a 4L reactor, raise the temperature and replace it with nitrogen at the same time, then replace the nitrogen with acetylene, raise the temperature to 175°C, pressure 0.03MPaG, control the flow rate of acetylene to 270L / h, React for 6 days, add ethylene glycol continuously in the reaction process, add ethylene glycol into the reactor after being preheated by the preheater, make the liquid level of the reaction liquid in the reactor remain unchanged, and respectively in the 2nd day and the 4th day Replace 1000g of reaction solution and add 30g of sodium hydroxide at the same time. The new reaction solution is preheated in the preheater, and then added to the reactor. The reaction product is continuously taken out of the reactor by acetylene, and formed after distillation and condensation. Collected liquid, the mass content of 2-methyl-1,3-dioxolane in the collected liquid obtained in the receiver is ...

Embodiment 3

[0042] Dissolve 122g of sodium hydroxide in 2000g of ethylene glycol, add it to a 4L reactor, raise the temperature and replace it with nitrogen at the same time, then replace the nitrogen with acetylene, raise the temperature to 170°C, pressure 0.02MPaG, control the flow rate of acetylene to 300L / h, React for 6 days, add ethylene glycol continuously in the reaction process, add ethylene glycol into the reactor after being preheated by the preheater, make the liquid level of the reaction liquid in the reactor remain unchanged, and respectively in the 2nd day and the 4th day Replace 1000g of reaction solution and add 35g of sodium hydroxide at the same time. The new reaction solution is preheated in the preheater, and then added to the reactor. The reaction product is continuously taken out of the reactor by acetylene, and formed after distillation and condensation. Collection liquid, the mass content of 2-methyl-1,3-dioxolane in the collection liquid obtained in the receiver is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com